Hi all,

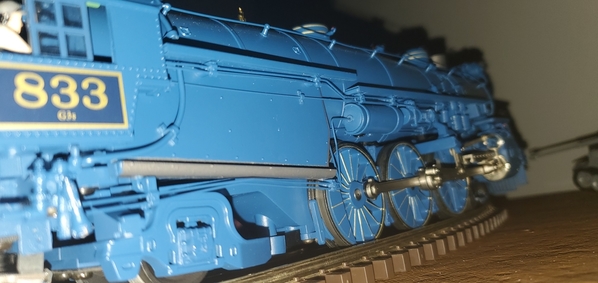

I have the MTH 4-6-2 Blue Comet a P47 Baldwin. She has been running like a champ since getting the board replaced however a brand new issue has appeared. On my layout I have a basic oval with 2 atlas o-54 switches before the o-54 curve to the oval. The engine had no issues previously but yesterday while running the engine I had noticed the rear truck hopping and various points on both o-54 switches on either side of the layout. Sometimes the truck will right itself and let the train continue down the track. Other times it will derail the rear drive wheels. Nothing about my layout has changed which is why i am perplexed as to why this is happening now. I have a couple of diesel locomotives that can go through all of my atlas o-54 switches without issues at any speed but the steamer can only pass through at 5 scale mph about 80% of the time without the rear truck lifting.

Furthermore I set up the same problem switches and extended them with straight track to see if the steamer would pass without any issues and it does. I wasn't able to test it at any speed however due to limited space. I still think it may be an issue with the rear truck not fully resetting but i am at a loss. Any insight or experience would be greatly appreciated!

[Update]

A new development, I reversed the engine in the direction of the switch it normally travels (clockwise instead of the usual counterclockwise) and the rear trailing truck on the engine clears both switches on the loop with no problems. Noticing this I flipped the engine around in the opposite direction and ran her and again no issues other than a hop on a rail joiner because atlas doesn't T the frog portion of their switches so I removed that joiner and the hop is gone. However the rear truck still derails in the forward direction (counterclockwise) during operation.

[Update]

I think Ive narrowed down the issue. On the atlas switches they use plastic tabs to attach to the arm that pivots. The rear truck somehow catches the inside tab (the side on the inside of the oval) and that's whats causing it to "hop". At least that's what I believe I am observing now running it in the regular direction again but it doesn't happen in the reverse direction. I am still puzzled.

[Update]

I beleive have a good understanding as to whats going on. From the way I see it the engine goes around the turn just fine but the trailing truck is pushed to the end of its slot in the chassis. When the engine comes to the switch the flange on the trailing truck catches the plastic tabs used to actually throw the switch causing it to "hop" which in turn derails the locomotive. The question is how do I fix the trailing truck so it properly resets itself once the locomotive comes out of a turn onto a straight away?

[Update Issue Found but not fixed]

I have deduced that it is the trailing truck not returning to center after the engine comes out of a turn. My question is how do I correct this? The ground wire doesn't impede movement of the truck but the truck does not move in the slot that the rod with the spring combination sit in after a turn. Would more weight on the truck fix this?

As always your help is greatly appreciated!