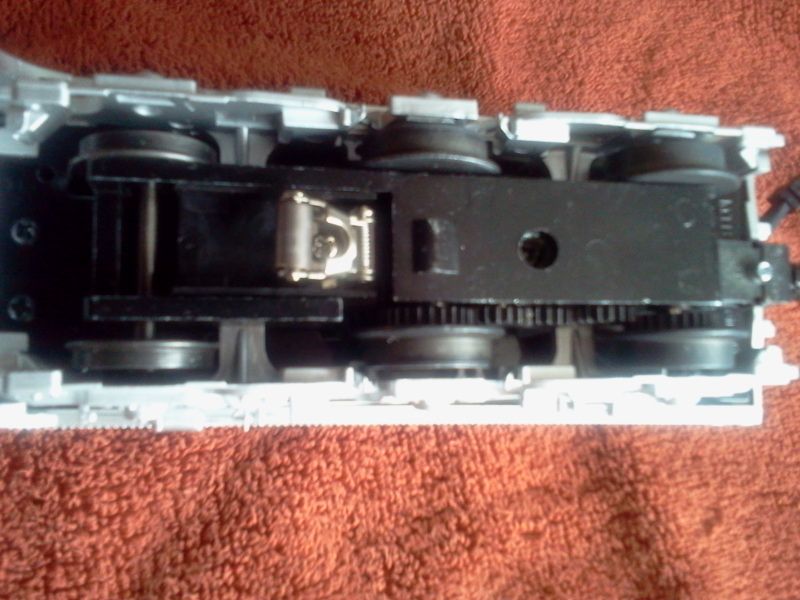

It has been a while, but I routinely replace axle gears on this identical truck block, albeit with scale wheels. Most of the Museum locomotives came from MTH with scale wheels.

I have two-railed a bunch of K-Line Train Masters, both with and without the NWSL kit. Never had any real problems with that. The MTH press- fit, when not involving an insulated axle, is quite tough. But plastic wheels ought to be trivial.

First, if all you are doing is replacing that end blind set, consider finding a Hi- Rail wheelset that matches the other two. Using a scale wheel in that slot is probably going to lead to more problems, not fewer. The larger flanges will aid in tracking, and the extra weight will help almost as much.

You are correct - the axle gear is pressed on at assembly. I have special spacers that enable me to press the new gear on dead-center, prior to re-installing the wheel I pull off for gear replacement.

So: First, find a vise and a couple pieces of steel to support that wheel from behind. Support the opposite end of the truck block on a wood scrap, so you have your hands free. Tap the axle dead-center with a nail set - it will drop out easily if the wheel is plastic.

Do the same with your new Hi Rail wheel set. Just remove one wheel. Slip it in the slot, and re-press. Better to use a drill press - you can feel it better while pressing, and it will press straighter.