Hi MTH experts! I got my hands on a nice J1E premiere on ebay for what I think was a pretty good deal, but it has some issues.

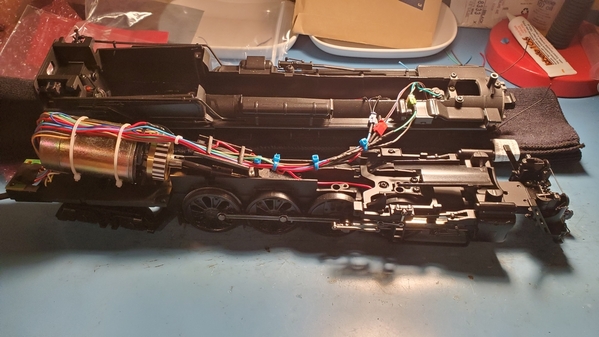

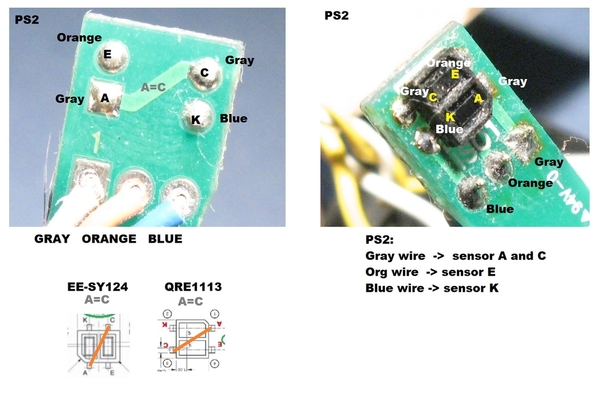

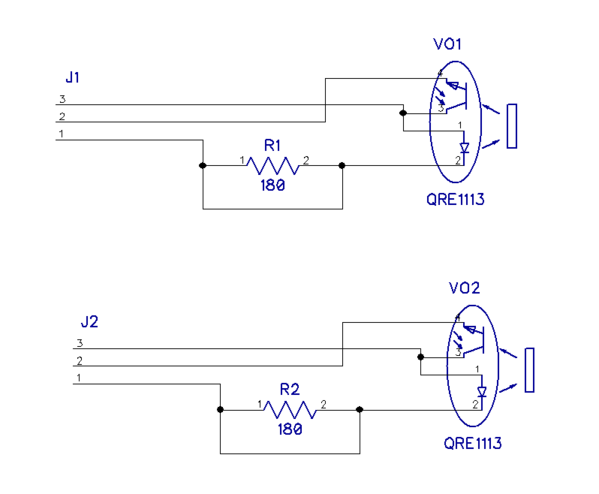

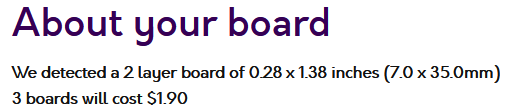

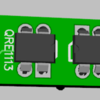

The seller said it was upgraded to either ps2 or ps3. I cant tell the difference between ps2 and ps3 as I'm not familiar with mth's boards. Perhaps someone will be able to tell me based on the photos.

Either way, the engine registers to my dcs explorer but when I try to move forward at slowest setting it quickly picks up speed.... no a jack rabbit start, but it doesnt crawl, and speed builds to the point where its flying off the track almost. when I move the speed back to zero, it lurches to a stop.

Additionally, I'm not getting any chuff.

The smoke unit also runs at constant fan. it does not puff like ps3 or ps2.

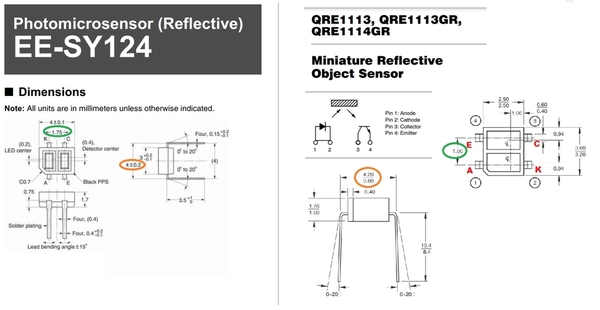

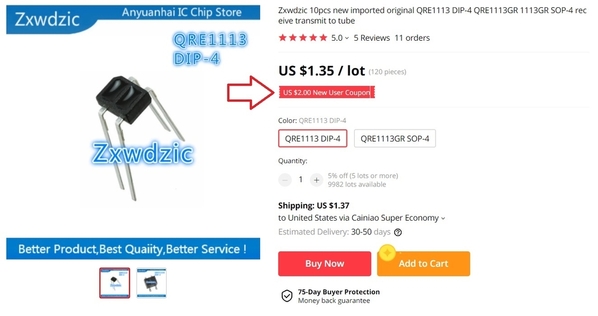

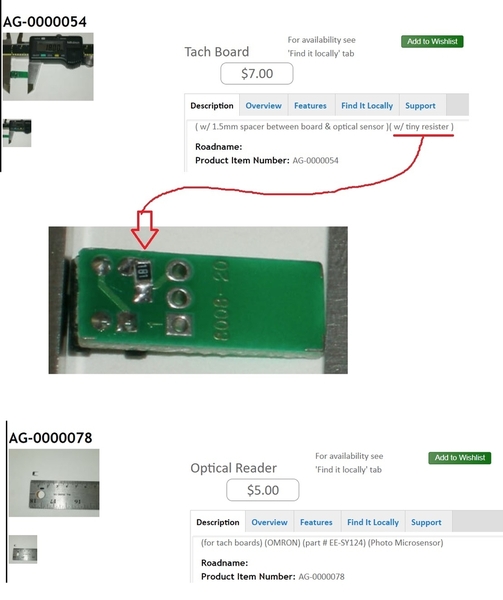

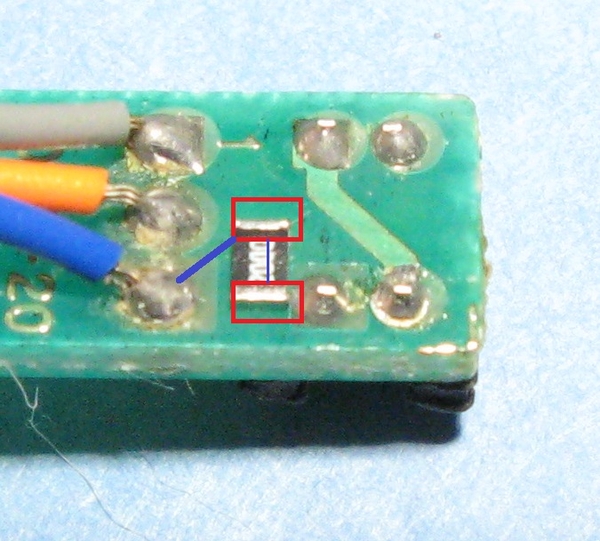

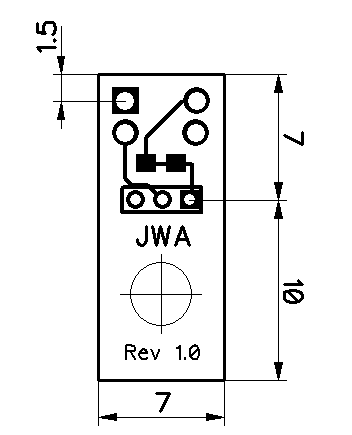

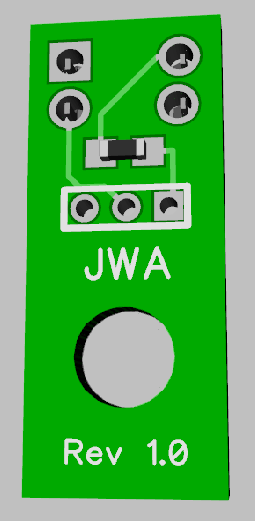

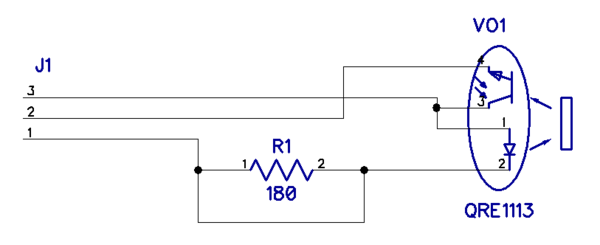

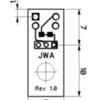

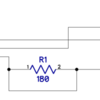

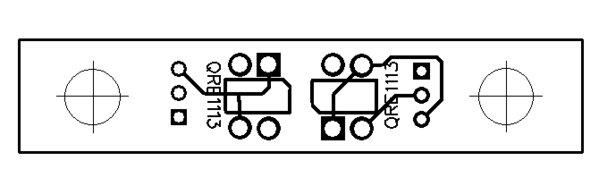

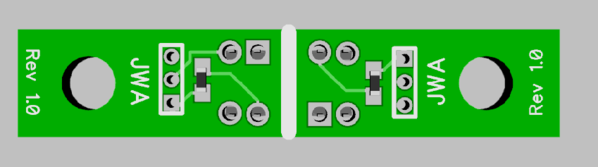

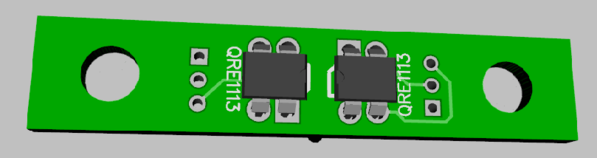

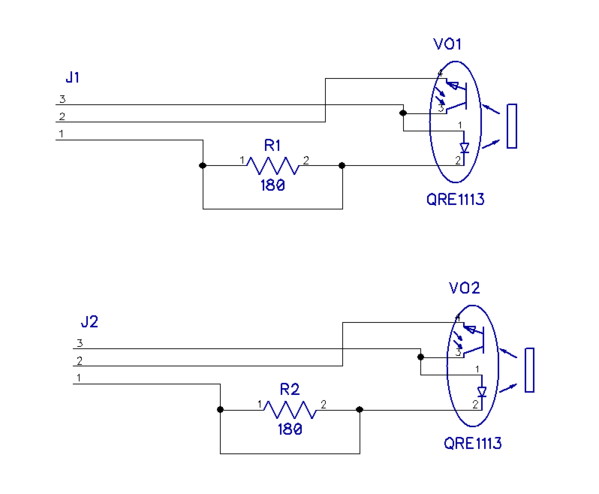

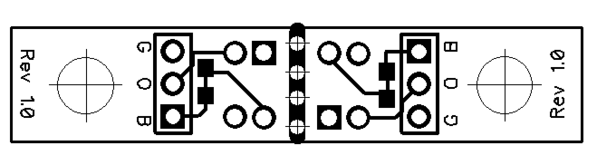

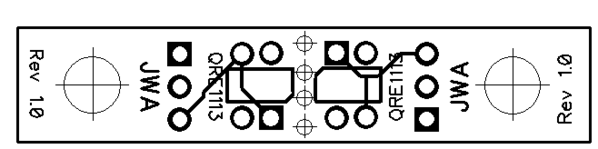

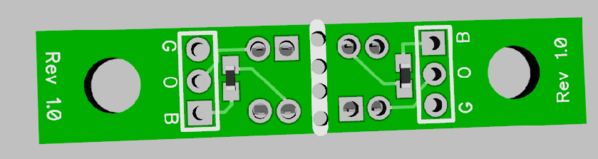

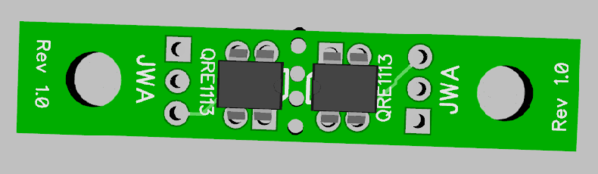

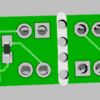

Based on these things I figured it might be related to the tach board or the sticker on the flywheel.... but I couldn't see anything obvious. At a glance it seems to be wired correctly. I tried moving it around several times, cleaning it, looking over the wiring best i could for nicks or cuts..... so far no success. What might I be missing??

I've included a bunch of photos.

Thank to anyone who can help me out!!!