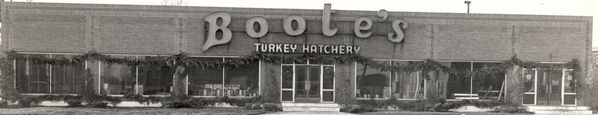

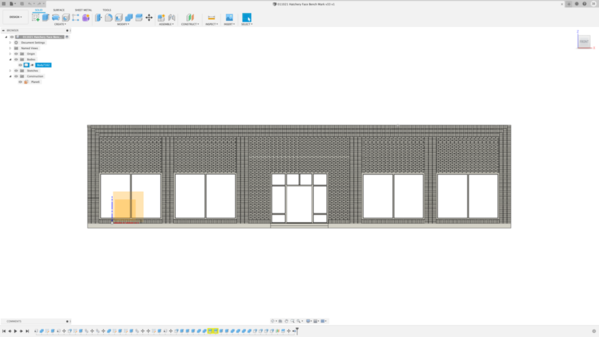

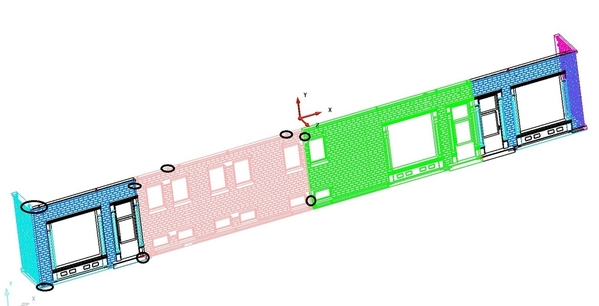

Got a 3D printer for Christmas, Ender 3 v2, so I am trying to create a model of the old family business from the forties. I have several of the Atlas and MTH forty foot refer cars and my old Lionel Scout Loco. I'm trying to create the main building, the old main building burned down which is why there are two different ones, from the building group. The main building is a much too large when scaled to O gauge to fit my grandsons layout so I had to trim the building a bit.

My questions for the forum are;

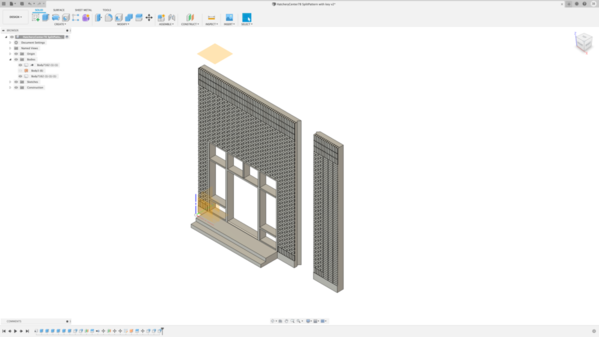

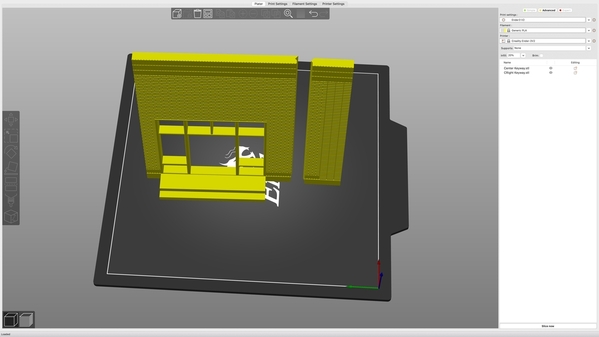

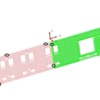

1. I have the front facade done and now am ready to start printing, I Think. I have designed what I think would be a good joint for splitting the front but would like to verify this with someone a bit more experienced. The building is a bit over twenty five inches so I'm thinking four or five sections will be required for printing.

2. What would be the best method to glue the sections back together and best hide the seams?

3. The wall is .3 inch thick but I'm thinking I will probably still need to stiffen it up a bit.

4. The bricks on the face are three different colors, Tan, Reddish, and a deeper red. Suggestions on how to accomplish the painting a decorating.

Any and all suggestion would be greatly appreciated.

.

.