At face value it seems like such a simple and low-cost circuit. But start adding twists and turns and it reminds me of peeling layers of an onion - it will bring tears to your eyes! So doing an OGR search, there have been many threads about this circuit...such as this one.

In the linked post, the beefier 2N3055 NPN transistor is proposed in place of the S8050. Now here's where it gets tedious. For a quick back-of-envelope calculation, a typical transistor might have a current gain of, say, 100. So if you're trying to switch 1 Amp in the transistor output, you need at least 0.01 Amps (10 mA) at the transistor input. In your existing schematic you have a 100K resistor at the transistor input. In addition to charging the capacitor for the cycling function, this resistor must also supply the current to the transistor B (base) input pin. If you only have 12V DC to start with, going thru a 100K resistor can supply at most 12V/100K = 0.12 mA which is woefully inadequate if you want that transistor switching 1 Amp.

So the idea of separating the circuit into the cycling/alternating portion from the buffering portion (to drive the 1 Amp bulbs) is a good one. But to be clear, is the objective to use the OSH Park board you ordered as the cycling circuit...and then the question is how to buffer the board output for a one-off higher power version?

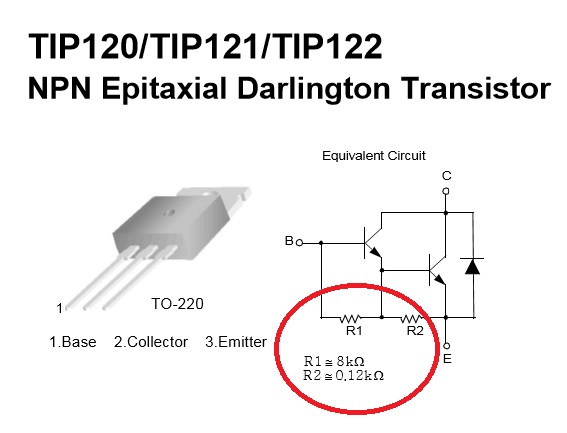

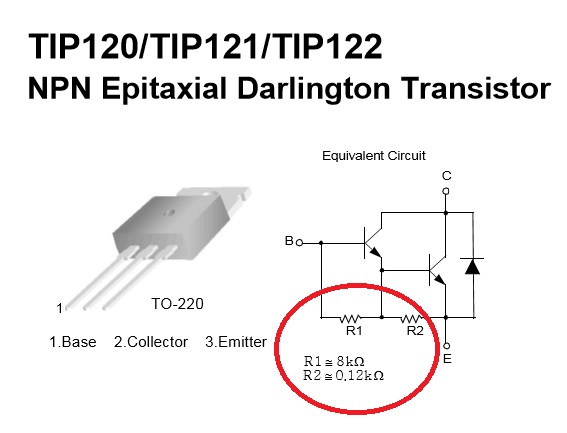

How important is it to use the TIP120? This is a so-called Darlington NPN transistor which has much higher current gain than a normal transistor so might be applicable. But is tricky to apply directly in place of the S8050 because of internal resistors that are small (and hence will "overwhelm") compared to your 100K external timing resistor. This would mess up the capacitor charging. There are ways around this but more layers of the onion!