Hello everyone, I'm new to the forum - thought I might find the help I need here.

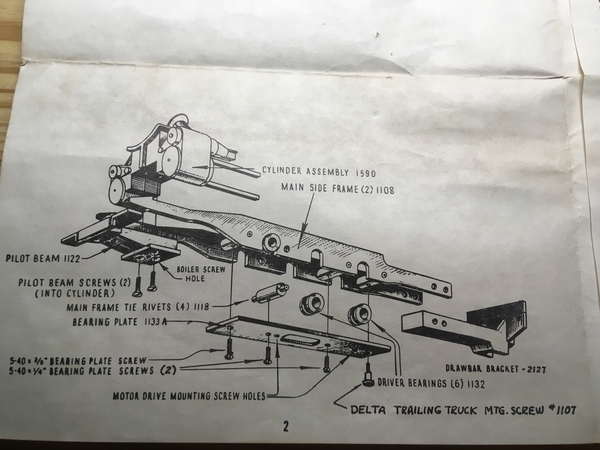

I've recently started assembling a vintage General Models Corporation Pacific, which uses the same mechanism as the All-Nation locomotives. So, here's my problem... When I try to install the "bearing plate" (the plate that mounts underneath the frame and retains the drivers), the second and third drivers begin to bind up. This is just with the screws finger tight. Is there a known solution to this?