Thanks for the input Dave as well as a vote of confidence.

Ok, my turn. I get it programmed everything works as it should forward, reverse, smoke whistle, bell couplers. We're batting 1000.

BTW, I pulled up at the front of the coal bin and it came off without much effort. The magnets are strong, and that's a good thing so it doesn't fall off every time the tender isn't upright. All in all, it's a slick design.

I run it down the siding where it crosses 2 fastrack turnouts. At the second turn out it jumps and shorts out.

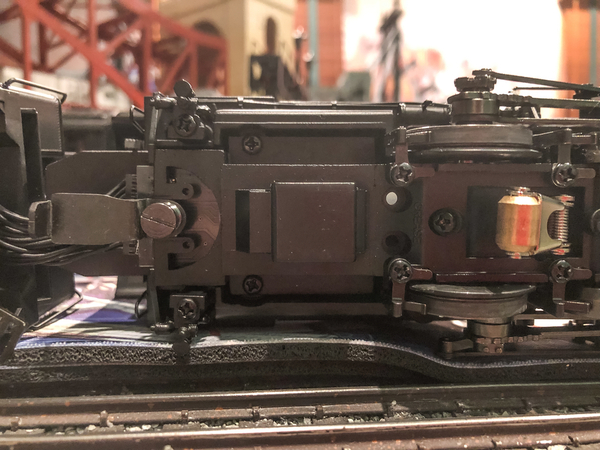

The front pickup roller is loose. O.k. no biggie just tighten it up. Uh oh, won't tighten, screw bottoms out and the pickup is still loose. It falls off taking a double sided nut with it.

I really don't want to send this thing back. I'm no expert but I've had all of my engines open at one time or another for routine smoke unit maintenance.

The double sided nut ties the pickup roller to the hot wire/screw. Apparently the hot wire screw was never sufficiently tightened.

I took the 3 of the gearbox cover screws out, loosened the last, so I could rotate the cover and get the board and wiring out of the way and tighten the pickup wire onto the nut and snug up the pickup at the same time.

Problem solved.

Now the good and bad. Overall it's a great looking model. No suprise, the loco is Mth tooling. The tender Lionels respectable usra tender for 2 decades.

However, this model reminds me of the H10. It must be the same contractor as the casting is rough in the steamchest/pipe area and there are faint parting lines across the top. The handrails are unpainted , but that's 10 minutes with a brush. It does have a whistle cord, cab glass and a nice looking backhead. None of which are on the h10 at about the same price point and this 0-6-0 is more accurate to the prototype.

On the layout these flaws aren't noticeable. I can see similar in Skips as well as Mr. Muffins so I think the odds of getting a "perfect one" are slim.

The tether never really feels "seated" but it doesn't fall out. I suspect this is to make it easier to disconnect without damage. I put my thumbs in front of the cab and reached around and under the deck plate using my second finger nail on each hand on each edge of the plug. I was leery about raising the deck plate vertically for fear I might bend it or break the hinges.

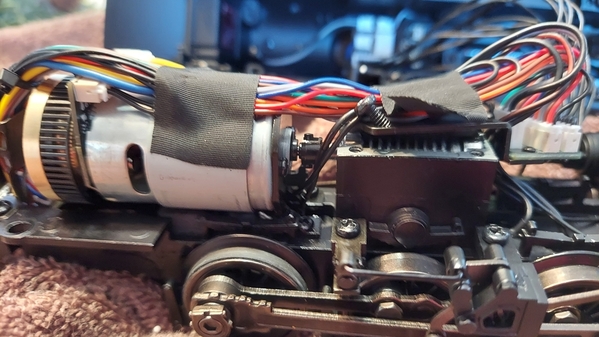

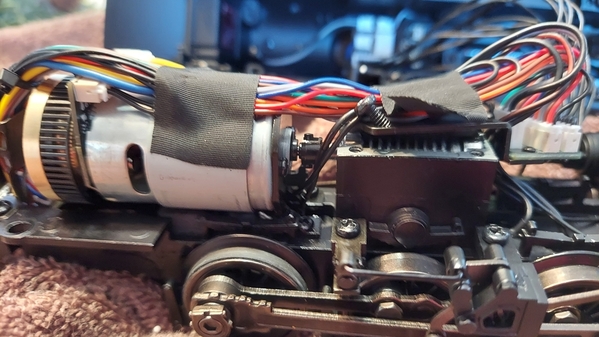

There is a larger horizontally mounted can motor than I would have expected, which is a plus. It does have the multi gear gearbox however Lionel has covers over the outside and I suspect something has been done to prevent the shifting/wear in the K4 and Mikados.

BIG PLUS. The drive line looks like they were taking notes from Pat @harmonyards. A metal driveshaft and the worm turns in ball bearings.

I added some grease. There wasn't a ton of that clear stuff they use at the factory, much of it was liquefied and running down the chassis.

Not the best photo:

Who's to say what the causes of the other failures are but, I would suggest folks that purchase these check the pickup roller tightness out of the box.

Aside from the casting flaws. I do like the loco, so I plan on keeping it unless I run into a huge operating failure. As a switcher, it runs slower than anything I have ever experienced in any scale. The 3rd whistle, Reading style? Really fits this loco.

I only ran it a few minutes. I need to give it a good break in run to make sure there are no more gremlins

Anyone who prefers cosmetic flawlessness may want to pass. We all have different levels of what's acceptable, and that's o.k.

Sorry for the long winded post. Hopefully my findings can help others.