John, there is a Marx-O27 SCARM library, but I couldn't find Marx 1590 switches either. If you can provide detailed measurements of them to SCARM's creator, he may be willing to add them. His name is Milen Peev. He can be contacted via the SCARM blog. He's also a member of this Forum. His user name is Mixy.

All of these design and mechanical issues because someone wants to use Fast Track. Why? Its far more trouble than its worth (and Fast Track is very expensive.)

None of these problems exist if you just use regular tubular track, and a simple metal cutter to cut certain pieces to fit.

There is a reason that folks continue to design and build with tubular track after almost 100 years!

Mannyrock

@Mannyrock posted:All of these design and mechanical issues because someone wants to use Fast Track. Why? Its far more trouble than its worth (and Fast Track is very expensive.)

None of these problems exist if you just use regular tubular track, and a simple metal cutter to cut certain pieces to fit.

There is a reason that folks continue to design and build with tubular track after almost 100 years!

Mannyrock

Simple: Because he has a lot of Fastrack that he just got this past Christmas. They bought it for him because they could assemble it using paper fasteners to hold the sections together and put it behind a dresser. An oval and a figure 8. Now I want to expand it to a 4 x 8 on a foam board because the kid is obsessed with and loves trains so much so this will be a transition. Maybe next year he will sell the Fastrack. Or maybe the Peter Witt Trolley I am going to give him for Christmas can run on Fastrack and his steam train on the tubular.

But I agree with you.

Thanks for all the help. I really appreciate it.

John

@SteveH posted:John, there is a Marx-O27 SCARM library, but I couldn't find Marx 1590 switches either. If you can provide detailed measurements of them to SCARM's creator, he may be willing to add them. His name is Milen Peev. He can be contacted via the SCARM blog. He's also a member of this Forum. His user name is Mixy.

OK. Thanks. I will contact him.

John

Finally got all the parts I need for this layout. The 042 Gargraves Manual Switches had been on backorder, but I received them today. I have a few questions:

1. What is the extra track piece for that came with the switches?

2. I ordered Woodland Scenics roadbed to raise up the Gargaves track and switches to match the height of the Menards O Gauge tubular track and the Fastrack and some foam pins (T-Pins) to hold it down to the 2" foam.

3. The clearances for the switch don't look like the SCARM plan. It looks too close to the Fastrack roadbed.

4. I may use the garage type foam tiles on top of the rigid foam - not sure (would be much quieter). It certainly is quiet on my 027 tubular layout on plywood.

The whole thing will stand vertically behind a door in his room when not in use and on top of his bed when he is using it.

5. The Atlas plastic bumpers seem pretty flimsy for the two dead end spurs. Any way to reinforce them?

6. How would you wire this layout to electrically separate the inner and out loops IF he wanted to run two trains at some point? Turn it on and off. Toggle switch on the center rail at the two outer switches?

Thanks,

John

Attachments

Hi John, please see my comments in Orange below inside the quote box.

- SteveH

@Craftech posted:Finally got all the parts I need for this layout. The 042 Gargraves Manual Switches had been on backorder, but I received them today. I have a few questions:

1. What is the extra track piece for that came with the switches? My guess is that is would be used to extend the Switch's curve length to be equal to a standard GGO42 curve, maybe similar to the extra partial curve pieces included with some FasTrack switches.

2. I ordered Woodland Scenics roadbed to raise up the Gargaves track and switches to match the height of the Menards O Gauge tubular track and the Fastrack and some foam pins (T-Pins) to hold it down to the 2" foam.

3. The clearances for the switch don't look like the SCARM plan. It looks too close to the Fastrack roadbed. The side of the Fastrack transition pieces roadbed could be trimmed to provide clearance for the GG straight.

4. I may use the garage type foam tiles on top of the rigid foam - not sure (would be much quieter). It certainly is quiet on my 027 tubular layout on plywood.

The whole thing will stand vertically behind a door in his room when not in use and on top of his bed when he is using it.

5. The Atlas plastic bumpers seem pretty flimsy for the two dead end spurs. Any way to reinforce them?

6. How would you wire this layout to electrically separate the inner and out loops IF he wanted to run two trains at some point? Turn it on and off. Toggle switch on the center rail at the two outer switches? After cutting the center rail to provide electrical isolation between the loops, there would be many options for powering the loops independently, including toggle switch(es). You might also want to isolate the spurs. An economical and compact solution for utilizing two independent power supplies (transformer channels) would be the Atlas#215 Selector. It will control up to four independent tracks (loops and spurs) and allow either power source to control each track. For each track, each of the 4 switches can be set to select Source A, Off, or B. If you decide you want to control more than 4 tracks, the #215's can be daisy chained side by side with the included hardware.

Thanks Steve,

I posted another thread in the 3 rail forum asking about Gargraves switches. They don't seem to be widely used very much.

1. I'll cut the corner off the Fastrack roadbed to allow for the Gargraves switch and transition track to clear

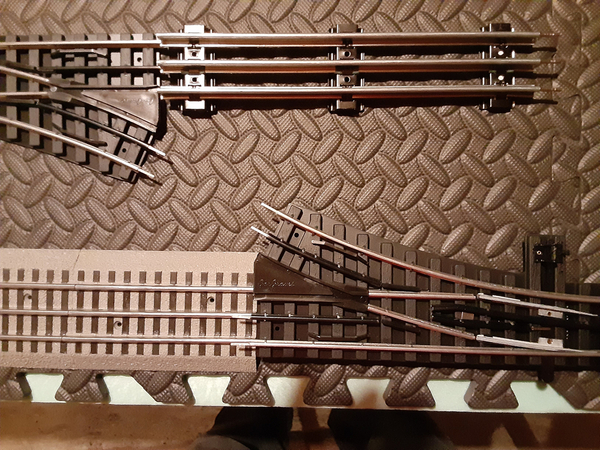

2. Also, what do I do with the plastic section of the switch that are missing pins. You can see them in the photo. They aren't on the 0-54 switch. Those have metal track ends with pins. All the 0-46 switches have a triangular plastic corner with a pin missing. Nothing on their website explains what to do with that.

3. Let me see if I understand how to isolate the inner and outer loops.

A. Cut the center rail of the two Gargraves transition pieces at the loop exits.

B. Wire all three center rails together on the switches (as with all Gargraves switches)

C. Attach a wire to each half of the cut center rail on the transition piece and attach them to a toggle or slide switch.

D. Or use the Atlas #215 selector. I looked up a photo of that and I already have one in the basement that was intended for my N Gauge, but never used. I assume it works for O Gauge as well.

E. No plastic insulator pins are needed anywhere on the layout.

Truly appreciate the endless help you provide for members of the forum Steve.

John

John, please see my comments in Orange below inside the quote box.

@Craftech posted:Thanks Steve,

I posted another thread in the 3 rail forum asking about Gargraves switches. They don't seem to be widely used very much.

1. I'll cut the corner off the Fastrack roadbed to allow for the Gargraves switch and transition track to clear

2. Also, what do I do with the plastic section of the switch that are missing pins. You can see them in the photo. They aren't on the 0-54 switch. Those have metal track ends with pins. All the 0-46 switches have a triangular plastic corner with a pin missing. Nothing on their website explains what to do with that.

My only O gauge track real world experience with is with Lionel FasTrack and Tubular. My guess would be that if there is no place in the O54 GG switch frog for track pins, that one might only use the provided pins for the necessary electrical connections and the frog would be electrically isolated. If the track is secured to the base, the remaining two steel pins should provide enough physical strength to keep the joined track aligned.

3. Let me see if I understand how to isolate the inner and outer loops.

A. Cut the center rail of the two Gargraves transition pieces at the loop exits. Either that or it may be possible to use Fibre pins to create center rail isolation between one of the switches and the short GG straight if the GG switches will accept them. But, since the center pin connection would be providing one of only two physical alignment forces between the divergent end of the crossover switches and the straight track in between them while mounted on a somewhat flexible base, using all steel pins and cutting the center rail on the straight instead may make the physical track connections more solid.

B. Wire all three center rails together on the switches (as with all Gargraves switches) I think that is correct.

C. Attach a wire to each half of the cut center rail on the transition piece and attach them to a toggle or slide switch. Maybe. However, the center rail power to each loop could be connected anywhere on the loop (if not using DCS) and preferably in two or more places, but it doesn't necessarily have to be near the center rail break between the loop crossover switches since the power will run through them as discussed above in 3B.

D. Or use the Atlas #215 selector. I looked up a photo of that and I already have one in the basement that was intended for my N Gauge, but never used. I assume it works for O Gauge as well. Even thought Atlas markets similar selectors (more expensive with less switching options) specifically for O gauge, I can attest that I have used 2 of the #215s for twelve years while running two dual motor (O gauge) diesels simultaneously pulling 15-20 car loads with no problems all from the same power source. I would guess that load to be about 6-8 amps. The "O gauge" Atlas selectors likely have a higher current rating than the #215.

E. No plastic insulator pins are needed anywhere on the layout. If you decide to independently wire the spurs as isolated blocks, insulating pins might be used instead of cutting the center rail near the switches.

Truly appreciate the endless help you provide for members of the forum Steve. Thank you, Steve H

John

Maybe the plastic sections on the O-42 track are wheel guides because the O-42 turn is sharper than their other switches? I'll try calling Gargraves tomorrow and ask them. If I can reach them I will post their answer here.

=========================================================================

I looked in the basement and I actually have three different Atlas slide switch controls. Blew the dust off of them and two say Atlas Connector and one says Atlas Selector (The one hat looks exactly like the #215). It's actually pretty heavy for what it is. Lots of options. Thanks for the suggestion or I would never have thought about those.

=========================================================================

"using all steel pins and cutting the center rail on the straight instead may make the physical track connections more solid."

I will have extra Gargraves regular track so I think this may be the best option to try.

==========================================================================

If you decide to independently wire the spurs as isolated blocks, insulating pins might be used instead of cutting the center rail near the switches.

Since the spurs are tubular that makes perfect sense.

==========================================================================

C. Attach a wire to each half of the cut center rail on the transition piece and attach them to a toggle or slide switch. Maybe. However, the center rail power to each loop could be connected anywhere on the loop (if not using DCS) and preferably in two or more places, but it doesn't necessarily have to be near the center rail break between the loop crossover switches since the power will run through them as discussed above in 3B.

He has a LionChief Plus set with constant track power and a bluetooth remote control. Uses tubular connector track for power brick. It was a Starter set he got last Christmas.

He is getting a Peter Witt Trolley this Christmas with an conventional MRC AC Transformer. He won't be getting the roadway pictured, but instead will probably run the trolley on the inside loop (for now). I purchased a Fastrack power track with connectors for a conventional transformer if he wants to use a conventional transformer on the layout. I made him an adapter for the MRC conventional transformer that has screw terminal connectors on one end and the tubular connector for the tubular Fastrack power track on the other.

Can a five year old (even with supervision) keep it all straight? I don't know, but if he is told not to mess with the slide switches he won't.

John

@Craftech posted:.. Can a five year old (even with supervision) keep it all straight? I don't know, but if he is told not to mess with the slide switches he won't.John

Connor sounds like a bright young fellow. If he doesn't completely understand the full capabilities of the #215 at first, I expect he soon would.

@SteveH posted:Connor sounds like a bright young fellow. If he doesn't completely understand the full capabilities of the #215 at first, I expect he soon would.

Thanks for that Steve. I really appreciate it

John