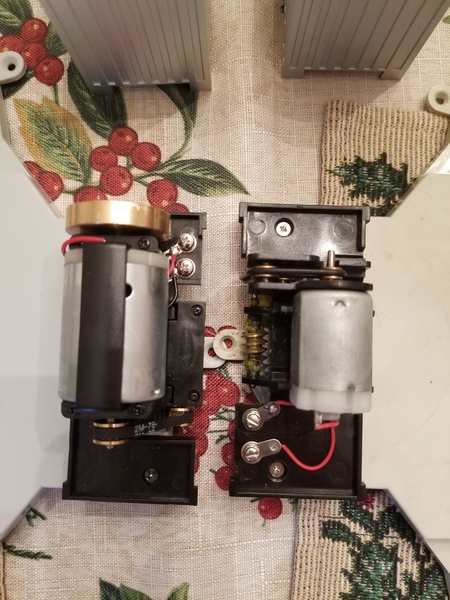

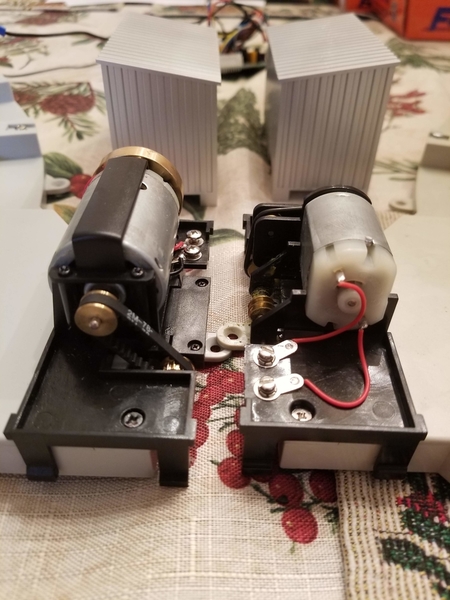

I just received my new Atlas turntable yesterday. I haven't had a chance to run it yet but I took a couple of pictures to share with the group. From the first picture you can see that visually its the same turntable that was issued before. In the second picture you can see the larger can motor which includes a flywheel, the belt was also made larger and flat. They said they beefed up the deck with more rollers but I'm inclined to not take the top off for fear of a jack in the box setup like the previous one.

Replies sorted oldest to newest

Looks like a very big improvement.

I ordered one which should be in this week. I'll let you know what I think after install.

I've got an original that I ordered after seeing the prototype at York many years ago and I think it's the best postwar-style accessory that Lionel never made. I use mine with the manual crank, is that still an option?

This turntable is made by Atlas, however the manual crank is still included with it.

Davety: I know Atlas made it, I own it. Read it again.

I hope the rollers under the table are improved because the original type were undersized and junk. The one I had would not even rotate under the weight of the engine.

If so I might be inclined to buy one.

artyoung posted:Davety: I know Atlas made it, I own it. Read it again.

Ok, it's hard to see what you're getting at with your statement. Perhaps worded differently would be less confusing. Since this is not a post-war accessory (it's modern) and Lionel hasn't made their turntable since 1964, over 50 years ago. You might understand why I saw it that way.

Freight Train Jim posted:I hope the rollers under the table are improved because the original type were undersized and junk. The one I had would not even rotate under the weight of the engine.

If so I might be inclined to buy one.

From their website:

• New - larger and more powerful motor

• New - flat cogged anti-slip belt

• New - deck support with more roller bearings for greater support

of heavier locomotives

• New - redesigned metal contacts to power the rotating track

Certainly looks like they improved the product.

The obvious advantage to me is the ease of installation. However it has nowhere near the detail of pit type turntables. Does this product also have a smaller footprint than those available from other sources?

Paul

Railrunnin posted:Certainly looks like they improved the product.

The obvious advantage to me is the ease of installation. However it has nowhere near the detail of pit type turntables. Does this product also have a smaller footprint than those available from other sources?

Paul

Its takes up 26" and the turn part of the table is 24".

What's the price of this new turntable and who has them?

$299.99 msrp. I bought direct, I'm sure some dealers will have them.

I have an unopened one from many years ago that I plan to use. I wonder if I can get the new parts to upgrade it? Looks like another email to Atlas.

Wow! They really have made some much needed improvements. I had to totally change out the motor and drive system on my old Atlas turn table. The rubber band drive was terrible.

Just last week, Atlas put out this video about their new turntable. On their YouTube channel.

I was impressed....

https://www.youtube.com/watch?v=TaOeToIjEJo

Check it out: Gary

Is the house that covers the motor the same size as the original? I wonder if the new motor/belt drive can be retro-fitted to the older TT?

If not, I have a box full of motors and might see if I can DIY.

Yes, the shed is the same size on both.

Davety posted:artyoung posted:Davety: I know Atlas made it, I own it. Read it again.

Ok, it's hard to see what you're getting at with your statement. Perhaps worded differently would be less confusing. Since this is not a post-war accessory (it's modern) and Lionel hasn't made their turntable since 1964, over 50 years ago. You might understand why I saw it that way.

perhaps this will help - the word never is the key - "that Lionel never made"

Moonman posted:Davety posted:artyoung posted:Davety: I know Atlas made it, I own it. Read it again.

Ok, it's hard to see what you're getting at with your statement. Perhaps worded differently would be less confusing. Since this is not a post-war accessory (it's modern) and Lionel hasn't made their turntable since 1964, over 50 years ago. You might understand why I saw it that way.

perhaps this will help - the word never is the key - "that Lionel never made"

I saw that, it's word trickery and it's supposed to be confusing. People only use it to try and look smart.

This thread is starting to get off topic. Lets try and keep the posts on topic about the new Atlas turntable please.

Davety posted:Freight Train Jim posted:I hope the rollers under the table are improved because the original type were undersized and junk. The one I had would not even rotate under the weight of the engine.

If so I might be inclined to buy one.

From their website:

• New - larger and more powerful motor

• New - flat cogged anti-slip belt

• New - deck support with more roller bearings for greater support

of heavier locomotives

• New - redesigned metal contacts to power the rotating track

I really never did have much of a problem with it's flimsy drive system. The biggest issue has always been something I've never been able to remedy, the table bed having intermittent or weak electrical contact with the engines causing erratic shutdowns, DCS engines being especially problematic or unable to receive signal. If this new replacement cured those problem and its a drop in utilizing all existing wiring, I may go for it...

joe

Davety, Thanks for starting this topic. Hope you will give us full report on setup and how it works.

I have the older model and it worked fine once I replaced the rubber band drive with an O ring suggested here on the forum. All went well until I "weathered" it. I got some of the "weathering" under the table and in the mechanics...I can still manually turn it, but lost the gears etc. !! Lesson learned. I am considering getting the new improved model. Looking forward to your updates. I have even figured out a way to "weather" it this time without goofing the whole thing up.![]()

Does it take up the same space as old table?

Thanks,

Tom

Tom Q Fan posted:Davety, Thanks for starting this topic. Hope you will give us full report on setup and how it works.

I have the older model and it worked fine once I replaced the rubber band drive with an O ring suggested here on the forum. All went well until I "weathered" it. I got some of the "weathering" under the table and in the mechanics...I can still manually turn it, but lost the gears etc. !! Lesson learned. I am considering getting the new improved model. Looking forward to your updates. I have even figured out a way to "weather" it this time without goofing the whole thing up.

Does it take up the same space as old table?

Thanks,

Tom

Yes, it takes up the same space as the old one. I plan on it installing this weekend if time permits. I'm going to the show in Timonium this weekend so that will eat up some of my time. I have to rewire my whisker tracks as I've added to them and my LCS PBC2 is full so I'm adding a 2nd one. That will take time as well. I'll try and post some updates once I get some of the work completed.

If only I didn't have those articulateds, I would have bough an Atlas TT - of course, it would have been the old one back then, and I guess that they were fairly flawed.

Anyway, "moving deck" and all, I'd use it if possible. But, it's not.

(There were TT's here and there with decking that turned with the TT bridge, but it was the exception. Painting the entire deck and faux "bridge support track" flat black would help disguise it.)

Since the turntable is surface mounted, does any one know how it matches up (height wise) with various trackage, especially Fastrack, and if any shimming is required ?

Richie C. posted:Since the turntable is surface mounted, does any one know how it matches up (height wise) with various trackage, especially Fastrack, and if any shimming is required ?

I use Fastrack on my layout and had to use shims to get it to meet up. I didn't measure the distance that I needed to shim. I was fortunate enough to work a stint at a data center where they were throwing away hundreds of these. I didn't count how many I got, It's in the hundreds if not the thousands. I use them as shims all over my layout including on the tracks up to the turntable.

Attachments

You can always build up the area around the TT with foam and set the TT down inside a cut out circle. Of course, some of the track(s) around the TT might be on an incline but it's not like you'd be pulling a train, just the engine. I did this with my anti-fatigue matting, but it's only 3/8" thick:

Attachments

Mine arrives tomorrow!

I orderd mine yesterday from Legacy Trains and the price was $269.99. I have the older atlas table but too many problems especilly with the drive system. Also does any one know how to connect the table with fast track? Thanks.

Choochoo Bob, I attached Fastrack to mine, you can see picture above. Just have to notch it and fits nice. Might need a very thin shim, depending on your layout base.

-Tom

I built my own

If you are looking to buy, you will not find a better price than at M.B. Klein. Add it to the cart and be amazed. You can empty the cart after looking.

Charlie

Better price is at Charles Ro. Received mine yesterday.

Yes, but out-of-stock.

Just order mine from modeltrainstuff.com. Good price.

I was close to installing the older model when I read this post; ordered the new one immediately.

Got mine $209 from Charles Ro preorder, and $9 shipping.

Just got mine yesterday from Modeltrainstuff, M.B.Klein.

How can a new improved turntable only cost $209.00; it just not right. How can Atlas make any money on this

daylight posted:How can a new improved turntable only cost $209.00; it just not right. How can Atlas make any money on this

while I can't speak for Atlas, some assumptions can be made. This is the same molding as their previous run, so they didn't have to pay for R&D or new molding. That right there saves them a ton of money.

Guys, please update here on how you like the new turntable and setting it up. Is anyone swapping out the new for the old? I still have the old one and considering getting the new one. I am hoping the wiring could stay where it is and just swap out the new for old.

-Tom

I am replacing the original model with the new one. The old model did not work well with my scale engines(weight issue). It will be a while before I install the new one as am using old one to work out track solution with a new roundhouse I recently built from a kit. The two earlier roundhouses, a 3-stall Atlas and a 5-stall Scale University, were just too big for the space available. The new roundhouse is a Korber 3-stall and appears to be an old, out-of-production model. I could go on infinitum about my difficulties assembling that sucker, but will refrain. Will post results on the turntable when/if I get it operational.

I finally was able to get enough time to install the new table. I took a video of the old and then the new table in action. The first video is the old table so you can get a comparison of each, at the end of the video I run it at full speed. The 2nd and 3rd video are of the new table, I meant to pause the video when a short occurred but stopped it instead thus splitting it in two. I think the short was cause because my table is just sitting on top not secured and I'm having a shimming issue, that was the case after the installed the first table and was resolved once shimmed. I noticed that the indexing for the new table is different. On the old one there is a longer pause at each stop. This made it a little bit harder for me to use and get the new table to stop where I wanted it to. I'm sure I'll get used to that over time. I also got pictures of the two tables side by side. The old table is slightly yellow compared to the new more grayish one. I don't smoke and believe this may be a result of the plastic aging, like that old computer monitor that everyone has had that turned yellow at the end of it's life. Something important to note is that the power connections are switched on each of my tables. One the old one the common was to the left of the motor, on the new one it's on the right. Also the motor power connections are switched as well. I'm using the ERR mini commander with mine. when I start the table in what would be forward I like it to turn clockwise, and reverse counter clockwise. Connecting the wires to the opposite connectors did that. Also the ERR board did not fit under the new shed,Which is the exact same size as the old shed. I was able to install mine in a TMCC direct lockon building I had that had no electronics already in it, which you can see in the 2nd and 3rd videos just to the left of the motor shed.

Old Table

New table 1

New table 2

This is a close up of the gearing. I was working the flywheel a little bit back and forth to show that the gears moves a little bit left and right. I hope this doesn't cause any issues.

Attachments

Davety, many thanks for taking the time to video and upload them here. That helps me make my decision. I will replace mine with the new turntable in the coming weeks. You did great job with you Fastrack and connecting to the turntable.

-Tom

Does the Lionel PH 180 and CW 80 need a rectifier on a Atlas turntable?

Stephen G posted:Does the Lionel PH 180 and CW 80 need a rectifier on a Atlas turntable?

Yes. Both the old and new table include a bridge rectifier. The new table bridge rectifier has a switch on it. I tested my table using a CW-80.

Attachments

Tom Q Fan posted:

Hello. Thanks for your pics. I am working on installing one now. Did you use a ‘transition track piece at the end or did you cut off a regular section?

Hey Ronald, I can't speak for Tom, but on my layout I did use a Fastrack 5" transition, and simply pulled the tubular pins out, then cut back the road bed as Tom did.

Ronald, I did as David did. Used transition piece, pulled pins and notched it out. I used Gargraves inside.

-Tom

Tom Q Fan posted:Ronald, I did as David did. Used transition piece, pulled pins and notched it out. I used Gargraves inside.

-Tom

And for those following along: this method works for many of the classic Lionel accessories as well where Fastrack meets up with built in tubular; the classic Coal Ramp, as an example.

Does this new turntable match up with Lionel O gauge tubular track?

ok - stupid question of the day - why did you use a 5" transition piece instead of just notching out a regular 4.5, 5 or 10 inch piece of FT ?

Was it just for the ease of being able to pull the mating pins out rather than having to disconnect and lift the rails and remove the FT pins ?

EscapeRocks posted:Tom Q Fan posted:Ronald, I did as David did. Used transition piece, pulled pins and notched it out. I used Gargraves inside.

-Tom

And for those following along: this method works for many of the classic Lionel accessories as well where Fastrack meets up with built in tubular; the classic Coal Ramp, as an example.

And o22 turnouts

Richie C. posted:ok - stupid question of the day - why did you use a 5" transition piece instead of just notching out a regular 4.5, 5 or 10 inch piece of FT ?

Was it just for the ease of being able to pull the mating pins out rather than having to disconnect and lift the rails and remove the FT pins ?

The main reason I used the transition piece was because the end of the track roadbed has a smooth plastic end that I was able to trim down without having to add some kind of shim for support to mate it up the the spinning part of the table. I did have to shim a little outside the table. I wanted it to be firmly down on the plastic lip of the table. I hope this makes sense.

Attachments

Did someone mention here that the leads for the TRACK portion of the turntable are backwards? I am installing one and it drove me crazy for a while. I followed the instructions and kept shorting when running engine onto it. Swapped wires and it is working fine now. Pretty sure where my wiring is good. Common ground everywhere. Thanks for replying. Ron.

ronald weatherby posted:Did someone mention here that the leads for the TRACK portion of the turntable are backwards? I am installing one and it drove me crazy for a while. I followed the instructions and kept shorting when running engine onto it. Swapped wires and it is working fine now. Pretty sure where my wiring is good. Common ground everywhere. Thanks for replying. Ron.

Yes, in my post from above that has that big block of text. "Something important to note is that the power connections are switched on each of my tables. One the old one the common was to the left of the motor, on the new one it's on the right." Glad you got it figured out.

Davety posted:Richie C. posted:ok - stupid question of the day - why did you use a 5" transition piece instead of just notching out a regular 4.5, 5 or 10 inch piece of FT ?

Was it just for the ease of being able to pull the mating pins out rather than having to disconnect and lift the rails and remove the FT pins ?

The main reason I used the transition piece was because the end of the track roadbed has a smooth plastic end that I was able to trim down without having to add some kind of shim for support to mate it up the the spinning part of the table. I did have to shim a little outside the table. I wanted it to be firmly down on the plastic lip of the table. I hope this makes sense.

That makes perfect sense. I've only used FT transition pieces for my Gargraves gantry track (which had to be shimmed up about 1/4") and didn't notice a difference in the ends. Thanks.

Davety posted:ronald weatherby posted:Did someone mention here that the leads for the TRACK portion of the turntable are backwards? I am installing one and it drove me crazy for a while. I followed the instructions and kept shorting when running engine onto it. Swapped wires and it is working fine now. Pretty sure where my wiring is good. Common ground everywhere. Thanks for replying. Ron.

Yes, in my post from above that has that big block of text. "Something important to note is that the power connections are switched on each of my tables. One the old one the common was to the left of the motor, on the new one it's on the right." Glad you got it figured out.

Yes I see it now. Thanks. I thought age-related issues were taking over.

This is my first go at a turntable / roundhouse combo. I am using Fastrack on my layout. I chose to cut some pieces to fit into the turntable. I am glad I took that approach. They work really smooth.

I am also controlling the turntable motor with a TMCC amc 6-14183. You can set it to send DC current to the motor without having to install the rectifier. Seems to work fine. I can move the motor from the handheld which to me is a great thing.

Thanks again for the reply.

This is a close up of the gearing. I was working the flywheel a little bit back and forth to show that the gears moves a little bit left and right. I hope this doesn't cause any issues.

I don't own one of these turntables, but there is a good possibility I may in the near future. Watching the last video, It seems if one was to shim the worm gear to the center, that would elevate the movement and keep the belt more in line with the motor cog.

Ron and Davety, thanks for mentioning about the leads. I wonder if that is on all of them? When I connected mine I did not notice that anything was backwards. I do have limited knowledge of electronics.

-Tom

Tom,

You would know. Mine was sparking in the gap between the TT and the track. The two motor engine would stall half way in.

I sent an email to Atlas customer service about it. Maybe they will eventually update their instruction sheet.

I’m not an electrical expert but I knew something was amiss.

I really like this forum. Lots of people willing to share info. I don’t feel like I’m in this alone. I have some experience but there’s always something cropping up.

Again, Does this new turntable march up with Lionel O Gauge tubular track???

eddie g posted:Again, Does this new turntable march up with Lionel O Gauge tubular track???

Eddie, I’m using 027 track inside my roundhouse. Works fine. A little shimming where it meets the TT.

Ronald , thanks for your reply. Yes this forum is great. So many people willing to share.

-Tom

I realize this isn't the topic. Can a CW 80 be used to run the Atlas turntable with 4 or 5 legs?

Stephen G posted:I realize this isn't the topic. Can a CW 80 be used to run the Atlas turntable with 4 or 5 legs?

It would depend on the engines you're using. The CW-80 provides 80 Watts, 5 amps. So as long at the table + the engine don't exceed that, then yet you can do that. Back when I was using a CW-80, sometime I had to turn the smoke off to get it to work with the engine and consist that I was running. Depending on the engine you may have to do that with your setup as well. Another thing to consider is you can run the turning part of the table with a different power supply then you run the tracks from. Thus having 2 different power supplies for you table. You many want to have the ability to turn off those 4 or 5 legs when not in use, thus reducing the power required for engines that are just sitting there. Hope this helps.

Old topic reboot! How can I determine if old or new version of turntable? ( saw the improvements listed) Is there a different part # for newer version? Thanks Tom Weaver

This is my second attempt to post a reply. Anyway, the old version is item #6910; new is #6999.

Cheers

Bill, I was thinking the same thing, thanks for the number.

Tom

Am I correct that the old version is #6910 and the new version is #6999?

@RLH posted:Thanks. I just ran into "new old stock" 6910. Glad I didn't mess up and buy it.

I have both of them. The main difference is the larger motor with a flywheel on the newer one. If you can get the old one for a cheaper price than I'd say go for it. But if you can afford the newer one I would suggest that.

All, thanks for the info. I have not replaced my old one yet, but hope to before fall. I am glad the new one is more robust. I rendered mine into manual mode by getting over enthusiastic in weathering it. Some of the "stuff" got underneath and eventually ground it to halt. Otherwise great turntable for the price and looked really neat when I ran it electronically.

Tom

@Davety posted:I have both of them. The main difference is the larger motor with a flywheel on the newer one. If you can get the old one for a cheaper price than I'd say go for it. But if you can afford the newer one I would suggest that.

It was $200 plus shipping. I don't think that is a good price given the new one is $299 MSRP.

Late last year, I bought the new model from an Atlas dealer for $230. At the time, Atlas had them in stock. I don't know what the current situation is.

So reading this it seems a lot of people have had time to test the 6999. Any issues that would prevent you from recommending it now that you have used it for a while?

Joe, thanks for asking. I still haven't gotten around to getting the new one. I have the older one that has become manual. The mechanics on the old one were not that sturdy. Hopefully you will hear some updates here. I still want to get the new one.

Tom

I spent considerable time on smoothing/leveling the layout table surface prior to positioning the TT. All effort for naught. Same problem I had with the earlier model: weight of engine causes the platter to sag which results in derailment. All of my motive power units are scale, but the problem occurred using the lightest engine I have, an 0-8-0 steam switcher. Since there seems to be a number of members here that have had success with the new model, don't be discouraged by my experience. I may not have the right touch to fix the problem.

Bill, what is under your turntable? My layout has 4" of that pink foam, two 2" thick sheets. It has supported all of my engines so far.

Tom

@Joe Rocco posted:So reading this it seems a lot of people have had time to test the 6999. Any issues that would prevent you from recommending it now that you have used it for a while?

Joe, I've been using mine since I created this post. I did have some issues early on but that's because my table was not completely flat. All I had to do was add a few shims here and there to correct that.

I used an old deck of cards as spacers to slide under the frame until it filled gaps. Then I used white glue to immobilize the cards to prevent accidental movement. The overall area is quite level.

@JC642 posted:I really never did have much of a problem with it's flimsy drive system. The biggest issue has always been something I've never been able to remedy, the table bed having intermittent or weak electrical contact with the engines causing erratic shutdowns, DCS engines being especially problematic or unable to receive signal. If this new replacement cured those problem and its a drop in utilizing all existing wiring, I may go for it...

joe

I too had conductivity issues with the old one and especially DCS systems. I was put down by a service tech at my LHS because he was told that my rollers weren’t oiled. They made me feel that I was unhinged for saying that wasn’t the problem.

It’s nice to finally be cured of my mental illness by having it announced that this is a known issue ( for everyone except my LHS).

Several questions for those with experience on the Atlas table:

1) Curved exit track? I had been thinking that the exits had to be straight track but this video shows several 027 curves: https://www.youtube.com/watch?v=S3uvOuUikrE&t=4s What is the experience on the curves that work for a 15-18" locomotive?

2) The atlas controller: the switch part is sensitive and is very easy to miss the pause or push the switch too far and go into reverse. Has anyone tried an alternative?

Thanks in advance for any feedback.

I bench tested the new model and found the indexing to be rather inaccurate. I have a plan to add some electronics, but until the turntable is on the layout, there's no point in talking about my plan. Anyway, my first observation was sloppy indexing.

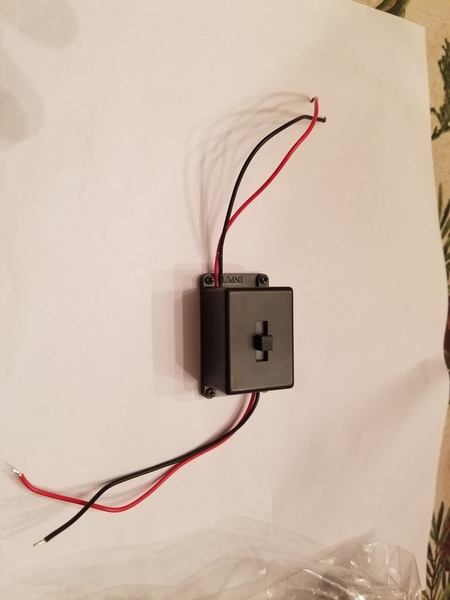

Apparently it indexes with a Geneva mechanism ( go to 2:40 on the video link, nice animation) so it is all mechanical (did I read that in this thread?). Interested to see what you come up with. A minimum is a better 3 position switch! I assume the switch box contains a full wave rectifier?

Just to clarify, I didn't use the Atlas switch box, just a DC power supply with an on/off switch. One gets within a fraction of an inch to the feeder rail you want to stop at, cut power and it may or may not line up. Not what I think indexing should do. It either overshoots or undershoots. If you wait for it to stop moving and cut power, it will overshoot.

I get it and well said. You probably know this already but for anyone else interested, I just looked inside the box:

No wonder the switch is hard to use, not sure we can really call this a switch?

(BTW, the lionchief plus 2.0 is great!)

And it is a rectifier and a capacitor only as far as I can tell.

Attachments

Can a Lionel PH180 be used to power the Atlas Turntable?

As others have said here, Atlas 6999 uses a DC motor. So if you are using a AC power source a rectifier is required. I use the lionel TMCC System to run my trains and that includes an AMC motor controller. The controller allows you to select DC as a power output.

A couple observations if I may;

- leveling is fairly important especially for heavier engines and older engines that may not be working optimally. I used small pieces of cardboard to shim where needed. The card deck is a good suggestion

- be careful not to let any sawdust or foam pieces or other debris get underneath the table. I was having a bad time getting the turntable to turn all the way around. I was convinced it wasn’t level or that I had broken something. So I took it apart and found a substantial smount of crud had built up in the gear box. There’s grease on the gears to aid in smooth movement but it also creates a mess when particles of debris find their way inside.

- Warning. If you are going to take the top of the table off. There are three ball bearings in the center that st in small ‘cups’. When you remove the center screw and lift off the top the bearing fall out. Putting the top back on requires you to remove the bottom from thr table and reassemble it upside down. I learned this the hard way.

- you can take the gear box apart without having to take the top off. Carefully remove the screws from the motor assembly and the drive belt. The motor lifts out with one of the wires still attached to the frame but there is enough space to set it aside. The top of the gearbox then comes off by removing two screws. This is where I found my crud buildup. I cleaned, regreased, and reassembled the gears and motor ad now it purrs around like a kitten with or without engines.

I hope my observations help some of you enjoy your turntables.

Ron, good advice. I learned all that the hard way !

Tom

Would greasing the gears on the OLD Atlas turntable also help reduce the noise?

Or is the noise due to the motor and drive belt, not the gearbox?

FWIW, I have the older Atlas TT, and so far I find the indexing is very good. The issue with DCS is interesting, I'll be finding out about that soon as I'm working on wiring. ![]()

Has anyone installed a mini commander II as demonstrated?

Since the TT control is bang-bang on/off in two directions, I'm just using two channels of an SC2 to control rotation. I'm not sure what the MC-II brings to the party. I'm also using sixteen more channels of the SC2 boxes to control each of the whisker tracks power.

Hi GRJ. Could you expand on how you use your sc-2’s to power your side tracks please.

Thanks. I am scratching my head.

Nothing to it Ron.

The track power comes into the common of all the SC-2 relays (note that I have separated Relay #1 from aux power to totally isolate it on all of my SC-2 boxes). I wire the whisker track center rail to the N/O output of each relay of the SC-2. I program the SC-2 for all accessory control. Then I just press ACC / # / AUX2 to toggle the respective whisker track power where # is the whisker track number from 01 through 16 in my case. The last two channels on the 3rd SC-2 are used to control TT rotation, number 17 & 18, you toggle them on and off with AUX2 as well. With the Atlas, you just let it run until the Geneva drive gets to the track and then toggle off the motor. I'll leave the TT bridge powered all the time so I don't need another power control, I don't really see any downside of doing that.

I built a layout for a guy once and think I remember using an AMC to power a Millhouse turntable so you could control it with a Cab. That worked out pretty good.