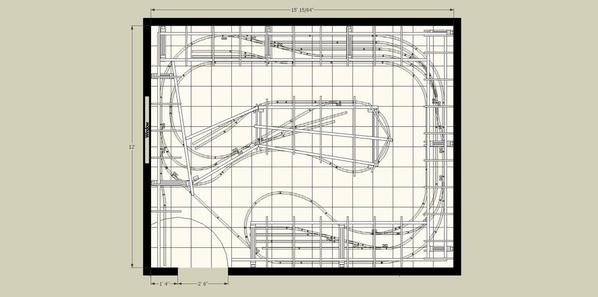

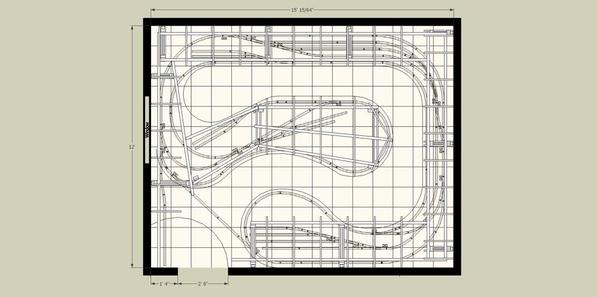

I've decided to tear out the closets and now I have a 12X15 space. I can get more operational scenes on this design. I had some questions for the forum.

1. How much space should I leave between the back wall and the center of the first track? I've using 3" on this plan. I plan on painting a rural backdrop (mostly trees and sky) on 1/8" hardboard.

2. This is a carpeted room, but I also worry about the space to the front edge. A derail could send something over the edge so how much space should I leave to the front edge? I'm using 4" here. The aisles are 18" min, but if I could steal another inch that would make it 20" which would make a bit more comfy without a redesign.

3. Would you move the crossed over turnarounds elsewhere and why?

4. If I consider putting a divider down center of the middle peninsula, Are there any ideas of how to terminate a divider when one end is a turnaround?

5. What are some examples of scenes that could fit in a narrow space. Seems a 12" wide space with a main and a siding doesn't leave much room for anything but a building front.

I would appreciate your insights.

Thanks all,

Tim