hello! first post here and since i've seen some really great ideas on the forum I thought I'd ask about my new layout. planning on building a layout in my loft using gargraves sectional track and switches and mostly postwar Lionel locos and rolling stock. I have some postwar accessories but not sure i'll use them on the layout, things like the 282, 397, 350, 456, 497, etc.

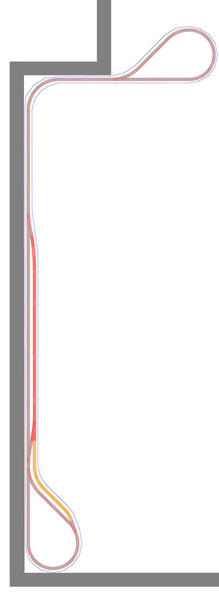

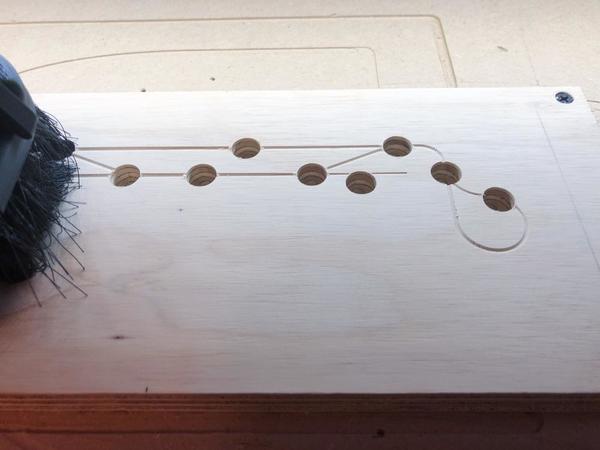

trying to come up with an interesting layout that doesn't take up too much width and represents some of the east coast main lines, NYC, PRR, etc. would like to run two trains at once - the outer loop would be for a passenger train with a siding to store an extra set of cars along the lower right wall. the inner loop would be freight with an industrial yard inside the right loop and the ability to switch to the outer loop if necessary. would appreciate any help with the yard layout to make it more functional.

Also was trying to figure out how to add some elevation with topography rather than an open trestle. maybe the long straight in between the two loops could be stacked somehow - the line closest to the wall could be above or below the other two lines. still trying to figure that out!

goals would be to keep the left loop as tight as possible (showing o32 and o42 tracks) to keep clearance at the door and to keep the straights as narrow as possible because there will be a sofa in front of it. the right loop can't be much more than the 8'-7" shown but if there's a good reason to make it wider I could probably do that.

thanks in advance!

at

*updates below*