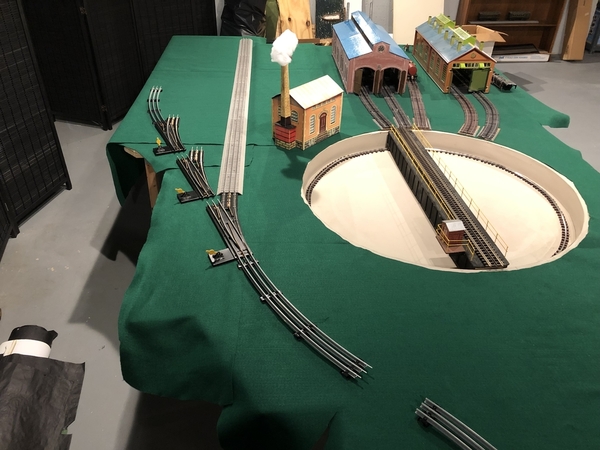

Green felt - I should have thought of that when building my L-shaped layout. I used the "standard" green patio carpet, which has worked out well. I pre-decided not to paint the layout platform surface -- "too plain."

Although it's noticeable, I placed 3/8ths-inch brass grommets in all drilled holes with a spot of T6000 glue, then dressed the wiring through it to an accessory, lighted building, or switch. The grommet prevented carpet unraveling and (to me, at least) it presented a "finished look" instead of a bare hole. If/when I must move an accessory to another location, I can pry the grommet loose. The carpet fibers tend to close and cover the hole. I use a small hand-held vacuum (by Woodland Scenics) to spot-clean the green carpet - it will pick up drill shavings and carpet fibers.

It's all in the details ...

Mike Mottler LCCA 12394