Okay. Here's what my thinking is. First polarity. There is no "polarity" in AC current. It's like a whipsaw, current goes from the base side of the secondary winding to the hot side, then in the second half of the cycle current ALTERNATES and runs from the Hot side to the Base. Back and forth, back and forth. So which rail is base and which one is hot in my understanding does not influence which way the AF engine goes. I know you can make an armature spin in different directions, maybe that's make use of somehow. Anyway, direction-changing as I think of it is handled by dropping the voltage to zero, having

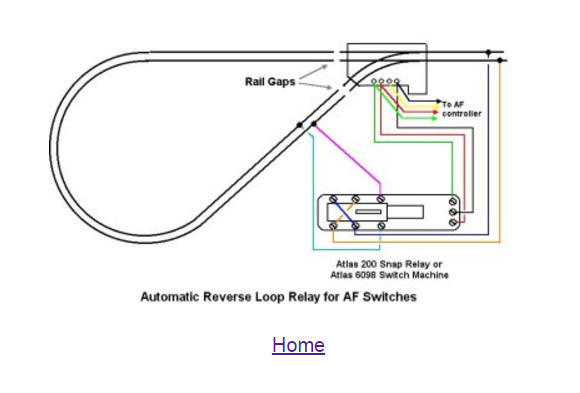

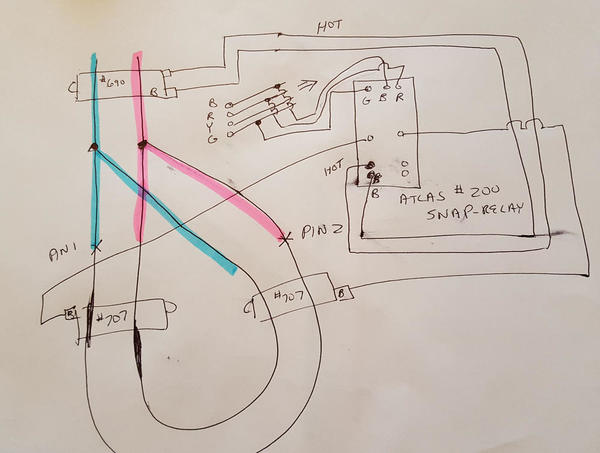

the reverse unit kick in, then supplying current again makes the engine go in the opposite direction. So the "danger" in loops and wyes isn't suddenly having the engine change direction due to "polarity", it's from a dead short - see fig 1. When the 2 wheels span the insulator pin you get a dead short. THAT's what this whole setup is trying to avoid - quickly changing which rail is base and which one is hot without any voltage drop - one that the system can't react to say in milliseconds.

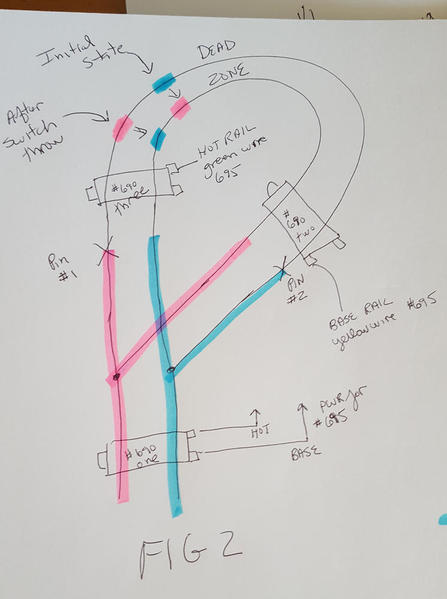

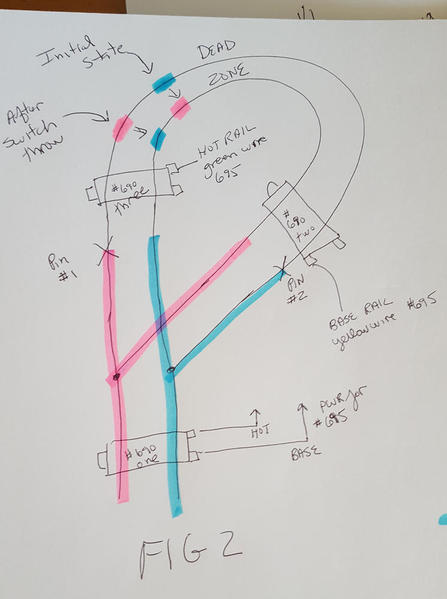

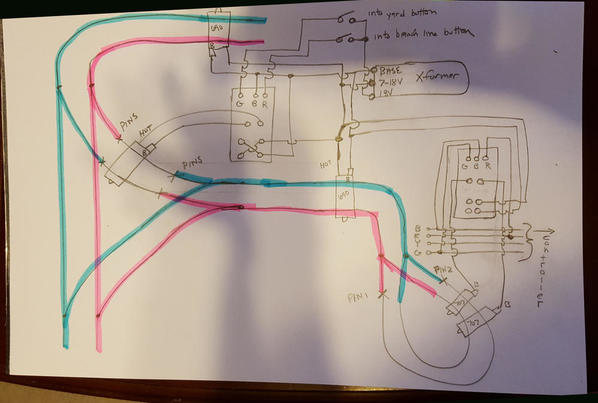

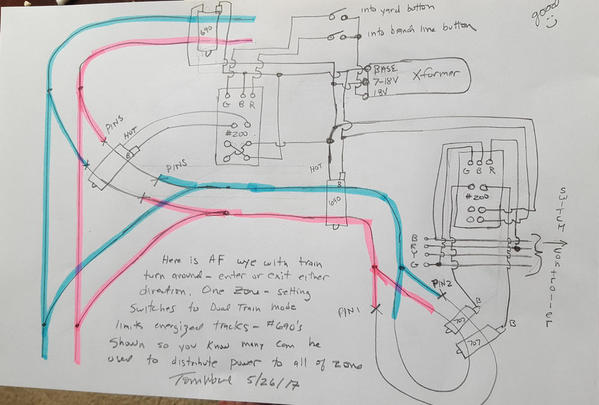

Figure 2 has lots going on. Before the 695 relay is connected by virtue of the insulated pins we've created a dead zone in the loop. Look at the bottom of Figure 2 where the pink (hot) and blue (base) rails are crazy "y's". The engine is heading into the curved turnout part of the switch toward Pin #2. When it gets there, we've done 2 things - because the switch is in dual train mode power to track beyond the switch is controlled by the switch itself, so if the switch is set to the turnout then no power goes to any of the track connected to the straight section extending past the switch. So when heading for pin #2, the track has power to the turnout and with the 695 connected the "Initial State" of the dead zone (most of the loop) necessarily matches that of the turnout and the train keeps going without shorting out. At some point while the engines are in the loop the switch is thrown (later I'll use electronic track trips to do it automatically) then for the engines in the loop which rail is hot and which is base are reversed, note this is no "polarity switch" these peaks and valleys of current just keep on a coming. What has been avoided is the dead short when the engines reach pin #1. Okay, next step is to draw the same diagram for the wye ...