My Lord! Things actually went smoothly today!

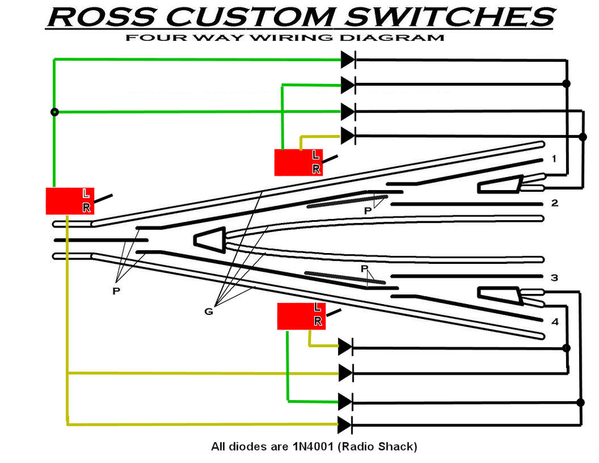

I hooked up three DZ-1011 dwarf signals through 1008 relays to indicate turnout position. Plus the last two switch machines were wired. Everything works (see circuit diagrams from 2-19 and the correction from 2-26).

I wired the one dwarf signal to the switch motor previously wired just to make sure the connections were correct.

I then wired the other two switch machines made sure they worked then their companion dwarf signals. Everything works just fine.

Because the 4-way was moved to a new position as mentioned earlier I had to move terminal boards under the layout to accommodate the new position. As a result almost all wires from the switch motors and the dwarf signals were too short. I am not much on soldering so try to avoid it as much as possible. To splice wires together I use a combination of wire ferrules and crimp splice connectors. My process is shown below.

Note I am using 22 gauge wire which is way too thin for the normal red crimp connector plus I never liked crimping a bare wire into a connector. They too often pull out (probably my technique).

I first crimp the wires with 22 gauge wire ferrules (blue)

These ferrule are too small for the standard red crimp connect but an 18 gauge ferrule (yellow) fits snugly. So I crimped the 22 gauge ferrule into a 18 gauge ferrule.

I then crimped the ferrules from the two wires into a standard splice connector. These wires are going no where.