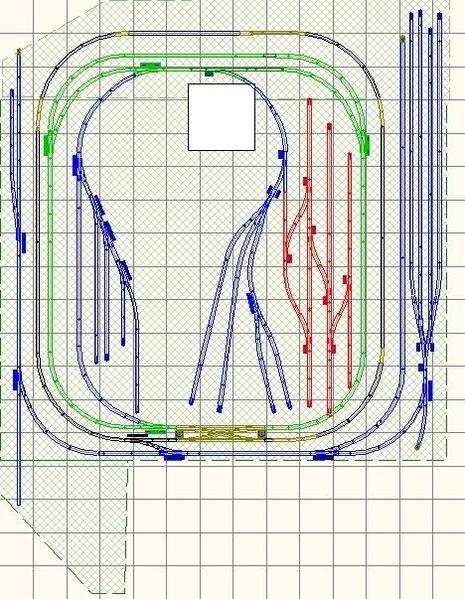

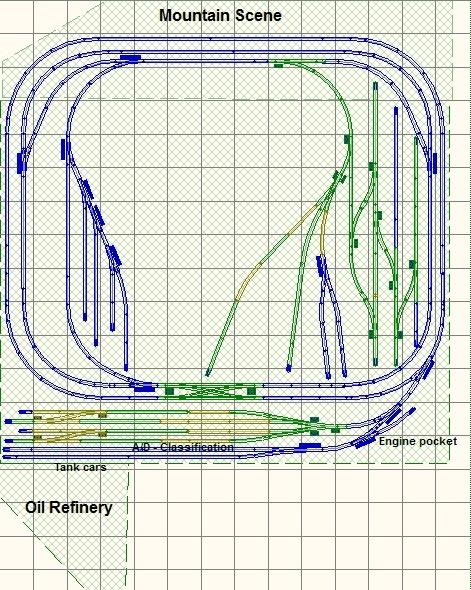

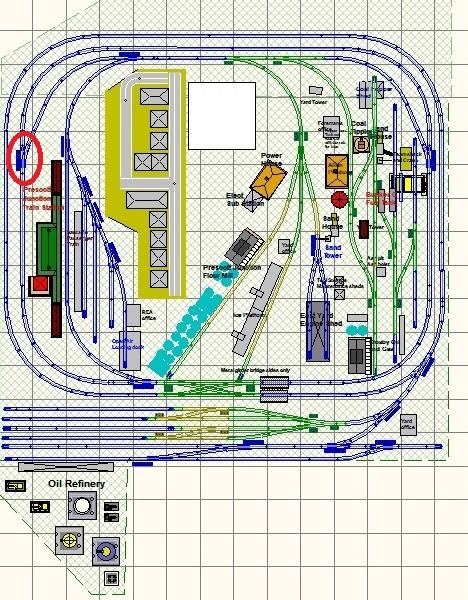

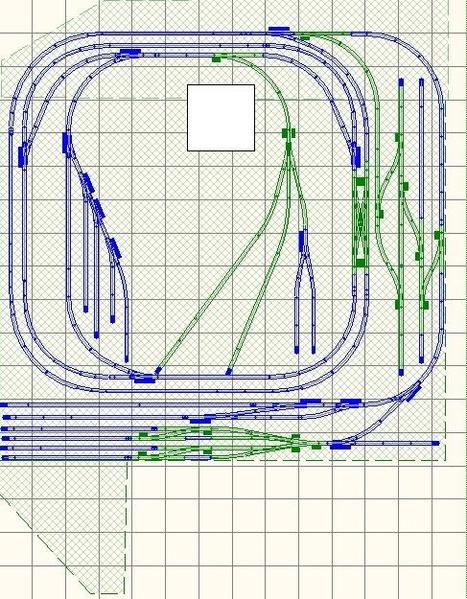

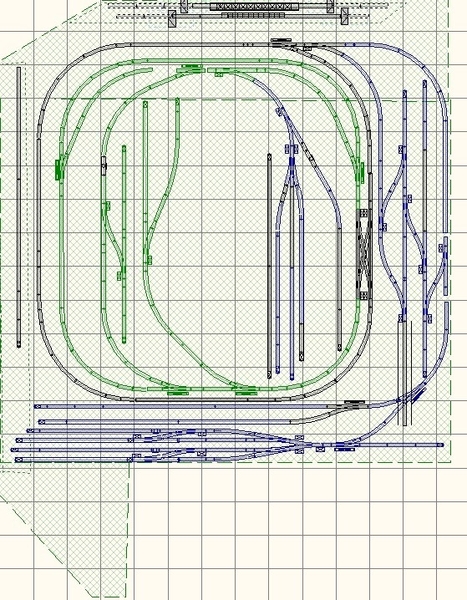

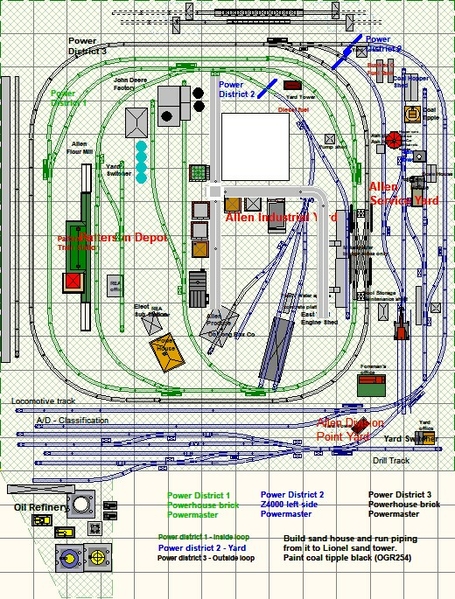

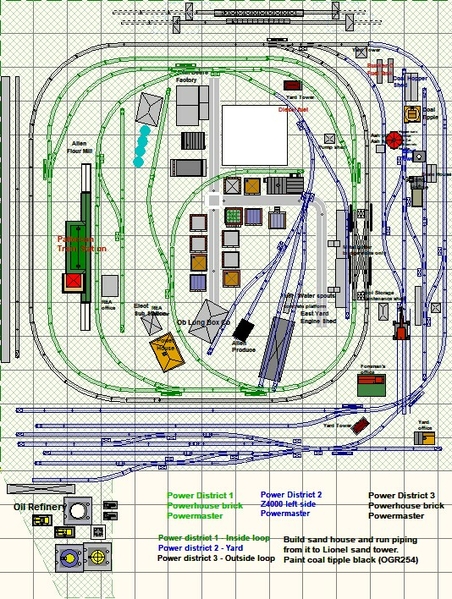

As I find time I am building a new layout. The figure below was my 'original' design. I had the yard work wired in then showed my design to a friend who I consider a hi-rail expert. The track module outlined in red is a half copy of John Allen's Timesaver switching game module. My intent was to have something for my friends to do when they came over other then watching trains go round a circle.

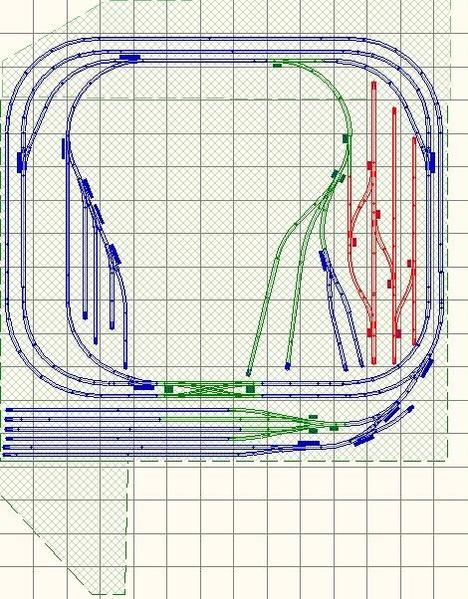

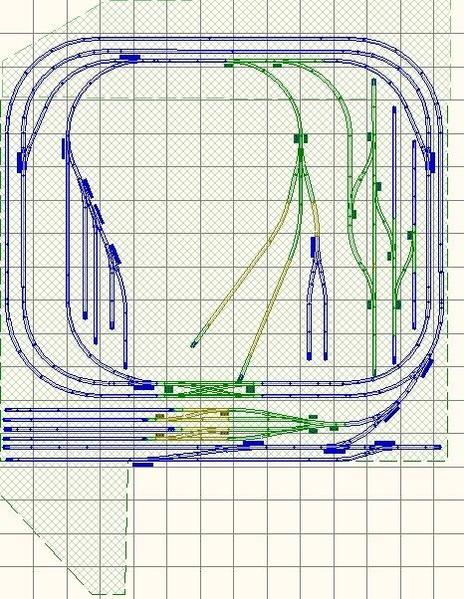

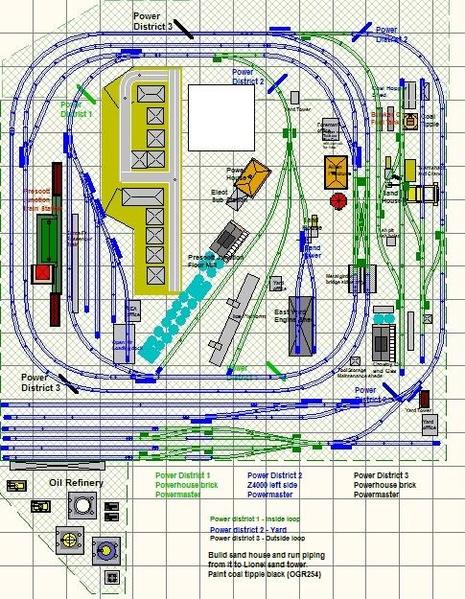

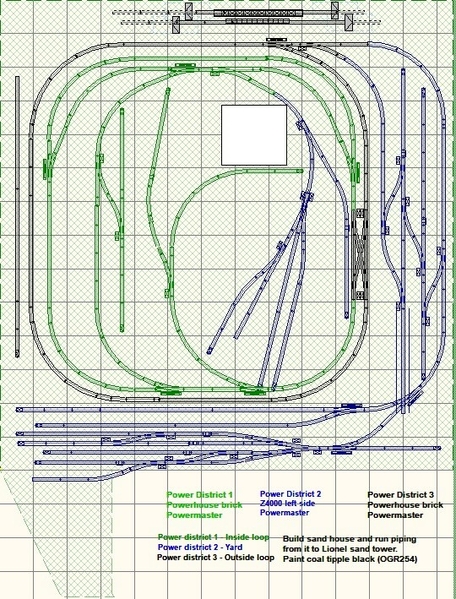

When I showed the design to my friend Peter he pointed out that the Timesaver module was too far inside the board so it would be difficult to place cars where needed to start the game - something I never thought about! Peter made some other suggestions. The bottom line is the design below.

With the new design I should be able to reach in to place cars (furthest track is about 30 inches in) plus I still have the yard where I can reach individual cars to manually uncouple them. Down the road I want to install some turnouts at the end of the yard for an engine run around track.

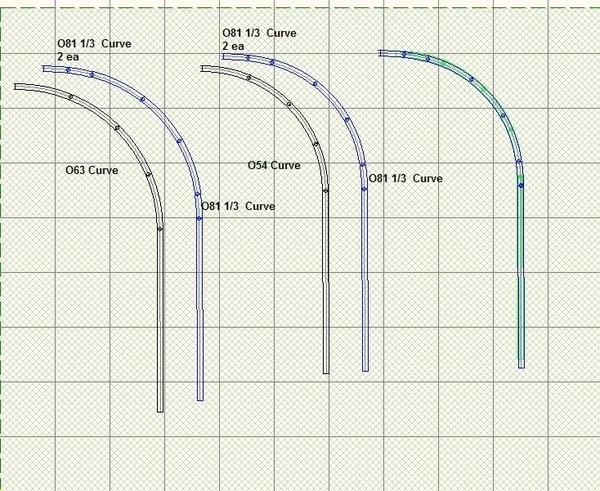

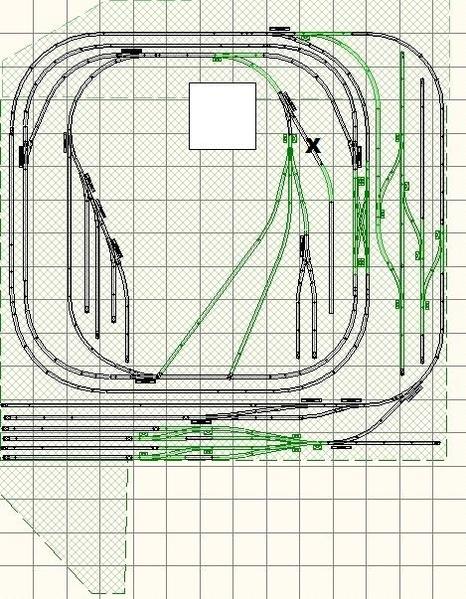

Another good thing about starting over is that I discovered from the reading a John Armstrong book the wonderful world of easements. For various reasons I chose to run O63 and O54 curves on the main lines so easement will come in handy. Since I don't have any flexible track I found out if I use O81 1/3 curves - two going into the curve and one on the end, I end up with the same total curve pattern in area - see below. This is not much of an easement but I think it will still make the trains look better going into and out of a tight curve.

The last curve on the right is actually both the all O54 placed over the one containing the O81 1/3 curves. It is a almost perfect fit. Note this particular track is Atlas O. I started out with Atlas O sectional track so have a good inventory. However for any new turnouts or track I use Ross. A lot of the interior siding and yard work is all Ross. Since Ross does not make partial curves probably the best course would be Gargraves flexible track or cutting down an O81 sectional curve.

Joe