That sounds tricky, but worth a try. I also think I'm going to deep six that thundercloud and replace it with something that looks less like a nuclear explosion.

I like the idea of the thunderhead, I think it turned out pretty good, can you get lightning? And Ben franklin with kite? Then some utility trucks with flashing lights? and some trees down, with sparks on down wires then you can make the town lights blink and the sound of little generators. people cutting tree limbs. The lionel remote crane clearing the right of way. of course the orange barrels and yellow caution tape. A train of flat cars with FEMA housing units. Maybe a tornado in the distance. I think you need more room![]()

I'll see what I can do. I'm good at painting trucks and such, but don't ask me to paint people... Ugh!

The clouds are now finished, at least as finished as I want to make them. From the "revised" thunderhead to the right are the clouds from last session. The ones to the left of that are all today's work. I perfected my technique a bit with Bob Ross' help. He does make it look easy. It's really not. I also toned down the first ones that I did since they looked a bit "extreme" to me. The biggest challenge was figuring out how many of them looked good versus how many I felt like painting. I really want to build a railroad, not be a mural painter. My wife thinks the whole "cloud thing" is silly.

This a horizontal panoramic shot which photo-stitched pretty well.

I made the thunderhead fatter and took away the "atomic mushroom cloud" look a bit. It's still weird, but my grandson and some of the readers liked it so I didn't paint it out of existence.

Here's another shot of the room.

Starting tomorrow, I'm going to start building. I'm also helping my now 11 year-old grandson (birthday yesterday) finish up the super hornet. It had a massive amount of decals and some very large which were beyond his skill set to handle.

Today is momentous day, The Olympics started. Besides that! I began actual construction on the layout. I cut the wood for the four brackets that will be mounted on the back wall to support the rear part of the layout. The brackets are supported by a 2 X 2, with two 2 X 3 arms and a 2 X 2 angle brace. The main components are fastened together with 1/4" carriage bolts. The angle bracket to upright connection will be with Spax wood screws and gussets.

The end brackets will also have a horizontal sway brace facing outwards that will make the whole think more rigid. Once all the ply pieces are in place, that will also stiffen any horizontal motion. It's nice to have a good chop saw and I just added a big, DeWalt 18 Volt Li-ion, 1/2" hammer drill. This thing is a bruiser and has three modes and three speed settings. I needed to up the horsepower to handle the concrete drilling tasks AND handle the fastening of thousands of screws. That's a fact, it's over 1,000 fasteners to hold this thing together.

The bottom of each upright has large diameter carriage bolt feet. I epoxied "t" nuts into the bottom and then screw in the bolts with a lock nut halfway in. This gives me a lot of adjustment for uneven floors. This is the same scheme I used in building the existing part of the layout.

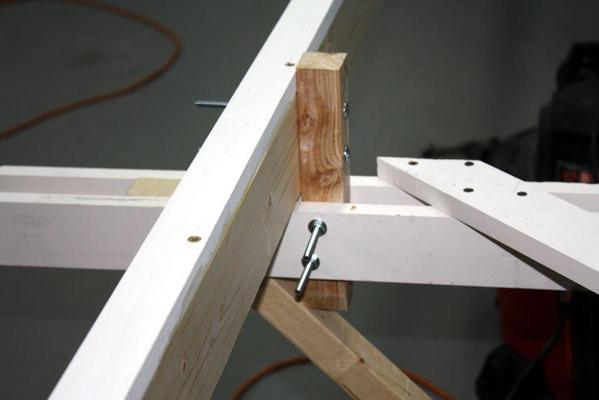

Here's the bracket fitted with the diagonal brace. Even though it's only a 2 X 2, when properly braced and having the load directly into the length, it's very strong. Kind of like building an airplane rather than a barn.

In the next couple of days I'll finish the assembly, break them apart to more easily mount the upright to the wall and then reassemble them in place. The uprights will be held on top with a 1/2" wedge bolt, and the bottom with a smaller (lighter) Tapcon. With a cantilevered bracket, the main load is on top, and through the angle bracket to the foot.

Finished building all four brackets and then decided to attack mounting one on the wall. Needless to say, I'm out of shape. Hopefully, as I keep working at this I will be less worn out. The back is quick tender from crawling around on the floor on my knees and boring that 1/2" hole in concrete. That was hard!

I also built the first sway brace and mounted it too. The result is a very strong assembly that easily supported my 185 pound weight without deflection. They will work as designed.

Here's a completed bracket:

The top of the vertical is held to the wall with a massive 1/2" wedge bolt. To mount this you drill a 1/2" hole 3.5" deep into the concrete, hammer the stud into the wall, put the wood over it, and tighten with a deep socket wrench and finally tighten to 55 ft. lbs. with a torque wrench. Since I was fastening it into wood, it was difficult to get to that tension since the wood was crushing. It's actually at about 45 ft. lbs. and is very tight to the wall. The tension on the top bolt is almost all pull-out. It was why I went with wedge bolts since their pull-out is very high. I was told to not trust Tapcons for pull out. They're better in sheer. I first drilled a clearance hole through the wood and marked the center onto the cement. I then used the smaller Tapcon carbide drill to start a hole to secure the location. I double-checked its alignment with the hole in the wood, and then removed the wood and went at it with the 1/2". The DeWalt hammer drill performed well and battery life was terrific.

The bottom is held to the wall with a long Tapcon. In the bottom location, the stress is much lower so a lighter (and easier to install) fastener works well. In this picture you can also see the gussets holding the diagonal brace firmly to the base of the vertical. This method is used throughout building leg sets when creating an L-girder model RR. I figured 8 screws are sufficient to hold the both side of the gussets. To do all the drilling I had to disassemble the bracket. I may use a washer under the Tapcon to enable it to support more. Also note that I'm using 1/4" ply for the gussets. That's actually a sheet of German plywood that was unused and moved back with me from Germany in 2002. Never throw out good wood!

While the bracket appeared to be very strong in a straight vertical load, it was very unstable side to side so the sway braces that I decided would be needed, were in fact, needed. I used the left-over ends of the 8', 1 X 3s that I used for the horizontal member. I cut 45º angles on the end for neatness, and made a 2 X 4 mounting block that would serve as a backing for the lug that was to hold the sway brace. The mounting block is held to the wall with two long Tapcons. While there is some pull-out loading, at least half of it is sheer. There's also no dead load on it like there is with the top wall bracket bolt. Once the ply is in place, there will almost be no lateral loading unless someone falls into the layout. After I mounted the block, I cut a chunk of 2 X 2 for the lug and mounted it will some long deck screws. I always drill pilot holes when fastening anything. It ensures that the upper piece pulls down tight and makes it much easier to drive screws. I use three power drivers which makes for less drill bit swapping.

And here's the other end. Four 2" cabinet screws hold this end of the sway brace in place.

Just three more to mount and then it's onto building some new L-girders for the rear of the layout. The large stud will be hidden because there's a lot more stuff that goes onto the bracket that will raise the height of the layout to the finished 42", so I probably won't have to paint the vertical sky blue.

As a birthday wish... I worked on the railroad today. I started with the first trip to Home Depot to buy the wrong length Tapcons, some new Titebond Glue, a better 5/16" nut driver that won't round out when driving Tapcons, and some shorter deck screws.

I then began work. To make it easier, I moved my temporary work table—an actual park of the train old layout that will be returned back to its initial purpose—into the middle of the room where I could assemble and drill the brackets without crawling around on the floor so much.

When I tried to chuck my long, fancy 1/2" Bosch (made in Germany) hammer drill bit it wouldn't center and wobbled all over the place. it was actually doing that when I drilled the hole for the first bracket, but it didn't dawn on me why. So I looked at what was going on and realized that the Bosch bit was designed for their heavy duty hammer drill and it had four milled grooves on the shank to lock into the Bosch unit. But four doesn't go into three and the three-jaw chuck couldn't center the bit so it ran horribly off-center.

So it was back to Home Depot before I could go any further. They took both the wrong Tapcons and the lightly used Bosch bit. I then bought a hammer-drill bit that had a straight shank. It also didn't have to be so long. I had originally thought that I'd have to drill through the 2 X 2 and then the wall for more than 3 inches with this bit. But that's not how I'm doing it. I'm pre-drilling the clearance hole in the 2 X 2, marking the hole with a sharpie, moving the wood aside, pilot-drilling a little hole with the Tapcon drill, and then using the big drill to make the 3.5" hole.

As a result of experience being a great teacher, I got two more brackets mounted, and started preparing for the brace that's going into the inside corner on the back wall.

I then noticed a slight problem. On the existing layout pieces, the L-girder's bottom is 34" above the floor, but on my brackets it was only 29". I don't know where the error crept in, but it's not serious. For the first two I mounted, I will simply mount the L-girders onto a 2 X 2 bolted vertically in between the two horizontal braces high enough to match the height of the other girders. For the back two brackets, I just raised them off the floor so the horizontal braces are 34" off the floor. All of the load is handled by that massive wedge bolt and the Tapcon. Very little load is transmitted to the floor anyway (I hope).

For the setback wall, I was going to simply Tapcon a 2 X 4 to the wall that would stick out the same distance as the brackets, but I didn't have a 58" piece of 2 X 4 so I decided to make a short L-girder and use that. The line on the wall is at the 34" level.

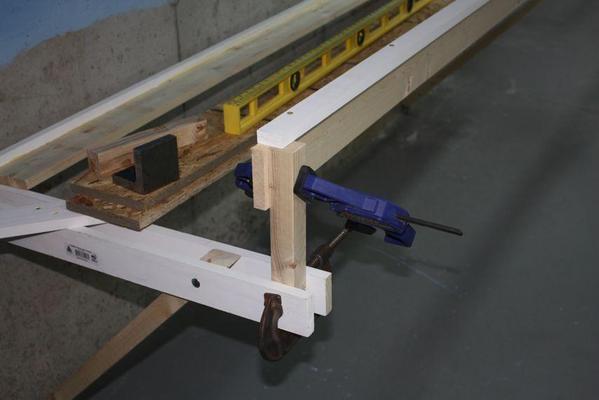

L-girders are very strong and when properly braced have very little flex. I first clamp the 1x2 to the edge of a 1x4. I used enough clamps to try and eliminate as much warp as possible. I then install wood screws about every 8 inches. These will be removed eventually. After the screws are in I removed the clamps, remove the screws and take the two pieces apart.

Then you put on a layer of Titebond (or other carpenter glue) and resinstall the screws to hold it all together and aligned. When the glue dries the next day, remove the screws since they're no longer needed. You could leave the screws in, but a) they cost money, and b) when you're drilling and fastening the joists you will invariably hit one of those now-not-needed screws, so I take them out and reuse them.

Here's the newly built L-girder before I remove the screws.

I'll document this corner wall brace next work session.

"Picture's worth a 1,000 words..." I described how the corner brace was going to work. I had an hour after I got back from work today and installed it.

So... 4 down and one to go.

I love how structures get stronger and stronger as you add diagonal members. It's a great lesson in geometry.

With the additional bracing it's very strong. I was going to use three 1/4 X 2-1/4 Tapcons, but you only see two. It appears that my super DeWalt drill can break them off when over torquing. I'm also using washer under the heads to spread the load onto the wood.

Here's one view showing the L-girder attachment points. Even with two Tapcons, that beam isn't going anywhere. It also shows the mounting block on the wall for the diagonal support brace. It's held with two Tapcons.

Here's the other side showing the sway brace. I was able to have the bracket sway brace mounting block perform double duty. The brace is held with some 2" drywall screws on both ends. The small mounting block on the right end is held with the long deck screws. I like the deck screws because they use the Torx held slot which is very hard to cam out. You don't need a lot of vertical pressure on the power driver like you do on a Phillips head screw.

Just for the pictures, I laid one of the old L-girders from the previous railroad across the corner bracket and the right-most bracket, and then measured how level it was across. Taking care to measure the mounting height produced a perfectly level line from those two.

While this attention to detail may be a bit anal, I find that the more carefully all this infrastructure is laid in, the easier it is to level the subroadbed when it's time to install all of that. Plus, it makes for a very tight and light construction that will last for years and years. The nice thing about L-girder is there are almost no parts that must be cut to a specific length since all members lie across one another and there are no butt joints.

Trainman2001, have you had a chance to visit the Air Force Museum yet? I went last year, in September, on my way home from the O scale convention in Indy. I was truly IMPRESSED!!!!!!! My favorite plane is the F4 Phantom and they had, at that time, a cockpit of the F4 that you could actually sit in. I didn't want to leave. Truly a MUST see for any Air Force fans. I was checking out these 2 jet fighters and thought it got kinda dark all of a sudden. When I looked up to see if the lights went out I realized the 2 jets were under 1 of the wings of the B-52. WOW!!!

Anyway, Have a great trip. Rick

Yes we did! Between my grandson and me, we took almost 300 pictures which I triaged down to about 230. I had lots of favorites; all the B's (17, 36, 52, 29, 2 and 1b) and the thermonuclear weapons that they carried. It was a very spooky feeling being up close and personal with a mockup of a multi-megaton bomb. I also like looking at all the different landing gear and studying the details within the wheel wells. My grandson loved the Valkyrie as did I and lets not forget the F-22 and it's F-135 P&W engine on display next to it.

Here's a shot of me standing next to the B1-b's monstrous landing gear. (I know this isn't in the theme of this thread, but you have to admit, it's pretty cool).

My grandson wants to go back again. This time maybe we'll take his dad and little brother.

Attachments

Back to train layouts...

Installed the last wall bracket today so all the concrete drilling is now complete...gladly.

I did some checking. The pull out and sheer strength of the 1/2" wedge bolts is both 4,600 pounds. The weight of the entire railroad won't be anything like that, so I have no worries at all that the brackets can't do their job effectively. The wood itself will shatter before the bolts leave that wall.

Here's all five wall brackets now in position.

With the brackets in position, I was ready to start making L-girders. I don't have a work table available for an 8 foot girder-making job, so I put the brackets into good use already.

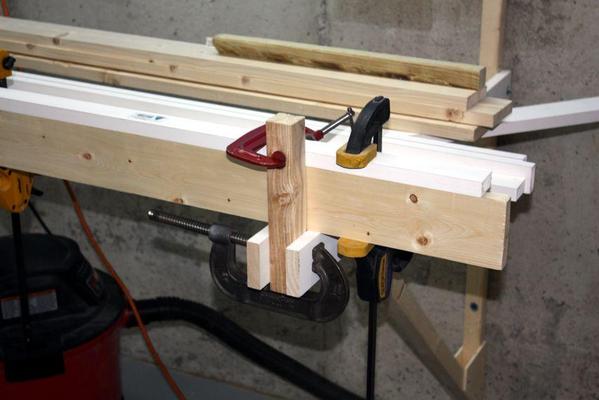

I'm supporting the 1X4 on its edge by inserting a 2X2 between the horizontal bracket rails held with a c-clamp, and then clamped the girder web to this.

With the web stabilized, I was able to clamp the 1 X 2 flange on top in prep for screws and glue. This process goes pretty fast and I was able to glue up four girders that will stretch the entire length along the wall across all brackets in a little over an hour.

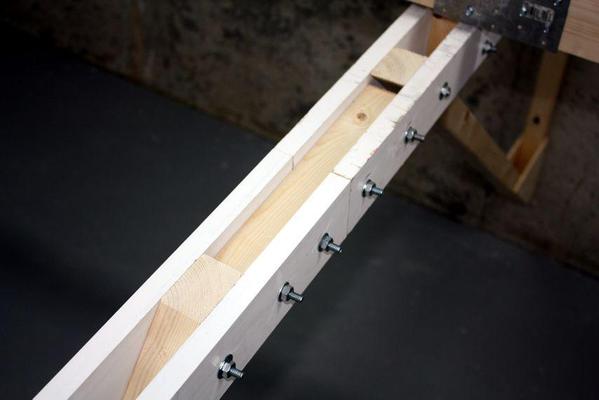

Here are four girders waiting for the glue to dry. I offset the flange by 3 cm so the flange and web don't fall directly in line with each other. The longest run which goes across the back wall from one end to the other will use 3.9 girders spliced together so these four represent 1 long girder.

While they were drying, and before I remove the screws, I decided to start figuring out how to mount them onto the brackets. As noted earlier, the first brackets I installed are about five inches lower than they should be, so I need to put a riser in place to end up with a level girder. Here's the riser in place that levels the girder with the corner bracket (which is at the correct height).

Notice how neatly the 2 X 2 sandwiches between the bracket horizontals. I'm going to use one or two carriage bolts to fasten the riser to the brackets and the girders to the risers.

Here's another riser at the other end. Each riser is 10.5 inches long and the flange rests on the top when level so putting it together will be a snap.

Nothing's in its proper place here, but the theory is now proven. Next session, I'll remove the clamping screws from the flanges and start mounting the girders AND splicing them together. In Kalmbach's Benchwork book, they talk about using a piece of web that 2X its width in length to bridge between to girders to make a splice. When I built the layout in Germany, this is how I did it, but when I enlarged it in Pennsy, I used Simpson Strong-tie metal hardware to make the splice. It worked well and was easier to work. Splice plates are used on both sides of the web with lots of fasteners.

Attachments

It's amazing what you can accomplish when you have three solid hours to work on the project. I got the two rear-most L-girders in place, leveled and tied in. This required building two more 8' lengths and installing them. I used two different means of tying the girders to the support structure: deck screws or their equivalent, and 1/4" carriage bolts. For the rail that butt up against the bracket vertical support I used the deck screws since there was no effective way to get behind the bracket for the other side of the bolt. But on the free-standing connections I used carriage bolts which are immensely strong and really lock the structure together. The long 32 foot girder is not dead straight when sighting down its length, but it doesn't have to be. The joists that go on top, just lie across the girders and are fixed at each end with one screw. The amount their ends stick out doesn't matter.

Here's today's progress looking from both directions.

Here's some details of the joinery involved.

In the first instance, I used carriage bolts to hold the riser to the beam since I could see both sides.

This next one is a full, free-standing support. You can't help noticing that the carriage bolts are wayyyyy long. I'll trim them with the Dremel and a cut-off disc in the next work session. I was getting tired and didn't want to tackle a step that could easily get a little out of hand. I didn't want to rush it.

The last example is using deck screws into the bracket upright. You can see that it's sitting above the bracket due to leveling requirements. Note also, the relief cut I made so it would clear the sway brace. When I chose to install the sway braces on top of the brackets, I realized immediately that I needed to add relief. I used the saber saw to make the cut. The other choice was to mount them on the bottom of the bracket, but I didn't relish the thought of putting in the screws upside down.

While the straightness of these long girders isn't critical, it is important to make sure that they are square. I trued up the free-standing with a machinist angle block. Even perfect level isn't critical at this stage because the T-blocks and their risers are individually leveled and cross-leveled before the sub-roadbed is laid on top. I just like stuff level as I go along since it ultimately makes everything a little easier.

I used Simpson Strong-tie splice plates to hold the girders together. The plates are on both sides with 8, hex-head, self-drilling sheet metal screws holding them in place. They hold the girders very securely. I've used up my stash from the previous layout and I'll have to buy more. I have Phillips head screws that are designed to fit the holes in these plates, but they're too long and leave sharp points sticking out whenever I use them.

This waste pipe caused a slight field alteration. I had to space the girder off the bracket upright a bit so it cleared the pipe. On piece of 1X2 between the girder and bracket was sufficient. I just drove the screws through both pieces. I always drill clearance holes through the piece to be fastened so they pull down nice and tight. The layout turns 45º from the end of the back girders. There is a crudely constructed shelf just out of view on the left in this picture. It's holding all of the trains in their boxes right now. Once the layout is finished, I'm going to demolish it. I will give me more train space, or more access around that curve. The train boxes can be stored under the platform.

You can also see that the girder is lifted about five inches above the bracket. In an earlier post I explained that for some reason I built the brackets too low. I looked at my drawing and realized that when I first sketched it out in CorelDraw I wasn't actually worried about the height, I was just playing around with the structure's design. Somehow, I had forgotten that this was just a notional sketch and I took measurements off of it. Of course they were wrong since I never used any when making the design. In the other two brackets, I compensated by raising them higher up the wall so I didn't need to lift the girders.

Attachments

Finished putting up the three girders that line the back of the layout. It was a very productive day. On the right end of the third girder it's sticking out into space so it needed an auxiliary leg. I thought about how I wanted to extend the wall bracket another 24" to capture the leg and came up with a simple approach that was facilitated by have the double horizontal pieces. I simply inserted a 2 X 2 in between the horizontals with 5 inches captivated and five extending outwards. This was clamped with two carriage bolts. I then added the two 24" extension horizontals and bolted them the same way. This made it easy to capture the vertical 2 X 2 which was going to be the leg.

Before cutting the leg, I wanted to have a leveling foot. Unfortunately, I used up the last T-nut on the wall brackets, but on the last two wall brackets, the ends weren't even resting on the floor so the T-nuts were superfluous. "Ah..." I thought. All I have to do is get it out now that it's epoxied in. With some prying with a screwdriver and sheer determination, I got it out and glued it into the end of the new leg. In this case I used Gorilla Glue instead of epoxy.

Here's the detail shot of the extender in place. No comments about the clean shop please... I just vacuumed the entire place. My wife hates the shop vac. I actually tossed the one I had at the old house because it screamed so much. I bought a new Craftsman that was supposedly quieter. It is, but now it's only 100db instead of 120.

To brace the leg in the width direction I added another 2 X 2 angle brace that was also sandwiched in the now-added horizontals with a single carriage bolt just like I did with the wall bracket diagonals. For the other end I used the gusset method. I needed to cut more gussets and I knocked them out with the circular saw this time, which was more consistent than the saber saw for this purpose.

Even more critical with legs than the wall brackets, the legs need another brace in the longitudinal direction. Here I used the same process as in all the other legs previously built; a gusset at the leg end with 6 screws and three screws at the top end directly into the L-girder.

Here's the detail of the upper end.

And here's the detail of the connectors on the other end of this assembly where I had to make up for that 5" drop as explained earlier. Two carriage bolts in each direction make this structure solid as a rock. (Sorry about the focus on this one)

So here's the entire rear array looking from both directions. I've decided to go with the grade based on keeping the railroad less boring. Next step will be to start designing the joists and risers to support the sub-roadbed planks on the backside of the layout.

I hope you can start to see the elegance of L-girder construction. It looks frail, but it's quite strong.

Attachments

Let me start by noting that I made a big mistake... I decided to spend yesterday evening reading all about Patrick K's layout progress and now feel completely inadequate. I think he is super-human. No one can build that much layout in that short length of time. I simply can't understand it. I was even thinking that who would care about my puny effort after seeing what he's done. But then I thought, yes, but... what I'm building is far more in the reach of average railroaders so I will continue posting.

By appearances, yesterday's work session didn't accomplish anything resembling Saturday's marathon session, but looks can be deceiving. I unpacked all of the old L-girders that will comprise the rest of the framework. They were all duct-taped in bundles from when we moved. I have most of the girder lengths noted on the master print and if they're missing I get them from the computer drawings. My original plan had the new girders and old all mixed up since I was attempting to use the old girders in their actual length. I was going to use new girders to fill in the missing pieces. But as Clauswitz said, "Strategy ends when the first shot is fired". Once I started building the wall supports I decided to build all the new girders for the back wall and use the existing ones to build the rest. As it stands now, I probably have enough old ones to complete the layout. I have materials for three more 8 footers if needed.

Tomorrow my grandson's coming over to finish up his Super Hornet. He and his family just got back from London where they watched the Olympics. It was quite a trip and the kids should have a lot to tell their class when they answer the perennial question, "So what did you do with your Summer?" While he's working on the plane, I'm going to work on the railroad.

I then started laying out all the girders on the floor based on length in their respective locations. After that I'll set them up at their correct separation distance and compare that to the leg sets that are already constructed. To save labor, I'd like to use as many intact sets as possible. If I have to adjust their separation distance, I'll reset the cross-braces to the needed width.

I have to keep reminding myself that the work table in the middle of the room is actually part of the new layout. As I mentioned before, I cobbled it together as a work table to build the wings of the 1:16 scale RC B-17 that I built in 2010. Right now I need that table for plans, tools and screws.

The goal is to get OSB onto the back girders ASAP so that it can be enlisted as the new work surface. Then I'll dismantle the existing table and incorporate it into the layout.

Attachments

Trainman,

Whereabouts in town are you located? If you were to need some assistance with your project sometime, feel free to ask.

Have you paid a visit to Roundhouse?

I see you like all things Aviation. Are you aware that the Collings Foundation Wings of Freedom Tour is at Clark County Airport, through tomorrow (Wednesday 8 Aug 2012). They have a B-17, B-24, & P-51C in attendance.

I live about a mile north of Roundhouse just off of Brownsboro, Rd near where it intersects with Seminary Drive. I've spent some time at both Roundhouse and L&N, but it was all before I finally got started on the rebuild. The next visits are going to buy stuff.

I believe I can use help and it won't be long now. We can take this off line. My email is mmarcovitch@gmail.com. I didn't see how you can send private messages on this forum. Is there a way to do it?

Is that Clark County, In?

One of things that made me happiest (besides being less than 2 miles from our daughter and her family) moving to Louisville was the presence of two good train stores and at least one great hobby shop. In Bucks County, PA where we moved from, good hobby shops were getting harder and harder to find and they were much farther away. There were trains stores, but considering the population of the region (almost 5 mil.) there should have been more, much more. Louisville is a great modeler's city.

I finished laying out all of the girders on the floor, and went back to the computer to determine some reference points as the erection process begins. I measured from the back walls to the extremes of the front girder and marked that distance on the floor. I also measured off where the leg sets would go (5 of them) at 8 ft. intervals. Eight feet seems like a reasonable span for the girders. When all braced up, there's no downward deflection at that spacing.

The front main girder set has a girder face to girder face distance of 40". My old legs sets are somewhere about 24" apart, so they needed to be reconstructed to work in the new design. Here's the "before" girder picture. I wanted to use the old legs since they already have the elevating screws and t-nuts installed on their bottoms so why reinvent them.

I removed the X-bracing, saving the 5-50 Spax metric screws (these go back to when the layout was originally constructed in Germany), and the lumber which will be put to good use making joists that lie across the girders. I then cut a 48" piece of 1 X 3 that served as a spacing beam. The legs were made of German metric-sized lumber. Their 2 X 2 is 44mm square, and is more substantial than our 1.5" dimensional lumber (38.1mm). I fasten one screw on one corner of the spacing beam, and square that corner up. When square I drive another screw to lock the geometry. I again used #8 X 2" Deck Mate screws with star drive. I can remove them and re-drive them over and over without destroying the star drive socket. When the first side is tight and square I did the same with the other leg.

When I first starting doing this task, I was doing it on the concrete floor with my rubber knee pads. My back was letting me know that this was not the best approach, so I got a piece of OSB, threw it on the back installed girders over a few 1 X 3s and did the work standing up. Much better!

I cut the X-braces from fresh 1 X 3s since they're pretty long. There is no worry about losing square since the two screws on the spacing beam were tight so it was just the repetitive task of lining up the X-brace, clamping the near end so I could position the far end, screw far end tight and go back to the near end, put it one screw, remove the clamp and then put in the other screw. Turn the entire assembly over and put on the opposite X-brace the same way. The ends are beveled and I'm careful to not let it extend past the leg as shown here. The reason for this is to not foul the gusset plate that's going to be installed at the bottom for the longitudinal braces, and to not interfere with installing the girders on the top of the legs.

Here's the two braces installed.

Once the X-braces are in place the spacing beam is removed since the legs can no longer change geometry. I used the spacing beam for the next set of legs ensuring that all the leg sets for this part of the layout would have the same spacing. All five sets took a couple of hours to reconstruct. Here's four of the completed legs.

When I finished the legs sets I turned my attention back to the girders. I used the wooden splice blocks from the old RR to tie together the separate pieces of girders making up the system. I re-used the 5X50mm screws on these plates, but they are a tad long leaving a nasty sharp point sticking out the back side. I don't like sharp pointy things sticking out of the wood so I again brought the Dremel out with its cut-off wheel and ground them flush with the surrounding wood. Here are those sharp points.

With the legs for the front part of the layout complete, I started messing around with setting it up. Using clamps you can actually put this together with one person. You lift a girder and clamp it to one side of the leg. While keeping the leg from collapsing, grab the other girder and clamp it to the other side. Go to the other end, and do the same thing with the second leg set. If all goes well so far, you have a very rickety structure that's just barely hanging together. From that point, you have to set the girder height and then temporarily clamp a longitudinal diagonal brace to start squaring it up. I was all set to make new diagonals and then I remembered that all the previous diagonals were sitting in the other part of the basement with the gusset plates still attached. I was careful when taking this apart for the move so much can be re-installed.

It was getting late and I was getting worn out. I was attempting to run a level from the newly installed rear girder to these old girders to set their height. My foot bumped one of the legs and the whole shebang came crashing down. That was a sign! Quite while you're ahead and I stopped work for the day and went up for dinner. Next time, I'll use the big C-clamps since they have more grip than the quick clamps I was using.

This part of the work goes very fast. It will slow down again when I start installing all those joists and their risers.

Attachments

You must be an engineer! You do very precise work and your layout will be a work of art.![]() By the way, you ought to treat your knees to a pair of Easy-Knee jeans. They have a pocket at the knee that holds a pad in place. Wonderful invention!! (No, I don't work for them.)

By the way, you ought to treat your knees to a pair of Easy-Knee jeans. They have a pocket at the knee that holds a pad in place. Wonderful invention!! (No, I don't work for them.)

Thanks! I'm more a frustrated engineer. Didn't have the math smarts in high school so ended up going to Michigan State to become an industrial designer. That morphed into graduating with an industrial arts education degree where I taught shop classes for seven years after graduation. That morphed into a career in industrial education working up through a series of larger and larger companies. My German sojourn was the result of being the head of training for Henkel at their corporate headquarters in Düsseldorf. But as a model builder and teacher of skills to others, it's in my nature to be precise and a bit obsessive. I do find that working carefully leads to a nice-running, reliable layout. Also, it made it easy to build it in one place, tear it apart, rebuild it in another place and then tear it apart again and build it a third time. Like my career, each time it comes back bigger than before.

As far as the jeans. Most of the work now is going to take place off the floor, but thanks for the lead.

OK, a few days back you asked for opinions on level or raised for the far back track.

I would definitely go with raised despite the extra work.

For a run that long you really don't want it constantly out of view.

Having a mountainside here and there you cut into will make it more realistic as well.

Cuts, tunnels, trestles, all add to the scenic delight of the viewer.