Took longer than 10 min. as Google Android is messed up beyond belief ( I have to use three browsers to do anything, and still limited.) I only use Android because of the price. I'd advise avoiding it if you can. I won't touch the Google engines and disable everything I can from them.... I trust Facebook more (which is about 2/1000ths of an ounce of trust for FB). The fact everyone is still lemming-ing behind these two crap companies is so Orwellistic it's scary.

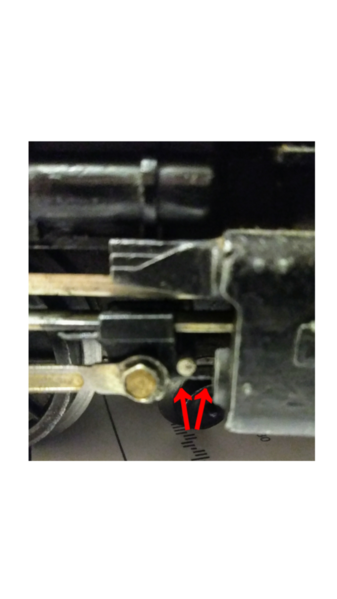

Anyhow, here is the linkage,rods,crossheads etc. for the 2037. (these have seen wheel sets worn out. Mega-hours of running on them. (Note the ridges from wear on the backside of the lower rod )

This may be my last post for a long while fyi (months) ; it's just too frustrating and all parties involved past my fingers, all just point thier fingers at each other. I keep expecting the Family Circus "Not Me" ghost to appear .

I'm tired of spending 3 days a month minimum struggling to perform the simplest of tasks because coders can't keep it right for 30days straight. I just want to read, navigate, and post sometimes. That's it... no shopping, paying, legal BS, or social sites (except this one). I shouldn't have more issues in 2019 than ever, I should have less, and blame Google/Android mostly. (because MS is trying to be Google-II or i-II, and Apple isn't even close to being something I'd consider (my brother budgets a few grand a year just for new i-ware for the family. I cannot. (would not anyhow... far too much $; not worth it) I sure wish MS would walk thier own path again. Copying the others styles just isn't working out, they are just as bad now. (even when I had viruses Windows navigated than the others.)

(e g, the photo was ready 4min after the last post, but browser fun delayed me a half hour, then this small post took over a half hour to type because composing requires "200" corrections of spellwreck program mistakes. No wonder I went from 70 replies a day to 7, eh?).