Progress. Glad to see you back and gradually building up steam.

Thank you, Bill!! The layout is high enough and narrow enough, I can do most wiring sitting on a stool and bending over a little. After 3 weeks of not doing anything after surgery, One of the exercises from my first PT was to sit and bend like tieing my shoe. I can still do it but for short spurts now without pain. 👍🏻

Best wishes on the recovery, Mark.

I find your utilization of space better executed than most with twice the footprint. The limiting of equipment size and weight produces optimum usage of every inch of track plan. What you have successfully wedged into 11 X 11 should serve as an excellent example to all wanting maximum 3 rail enjoyment in a compact space.

WTG, Mark!

Bruce

Thank you very much, Bruce!! It has been a challenge, but worth it.

I was able to get my engines to run nicely over the two switches leading to the long sidings. The only problem was that I had forgotten to make a power connection to the left hand siding. That was quickly remedied, but I didn't have a chance to test it out until last evening.

Now it's time to get on to the next project. Should I wire in the DZ1000 switch machines or the power drops to the AIUs first? I'm thinking the power drops, so I can easily turn off power to sidings that are holding engines not in use, instead of having to lift wires. I can do all that seated on my rolling stool, whereas I need to bend under the layout to get wires connected to some of the DZ1000 drops. That would let my lower back get a little better first.

Attachments

Mark, looks great and I am glad you were able to get your siding wired and working! I don't have an AIU so I can't help you there!![]()

Mark, are you going to use the AIU to control track power to your sidings? I have been considering going this route instead of using traditional toggle switches. My understanding is you should put (if I remember correctly) a 4 amp fuse in line to protect the AIU. I think I read somewhere older AIU's were capable of controlling possibly 10 amps. Correct me if this info is incorrect.

Michael

Thank you, Mike!

Michael, Since I was planning to use AIUs to control the switches, I decided to use the other ports to control power feeds. I bought toggle switches to make a traditional panel to turn track power feeds off. Then I realized I actually have two operating areas, the main one in the center of the layout, and another in the aisle outside the lift-up bridges. What if I wanted to be close to my enginehouse or sidings that are along the aisle and all my toggle switches were on the other side. I could have used two way switches, but decided if I had the DCS remote in hand, I might as well use the AIU ports.

I do not recall reading about in-line fuses when I read up on the AIUs last winter, but most of what I read has been overwritten. ![]() I put TVSs across every track feed at the track end. Yes, in-line fuses make sense. I will have to go back and see what is recommended. Thank you for asking the question.

I put TVSs across every track feed at the track end. Yes, in-line fuses make sense. I will have to go back and see what is recommended. Thank you for asking the question.

I'm pretty sure the AIU ACC ports are only rated for 4 amps. that's probably enough for an engine or two, but certainly not enough for very many incandescent passenger cars; absolutely not enough for a derailment or short.

Thank you, John! I was just looking this up in Barry's book. He recommends the 4-amp in-line fuse like Michael wrote. Barry says you can have the AIU control an external relay that does the actual switching to the track. I have LEDs to install in my passenger cars and caboose.

Mark,

I was going to suggest using the AIU to operate external relays, but apparently Barry beat me to it! You will need a power source to drive the relays. Installing LEDs in your passenger equipment will definitely cut the current draw.

Chris

LVHR

Chris, Thank you very much!! Yes, I had the page in Barry's book bookmarked, but totally forgot about the need for the relays. I have plenty of power supplies, so that won't be the issue. I won't be ready for relays until I get them ordered and they arrive anyway, so it shouldn't be a problem.

Mark, what relays and power source will you use? I haven't decided yet if I am going to go this route or use traditional toggle switches.

Michael

Michael, I’ll have to work on that. I didn’t get to look at relays at all. Yes, I know. I already have the toggle switches. I’ll have to look at it to think which is worth the trouble. 😄

Mark if you are working with DCS and need relay info, call or e-mail me. We are doing relays with AIUs for both turnouts and track power now and can probably tell you what you need and send you a couple of wired relays to start with.

Thanks to Stan a few years ago, we have almost “mastered” the AIU/relay job.

We just reordered a month ago and got a bunch.

I think that you have our information.

Congrats on getting the track wiring completed! Wiring is the one thing I dislike the most about the hobby - ballasting is a close second! lol

-Greg

Thank you Greg and Bill!

Bill, I would be glad to hear from you on how you are doing it. Thank you. I'll send you an email.

Hi Mark,

I'm sure you are receiving lots of good advice on switching track power with an AIU. This is my plan for my layout as well.

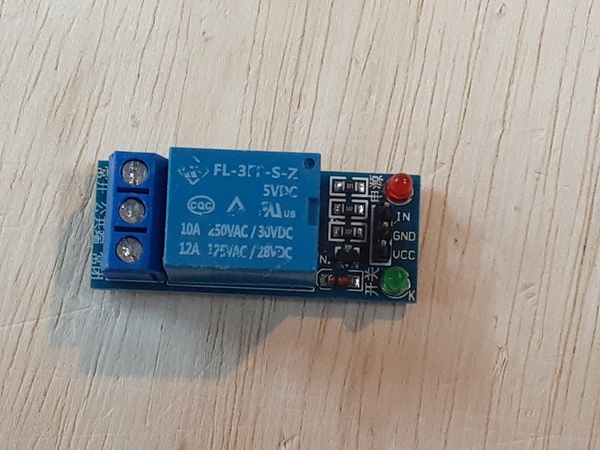

I bought some of these Arduino relays and used a couple in the control wiring for my lift table. Power wiring on the left, low voltage control on the right. The "IN" pin controls the relay contacts by simply grounding it. The AIU would see milliamps in 5vdc at most if the relay power were switched through the AIU, or simply run a ground wire through the AIU contacts to IN. I hope this gives you some ideas.

Attachments

Hi Mark,

Great to hear you are doing good enough to get back to your layout! Fantastic News!

I have been working on the electronics side of my build to try and get as much done before the plywood and homosote block access from the top. My plan which is only in the planning stage is to have AIU interface with a ESP8266 which acts and programs like an arduino, however has WIFI and communications abilities. The esp8266 that is connected to AIU (and located in same area as AIU) will take those commands for switches or track power, command the esp8266 which in turn will send wireless to a remote esp8266 with a relay and the relay will control track power or turnout switching. I have a prototype working without AIU, however AIU is only being used for DCS interface and acts like a toggle switch which my prototype uses successfully. This eliminates wiring from control section to turnouts and also it feeds back the switch position and track power status. I also have it set up for block detection. esp/relay board is around 4 bucks on Aliexpress . This will take sometime for me to complete, however it might be worth the wait if you do not want to have a ton of control wires to every switch and block.

Attachments

Dan and John, thank you! I’m at my 32nd and last PT visit with the heating pads and electrodes almost done. I’ll reply further after I’m home.

I had never hard of Arduino until 2 or 3 years ago here on the Forum. I tried to follow along on a couple threads, and got totally lost. ![]() Bill said he would send me some documentation on how he is doing his AIUs and relays next week, so I will look at that and see what else comes up. I'm open to any idea, and won't be getting to any of it very fast. Since I can get around better now, I still have to get stronger and get some things done before winter.

Bill said he would send me some documentation on how he is doing his AIUs and relays next week, so I will look at that and see what else comes up. I'm open to any idea, and won't be getting to any of it very fast. Since I can get around better now, I still have to get stronger and get some things done before winter.

This afternoon, I worked on installing a grass/leaf catcher for the back of my riding mower. The mower is 10 years old, and I just got the catcher at Lowes last Saturday. Of course, it doesn't exactly fit my older model, but is very close. I had to drill 4 holes into the back of the mower to mount the rack that holds the two bags that catch the leaves. I still have to modify the plastic chute where it attaches to the deck, but figured out what I need to do on Wednesday. That should make leaf gathering easier than in the past.

Mark, this evening I was leafing through Jim Barrett’s book. Chapter 44, ,”Control Layout Lighting with an AIU”, p. 259-264 discusses these issues; including switches. This segment of the hobby makes me feel like I’m taking a math course. No matter how hard I try my brain starts to short out. That’s why I will have to remain in PW mode.

Jay, you have a good point. I picked up on command control in 2012 to make things easier. 😉 I have not bought Jim’s book. I’m trying to make this easy. It may be not that easy. 😄

Glad you're moving better Mark. Odd jobs like the grass catcher are great therapy as well, mentally and physically. I painted rooms after neck and shoulder fixes. That Miaggi guy was on to something. ![]()

Don't let the "arduino" name trip you up. It is simply a set of contacts rated for AC power we use and has a 5 vdc control over the contacts.

How is AREDUINO pronounced?

@Tom Tee posted:How is AREDUINO pronounced?

Arduino (/ɑːrˈdwiːnoʊ/)

@Mark Boyce posted:Jay, you have a good point. I picked up on command control in 2012 to make things easier. 😉 I have not bought Jim’s book. I’m trying to make this easy. It may be not that easy. 😄

Once you figure it out Mark, let us know.......![]()

Bob

Yes Arduino sort of rhymes with my late father-in-law's make believe friend, Guido. ![]() As in "I'll get Guido to squish your face," he would jokingly say.

As in "I'll get Guido to squish your face," he would jokingly say.

Thank you for the encouragement, Dan! If one retired guy can figure it out, another retired guy should be able to. ![]()

Bob, on the other hand, you may be waiting a long time. ![]()

@turkey_hollow_rr posted:Glad you're moving better Mark. Odd jobs like the grass catcher are great therapy as well, mentally and physically. I painted rooms after neck and shoulder fixes. That Miaggi guy was on to something.

Don't let the "Arduino" name trip you up. It is simply a set of contacts rated for AC power we use and has a 5 vdc control over the contacts.

Dan, I forgot to thank you for being glad I am moving around better. You are right about Miyagi. My therapists had told me to try things a little at a time, so I have been doing that. They did give me exercises to continue with, but doing more like you said will help mentally as well as physically. Thank you!

It has been over a month since I last posted here. I have been prewiring AIUs to turn on and off each track block. I chose to follow the method Bill Webb is using. Bill gave me a bunch of photographs and a written description of how he is doing it. I think I have it done right. ![]() Since the AIU relays can't handle the amperage on track sections, Bill used circuit boards with relays that can handle the amperage. The handheld will select one of the accessory channels on an AIU, that contact closure will operate one of the blue relays which will close the circuit to apply power to a track section. That way I can easily turn off power to sidings if I want to leave an engine set there, and it can also be an aid in troubleshooting short or open circuits.

Since the AIU relays can't handle the amperage on track sections, Bill used circuit boards with relays that can handle the amperage. The handheld will select one of the accessory channels on an AIU, that contact closure will operate one of the blue relays which will close the circuit to apply power to a track section. That way I can easily turn off power to sidings if I want to leave an engine set there, and it can also be an aid in troubleshooting short or open circuits.

I have everything wired up except the red and black wires going to the mainline blocks. The red wires will connect to the relay board that has red wires on on side of each contact and the black wires will connect to the black side of the MTH terminal block. Once I move wires, I can move the TIU Fixed Output 1 to the MTH terminal block in the top of the photograph, and should be in business. I'll keep my fingers crossed. Up until now everything on the original setup has been left intact so I can still run trains. Once I get that working, I'll finish prewiring the other two AIUs for the sidings which are powered by Fixed Output 2. DZ1000 connections will come later.

Attachments

Mark,

Your wiring looks fantastic! I love the neat job and how all the wires flow. Glad you are feeling good enough to get back to more "normal" layout work. I am curious about your relay setup for switching track power. I might have to get the info from you on what you used and how it is wired up. I still haven't decided if I want to use the AIU's to switch track power or just use convetional toggle switches. Are you only switching power on sidings or on sections of your mainline as well? Looks like a neat setup and really well executed. Keep up the great work!

Michael

That's a beautiful job ya done there Mark! I never thought of using an AIU like this. I like the idea!

Bill and Michael, Thank you. I don't work well with the thinner gauge wire anymore. I think that is #18, but I have had the spools for 35 years, and the labels are gone, and I didn't bother putting the wire under the magnifier. Yes that #14 wire really does make for some nice curves. You have to let the first run find it's own way, then all the rest follow along.

I knew folks were using the AIU accessory ports to power track blocks, but didn't know how they were doing it. Bill Webb offered to show me what he was doing, and it made sense. I have 15 blocks for sidings, and only 7 for the mainline. I decided I might as well setup the whole mainline the same way to isolate troubles. I had bought toggle switches to make a panel, but decided since I was going to use AIUs to control the switches, I might as well try them to power blocks as well. There is one caveat; both sides of my power boards are filling up quickly. I still haven't given any thought to building lighting, uncouplers, etc. ![]()

Attachments

Nice work Mark. If I ever go to a full DCS system, this is a nice clean way to do power control.

Keep making progress. ![]()

Bob

Beautiful work, Mark!

Dennis: mine looks more like yours than Mark's. I suspect a lot of us are in that boat . . . uh, nest.

Thank you, Steve! I learned a lot of wiring tricks working as a technician on controls at the power company. Many don’t come into play on a layout, but some do. Their electricians produced nothing less than works of art. When I was laid off and went to the telephone company at the age of 40, I was appalled at what some of our wiring was like at customer locations. Some customers had pitiful wiring as well. I’ve seen computer rooms that look not far from Dennis’ ‘abstract art’.

Neat wiring, tagging, and documentation up front makes troubleshooting much easier. I have some more tagging to do plus make new drawings for this upgrade.

Mark, that looks great! Do you still have to use the Gunrunner John's watch dog thing with the AIU's?

Mark get out those red and green pencils for the wiring schematic updates. LOL

Mark, you just have to sort your AIU's. Some of them had 10A relays, others have 5A relays. We had a long discussion about this some time back on OGR. I was surprised to find different ratings on the relays, and I certainly don't understand why they want with 5A relays.