it's a frankenbilt !!!!

The one and only! It's really turning into a lot of work, seems like every little thing needs some attention so it fits right or looks right.

Thanks Dave. I may look at doing that. I only have a couple of sets of 6 wheel trucks and they belong on some tenders. I keep watching for them but dang, they get bid up really high really quickly. I was also thinking of cutting up some prewar trucks and stretching the wheelbase out some. Would be a bit of pain though. I'll probably do one just to see if I can make one that looks good.

that's why I started to make my own, the original six wheeled truck are pricey. all you need are regular four Prewar tucks, take off one set of journal covers, slip the two trucks together, and use one pair of journal covers to hold the two truck together. I did my first set a couple years ago and they are holding up fine.

Dennis Holler posted:Few more shots of it up on the highline, had to move some stored locos

I'm not sure if the 600 series Pullmans are tall enough, the body shell is about 1/8" shorter than the 613 series cars. It's hard to get a good visual without the roof on the stretched car, but do you think it will be tall enough to fit in with the loco and tender? Also, I think I'll tuck the tender trucks in front and rear just a tad.

Hey Dennis - tell me about that K4 on the top shelf - is it a scale O engine? 2 Rail? Looks like you could use a lead and trailing truck.

Jim

Hi Jim,

It's a Scale-craft K4 built from a kit (1930's). I have two, one built and one not. I have the missing pieces to the black one. I took them off when I was trying to get the mechanism to run smoothly. It really needs to be rebuilt more than anything. I keep it on the shelf so it doesn't get broken more lol. Plus I like it and the Scale-craft reefers behind it. Here is the other one I have beside a Legacy Lionel K4.

And the Black one with a Williams Brass K4.

Attachments

A lot of the ones I've seen don't look right because the builder did not fit the belpair wrapper sheet correctly. Most sit to high, very high. I keep waiting for a cheap Scale-craft Hudson to turn up but cheap and Scale-craft Hudson don't seem to go together.

Did a little more work on the tender. I finally have both tender trucks the way I think I want them. I moved both in about 1/4" from the ends so the trucks aren't poking out.

I also made a new longer coupler bar for the six wheel truck so the coupler would articulate properly. I even tested it behind a stock 265E with a 613 behind and it ran through the layout and tracked perfectly. I have a few more details on the tender and it will be ready for bondo and paint...

Attachments

Dennis love your post. Talk about being creative? This looks great, Lionel should of made this when it first came out![]()

Dennis Holler posted:

A four wheel lead truck might be a little tight!

I like the boiler bands. The center one covers the seam, great thinking.

Would a 2025 motor with the Baldwin wheels fit? Those Baldwin wheels would really make it.

Jim Waterman posted:Dennis Holler posted:A four wheel lead truck might be a little tight!

Yeah, I now wish I had stretched it just a bit more. It needs more overhang in the back, ie the cab is really short once you stretch the boiler. I do still have the other two pieces from the shells I made this one from...I'll get this one running and maybe that will be anew project.

RonH posted:I like the boiler bands. The center one covers the seam, great thinking.

Would a 2025 motor with the Baldwin wheels fit? Those Baldwin wheels would really make it.

Thanks Ron, yes a Baldwin wheel motor would fit. I have been setting it up for a magna-traction motor from a late 2025/675, but the earlier Baldwin motor would also fit. I really like those wheels too, but wasn't the Hudson typically an Alco product?

Dennis Holler posted:RonH posted:I like the boiler bands. The center one covers the seam, great thinking.

Would a 2025 motor with the Baldwin wheels fit? Those Baldwin wheels would really make it.

Thanks Ron, yes a Baldwin wheel motor would fit. I have been setting it up for a magna-traction motor from a late 2025/675, but the earlier Baldwin motor would also fit. I really like those wheels too, but wasn't the Hudson typically an Alco product?

Yeh, but those wheels do look good.

I agree, but a repro set of those wheels is about 100 Euro ![]() plus axles, gears, etc...from what I can see even the 4 wheel Marklin motors are going for 100-150 Euro on German ebay... it just nutZ! Ritter even lists a set of repro side rods at 175 euro per side. I'm hoping to buy some originals off the bay...

plus axles, gears, etc...from what I can see even the 4 wheel Marklin motors are going for 100-150 Euro on German ebay... it just nutZ! Ritter even lists a set of repro side rods at 175 euro per side. I'm hoping to buy some originals off the bay...

looking good Dennis

Dennis,

Real nice engineering and sheet metal work to customize everything.

Steamer,

Dave yours stuff is just fantastic also!

Where do you guys find the time to accomplish this stuff, I am retired and do not have the time you guys make for doing these neat custom jobs.

PCRR/Dave

Thanks Dave, I feel like I never get anything done. I started this project last spring! My biggest problem is that I start way too many projects and end up never finishing or it takes forever to finish. It is fun to post this stuff up here though, it helps me remember what I did and I hope people get some entertainment out of it.

Dennis - true labor of love here.

One hint - cardboard bearings don't hold up too well (little joke)

An idea - instead of making whole new plates, can you 'add' metal to the existing 6 wheel sideframes to match the mounting? The really hard work is getting the holes for the bearings drilled precisely, and then there are those little slots for the fiber 3rd rail mount, and the motor cutouts, you get the idea. Might want to lay the 6 wheel sideframes over your cardboard mockups and see what is needed.

Jim

You are certainly right Jim, I think it's going to be a pain. I split the old frames so I could use them to lay it out. I've got the new frames rough cut out and plan to drill alignment holes and put them together with parts of the other frames and then file the perimiter to match the combination of the old frames. I'll locate the 6 wheel front axle at the 4 wheel motor front axle. So all the "motor" locating points will be from the 6 wheel. Only the ends will be from the 4 wheel. Then I want to use transfer punches to mark the new holes. I completely understand this is a real delicate deal and may not work but I've always been so intriged by the loco conversion book by Henniger that Ihave to try it! 😳 Just can't get away from it. I want to do the same thing for the P5A I want to build. That wood P5 I have can be the worm drive like you did with the channel. Btw, Istill think that is a way cool setup you did. It would work good here too. I guess it's the tinkerer in me, can't do it the easy way! If this doesn't work, I can cut and add the ends to the 6 wheel motor. Another option is I've found a couple of sources in the UK that laser cut live steamer frames and one will cut what you send him in a cad file ao that is a possibility too.

A wooden P5!? wow I need to see a picture of that. All I have is a stinkin Gold O-1. I made up some drivers for a Std Gauge GG1, might work for a SG P5. They are 1.8" diameter, blackened machined steel. Really nice.

Attachments

Jim, I'm sorry, I meant wood O1 not P5, my bad. The plan is to create one of each tinplate style though. Kind of an O gauge version of the standard gauge O1 in the old Model Builder.

Dennis,

Wow! Not sure how I missed this whole topic over the last 2 years! Very cool. Looking forward to how you progress on this. The shell is really looking very sharp. You and Dave are quite the metalcrafters. I guess you may not use them in the finished piece, but I do like the looks of those red-spoked drivers!

Tom

Thanks Tom, it's been on again off again unfortunately but it is coming along. I liked the red rivers too, but they were from my Marklin HR66 920 and I ain't robbing that loco! In the end I should have stretched it just a bit more and then it would easily accommodate more scale sized drivers. If I ever do one again, I won't make the same mistake! ![]()

it's saved me some grief by loosing the e unit when I'm doing a custom. keep plugging away Dennis!

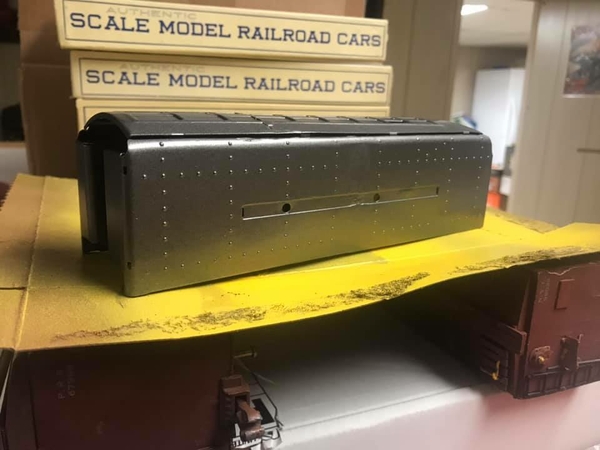

Been a long time but I pulled this thing out and took some paint to the tender and will try to get it put together. Rustoleum Charcol Metallic, not too bad, def not a good Gunmetal but still not to bad.

Attachments

Any update on the loco - figure out the mechanism? Is a 2025/675 mechanism too long? Nice early ones with the chrome rim drivers.

Here are a few more with the trucks installed. I still need to put some clear coat on it and install the trim though. Jim, since I have a bunch of the Baldwin disc motors and parts of those motors, that would probably be the easiest path.