Tom, sadly that video didn't happen. I'm not sure what happened with the phone, but there was no video. Spoiled the whole joke! ![]()

gunrunnerjohn posted:Thanks guys, I'm looking forward to having real track on this and being able to put together some real consists.

Is FasTrack fake?

Let's just say it's not real enough for me Greg. I've used it for years, I'm looking forward to being able to hear the sound systems of my locomotives and not the wheels on the echo chamber. ![]()

2I can see the lure of some of the Atlas, Ross, and Gargraves realistic looking track. I like the Fastrack for several reasons, but I'm sure it makes some more noise. On the 1/4 inch indoor/outdoor carpet, it's quiet enough for me...it's quietest if you run prototypical speeds.

The quietest I ever heard was on tubular at a train meet. I think it was 027.

John, really enjoying your work. Looking forward to seeing you get you real track down.

thanks for sharing.

Rich, you're not the only one, can't wait to see something run on the the full layout, that will be very cool! ![]()

All restocked John. It might be tomorrow before the website is updated.

FWIW, if anyone has a Legacy locomotive and needs the conversion jumper for the standard YLB to the RS-Lite board, I do have a few, drop me an email.

Not enough room on the right side?

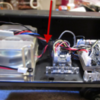

It should fit right here.

You could also simply splice a couple of inches into the red and black wires if you want to extend it farther. You'll have to do the same thing with the standard YLB with the battery clip.

Attachments

I get the connector assemblies pre-cut, that's why they're that length. Also, I truthfully didn't think there would be that much demand for a really long wire. Maybe I need to offer "extension" cables. ![]()

John Rowlen posted:I have a beater VL Big Boy #4014 I used when I designed my layout.

This has to be a first, at least for me! I don't have many "beater" $2,000 locomotives! ![]()

![]()

I feel better now, I was having a problem with the "beater" designation! ![]()

![]()

John,

I have installed the YLB 10500 or 10510 in 30 steam engines so far. There is no room in the Vision Line Big Boy Tender for a YLB. I will add a double pick-up roller to my tender. At very slow speeds, the Big Boy Coal tender drops sound on a Atlas #5 Double Slip Switch. Some of my smaller engines have tethers, so they won't need batteries. I have twelve steam engines with tethers or no room for batteries. I evidently miss-counted steam engines initially. The new total is 42. And they are all completed.

Thanks again for a solution that has solved the biggest issue on my model railroad.

I will be deleting my posts in this thread in order to keep it on topic. Your layout is going to be excellent. I look forward to following the thread.

Sincerely, John Rowlen

Those guys keep selling that stuff, I'm going to have to talk to them about it! ![]() I'll see what I can do about getting them restocked early next week. They had 15 of them on Wed, someone keeps buying them.

I'll see what I can do about getting them restocked early next week. They had 15 of them on Wed, someone keeps buying them. ![]()

John,

I put "the beater" on the tracks and got all features working except the coal.

It was a bright spot in my day after Katie said Lionel had no replacement parts for the missing cowcatcher and coupler on my AC-12 Southern Pacific #4294 that came back from Lionel Service with them missing. How much skill does it take to put all the parts back on an engine after it has been worked on?

Sincerely, John Rowlen

Attachments

John,

Thank you for delivering more YLB Batteries to Henning's Trains. I have finished the 30 steam engines and will see if any diesels have issues with the Atlas O switches. It is strange that an Atlas O Trainman U23b, with only two pick-up rollers, stalls on the Atlas O #5 Double Crossover switches. Atlas needs to put four pick-up rollers on all of their engines. The Master line engines are fine with four pick-up rollers.

Thank you again.

Sincerely, John Rowlen

You keep buying, and I'll keep making. ![]()

How is the plywood inventory restocking schedule coming along?

I'm hoping to actually get it this week. We've had some non-train related family stuff that has consumed a lot of time, and that seems to keep bumping my trip for plywood back. ![]()

A really tiny step, I finally got the additional wood to finish the upper level and to build the track inclines. At least it's in the house! ![]()

The drop cloths are just to keep me from whacking a shin on the protruding 5 x 5 piece. ![]()

Attachments

Tiny steps help get you to the destination John!! ![]()

I see something in the distant fog... It's a working layout! ![]()

If you were to build a fair replica of your house, including your new train room, then build a replica of your new layout (a static graphic model would be fine) in the appropriate room, you could say that your "new layout finally getting a train room".

This is not a new idea, of course; maybe even mentioned in the last 22 Forum pages.

Life has intervened in my construction plans and I'm currently working on finishing our loft that used to be storage. Since it needed climate control, I went with the ductless heatpump up there. For a modest extra sum, the ductless outdoor units will handle two indoor units. That being the case, my trainroom got upgraded climate control. 18,000 BTU of heat or A/C on tap now.

Attachments

Looks good John. Those ductless splits are great units.

GRJ,

I just saw that unit on Amazon for $1,100 earlier this week. Did you find a better price elsewhere?

On a scale of 1-10, with 10 being a real pain in the doopa, how hard was it to install?

SantaFeJim posted:GRJ,

I just saw that unit on Amazon for $1,100 earlier this week. Did you find a better price elsewhere?

On a scale of 1-10, with 10 being a real pain in the doopa, how hard was it to install?

No way I'd try to install this, and after seeing the process, I'm glad I didn't! The units themselves are not that expensive, but it takes considerable labor to install them. One of them, the one on the 3rd floor, has about 60 feet of refrigerant lines going to it. Just watching the process convinces me that is not a job for a novice. You also have to be EPA licensed to buy refrigerant of any type. Add to that the tools you need for the installation, a boatload of brass hardware, vacuum pump, coolant pressure gauges, etc., it's not worth it to attempt these installs on your own.

To answer the question, it was easy, I use the telephone as my primary installation tool. ![]()

gunrunnerjohn posted:SantaFeJim posted:GRJ,

On a scale of 1-10, with 10 being a real pain in the doopa, how hard was it to install?

To answer the question, it was easy, I use the telephone as my primary installation tool.

Nuff said. Thank you.

Suffice to say, it took three and part of the time four guys two days to install the attic and trainroom units, as well as the outside unit. They had ladders, hardware, an extensive assortment of hardware, cable runs for up the wall, etc. It took two of these guys one day to install the main level gas furnace and A/C unit! A big part of the install is connecting the two inside units with the outside units. Then there's the 50A circuit to the outside unit that has about 80-90 feet of cable back to the power panel, the drains from the two units, etc.

There are lots of projects that a homeowner can reasonably tackle, this isn't one of them, at least IMO.

My whole house has new heat and A/C for all levels, I should be good for many years to come.

Attachments

They are certainly nice units! I agree the refrigerant lines, etc. would be a project for the professionals. Certainly not for us who have trouble lifting and carying even if we knew what we were doing! ![]()

Mark, there's also the minor inconvenience of having to be EPA certified to handle refrigerant. ![]()

The same as me not letting these guys design a circuit for me, I wouldn't try to do their job. That's not to say I don't understand the elements that go into the job, but they arrive with two large trucks full of equipment and tools. By the time I buy all the equipment and tools needed to do the job, I'd have already paid for professional installation. Since I'd only get to use all the equipment and tools once for the most part, it doesn't seem to make sense.

Very nice, neat job. Worth every penny John. He's right guys- leave it to the pros.

We've been installing these on my campus for many years. They are very efficient. Most have variable speed compressors and only use power as necessary. Ductless splits have been around a long time. Only been in the States for about 10-15 years.

Bob

I remember seeing these units in Europe in the 2000-2007 and wondering why I'd never seen them in the US. In the last few years, they've been popping up everywhere. It so happened that my particular situation lends itself to the dual head unit perfectly, and having individual climate control for the added areas is way better than trying to tie them into the main system.

Yep- ductwork takes up precious train space.

Can't have that now, can we....![]()

John:

I had an old wall unit for the garage shop replaced with a mini-split about 6 months ago. The installers (Goettle) did a great job. They removed the old unit, plugged and patched in the hole (quite large) and since the hole was there installed all wires and hose inside the wall, then installed the handler high up towards the ceiling out of the way. The unit plus installation was not cheap but with its quality and efficiency bills will be less expensive from now on.

Joe

Added photo - the patch work for the old unit is just behind the hand cart.

Attachments

gunrunnerjohn posted:Mark, there's also the minor inconvenience of having to be EPA certified to handle refrigerant.

Yes indeed, John!! ![]()

Looking good John. Temperature control is an important factor. The techs did a nice clean job.

Andy

Yep, they were pretty professional, I'm hoping that solves one problem I might have, comfort. ![]()

Had Mitsubishi setup with 5 wall units hooked up to a big unit outside. Have hot water heat on the first floor and forced air on the second floor. The spit system was about the best way to go. Was more money but think it was worth it. Had them put a unit in the train room. They all have AC heat and a dry setting mode to dehumidify. Took 4 guys about a day and a half to install. Just love it only run it in the rooms being used at the time. Supper quiet system can't really hear the outside unit running. Not like the noise the compressor for the second floor AC system makes. Yea they were talking tear out the ceiling in the train room to install ducts for a forced air system for the first floor. It would be about half the price as a split system for equipment and install. I really did not want to take all the trains and stuff out so they could run ducts. Not to mention the mess taking out the ceiling. Anyway a great system.