The yard is done!

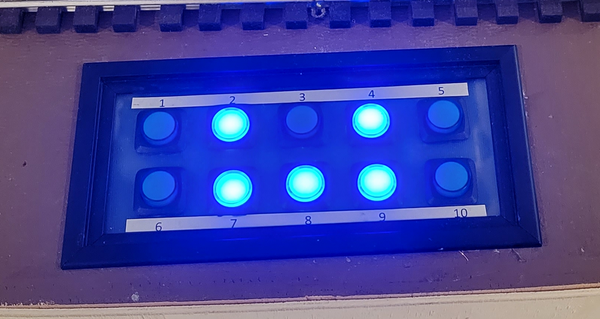

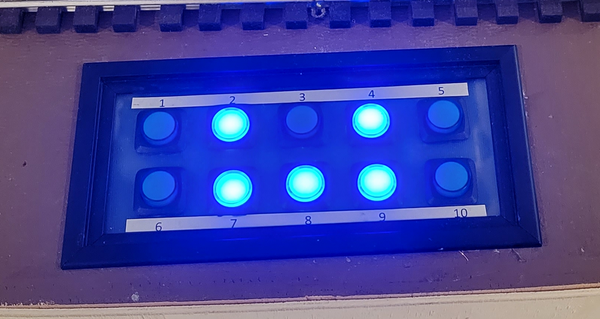

Time for a party! Got my switch panel installed, wired all the tracks, and tested all the routes and switching.

Time for a party! Got my switch panel installed, wired all the tracks, and tested all the routes and switching.

One little glitch surfaced that I overlooked when laying track. The Ross #202 yard switches that I used I "thought" I ordered pre-wired, but in looking at my invoice, I got the plain bare switch. So, power was not carried through the switch. In truth, that was probably a good thing in retrospect, I got to decide how the crossover to the next track was powered. However, I conveniently forgot about power until I was testing and noticed that the power stopped as the switches!  That little oversight was corrected and now all is well.

That little oversight was corrected and now all is well.

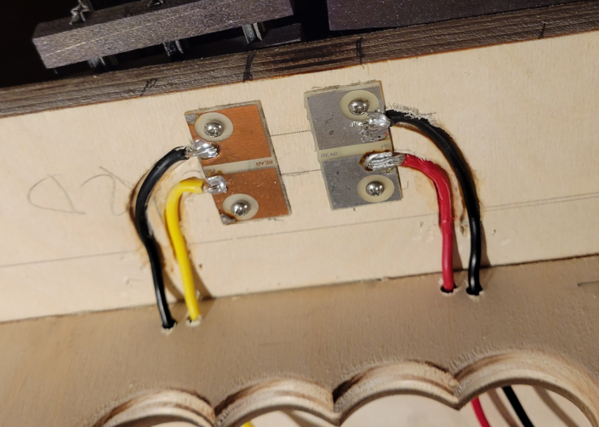

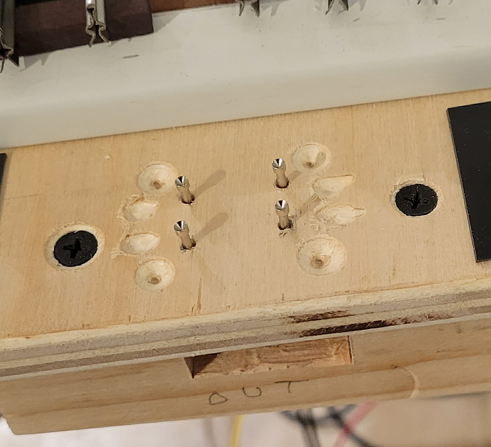

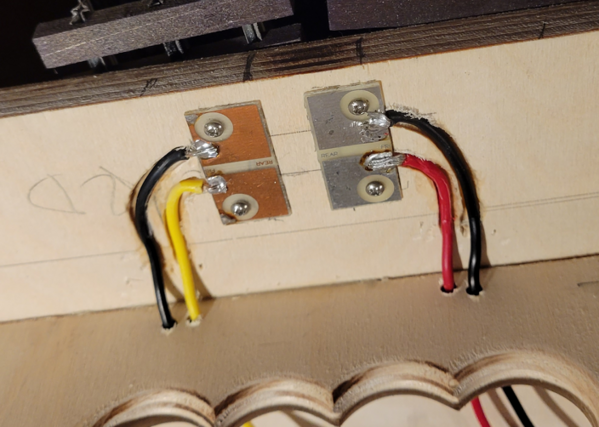

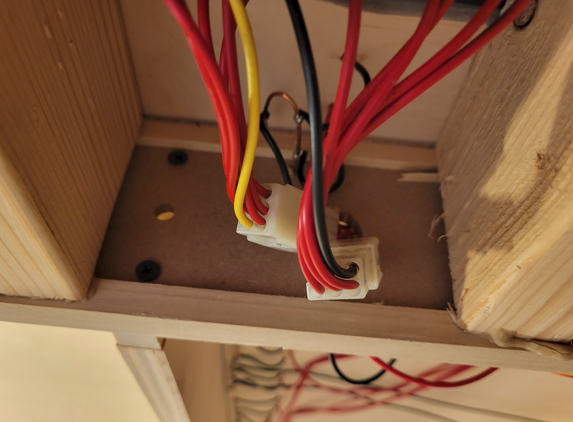

I embedded a little lighted push-button toggle panel into the yard to power each track individually. Given my track record with switches lately, I added connectors at the panel so I can remove it if necessary to replace a switch!