OK, I had a crazy idea! I was looking at possible track plans, and one thing that I don't have is space for stuff like a reverse loop in O72 or larger. I'm thinking, while I'm sure I can do something nice in this space, would it be crazy to add a little surface area?

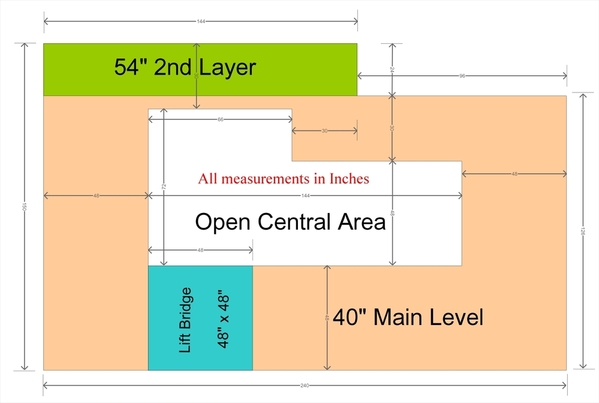

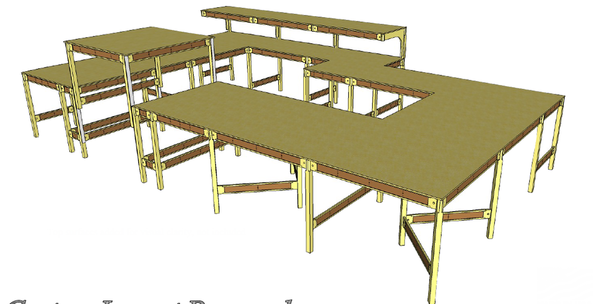

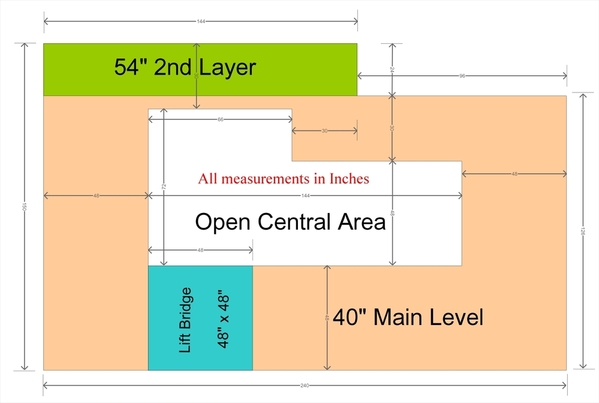

Here's what I have, but the liftgate has been shifted 30" to the right in my current plan, it just didn't change any surface area.

I'm thinking maybe I should close four feet of the right hand opening and end up with this. That gives me a 10.5' x 8' end that's available for track. I know I'll have some issues getting to the middle, but I guess I'll have to live with that for the flexibility of having more area to work with. The good thing is, I have all the benchwork pieces to do this already.

I'm also planning on a little corner cut to allow more space at the back for the trains to make that curve.

So, what do you think? Crazy? Cool? Must have? My one concern, obviously, is access to the center of the table.

![]()