Very nice. Thank you for sharing pictures of your marvelous layout.

@NJCJOE posted:So, when I came up with the design for the new layout, I wanted a way to create some cohesiveness between the O gauge and standard gauge portions of the layout, especially since the O gauge crosses directly over the standard gauge. I decided to make the scenery on both layouts similar, realistic and detailed. You can see my intent by the previous post about the river construction.

I decided one way to add some realism to the standard gauge layout was through the use of ballast. Not many people ballast their standard gauge track. During my decision on what to use for ballast, I realized something I always knew but never really had to contend with because my previous layouts were all toy train like layouts. Standard gauge is not set to any scale. Just look at the size between a State set coach verses a Blue Comet coach.

This was something that really challenged me when it came to finding the right ballast. There are some companies that make G scale ballast, but for the amount I needed it would be cost prohibitive. Turkey grit was another possibility. However, all the bags I found locally were opaque, not allowing me to see what it looked like and a lot of poultry grit is pinkish to attract the birds, not something I wanted.

I went into Home Depot and found a bag of stone used for concrete aggregate. There was one bag ripped open on the shelf and even though the stone varied in size, it looked like it would work. I bought a bag and brought it home. The stone was very dirty and had to be rinsed off multiple times. I then took a small section of tack mounted on some scrap Homasote and glued the ballast in place. I was not happy with the result. The stone sizes varied too much for my taste.

Next, I headed over to a local stone center and found some 1B grey stone, which looked like it would work. I purchased two five gallon buckets of the stone. I had to wash this stone as well. After looking it over, I discovered it was the same stone I bought from Home Depot in the bag.

At this point I started to think maybe ballast for the standard gauge is not a good choice. I then came up with the idea of sifting out the small fines and the large stones to see if I could be left with a stone size I was happy with.

This turned out to be a few step process. First, the stone had to be washed. I did this over a piece of aluminum window screen. This flushed out all the fines and stone dust.

I then dumped the clean stone into a sifting pan I bought from Amazon. I came with different size sieves. I selected a size and sifted the large stones out.

After sifting the two buckets and one bag of stone, I was left with about two five gallon pails worth of stone.

The stone was then spread out on a tarp to dry for a few days. I was pretty happy with the ballast and figured it would create the illusion I was looking for, so that is what I went with.

The ballast was poured over the track and sides with a small garden shovel. I then used a paint brush to level it out and get it into place. The ballast was sprayed with wet water (water with a few drops of liquid soap). I then mixed Elmer’s Glue-All glue and water at a ratio of 1 part glue to 3 parts water and poured it over the ballast. It took two applications of the glue, a few days apart, in order to completely glue everything in place. This was due to the size of the ballast and the large voids between pieces. Make sure you use Elmer’s Glue-All and not their School Glue. They are not the same. I used the School Glue on the test piece and could not keep the glue and water mixed.

So, now all the track is ballasted. I used about eight to nine gallons of stone on the layout. I still have about 1-1/2 gallons left over. The total coast for the stone material……..about $16. It took some time and work, but I like the end result.

You are doing a fantastic job! Would love to come see it in person some day!

You're welcome anytime Sean.

12/23/22 - Not too much has been done recently. Just running trains to make sure everything is working properly before I start the O gauge portion of the layout come the new year.

I did do a little scenery and detail work around the station. It's amazing how sometimes little changes can make a big difference.

MERRY CHRISTMAS

Attachments

Hi Joe,

Merry Christmas and Happy New year to you and Chris.

The layout is coming along beautifully !

Alex

Joe, The layout is a work of art and keeps getting better. The entire train room and railroad collection is equally impressive!

A true inspiration. Thank you for sharing it with everyone here on the forum. Merry Christmas and Best Wishes in the upcoming year, Rick

NJCJOE, Joe, the red “Mikes Diner” is really a great idea, possibly it’s a standard gauge passenger car body and it makes a good focal point on your awesome layout. To me, tinplate trains and accessories are uniquely nostalgic and make a model railroad colorful and fun to view. Your layout is a work of art. Merry Christmas and Happy Railroading Everyone

Joe, you’ve made some nice additions recently. Also important to make sure everything runs properly too.

Andy

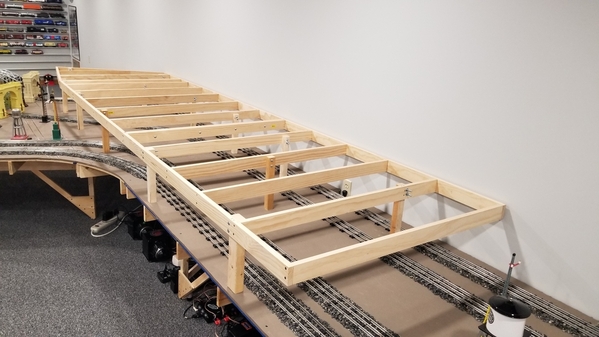

1/31/23 - The O gauge portion of the layout has been started. ![]() I built the section that goes over the standard gauge layout. This section measures 14'-3" by 3'-7". I constructed this bench work in a box style frame using 1"x3" lumber. The joists are approximately 12" o.c. I built it this way to minimize the O gauge layout height, while providing sufficient clearance for the standard gauge trains. The floor to top of bench work height is approximately 36-1/2". Track risers, roadbed and track will increase this height accordingly.

I built the section that goes over the standard gauge layout. This section measures 14'-3" by 3'-7". I constructed this bench work in a box style frame using 1"x3" lumber. The joists are approximately 12" o.c. I built it this way to minimize the O gauge layout height, while providing sufficient clearance for the standard gauge trains. The floor to top of bench work height is approximately 36-1/2". Track risers, roadbed and track will increase this height accordingly.

I installed a bunch of 2"x2" and some 2"x3" legs to support the bench work. A screw was installed into the bottom of each leg from under the standard gauge layout to securely anchor it. There is about 8-1/2" of clearance from the top of the standard gauge track to the bottom of this bench work. Hopefully in the next couple of weeks construction will start on the remaining bench work sections. ![]()

Attachments

Looks great Joe! I have planned something similar. I look forward to your updates. Your train room is fantastic!!!

Bob

The continuation of a spectacular train room. Looks great Joe.

Bob

Wow, @NJCJOE, I really like your carpentry work and the grid addition added for your O gauge trains. Your empire is so amazing and this will be the icing on the cake. I think you have an awesome train room and with Tinplate bright colors, your accessories and bridges, signs, it’s uniquely beautiful. I would imagine your Standard gauge and O gauge are mostly Tinplate, so it’s going to be so colorful and you are the Designer. Thank you for the updates and keep pictures coming. Happy Railroading Everyone

Joe, that benchwork looks sturdy enough to hold a real GG1. Nice job!!

Looking great Joe! I really like how you did the ballast.

Looks great Joe! You have a nice warm inviting room with as you can tell an Amazing layout to enjoy!

very nice

Looks good, Joe - 12" o.c. will certainly provide lots of strength.

Is the rear rail screwed into the wall or does it float ?

I noticed you didn't pre-drill wiring holes in the cross-members. How will the wiring be run ?

@Richie C. the rear rail is not screwed to the wall. There is a slight gap there. I did the same thing with the standard gauge layout. Some people feel attaching to the wall creates more mass and lessens noise, others feel it generates more noise up through the wall. I decided to let it float.

The wiring will either be run down the center underneath through pipe hangers like I did for the standard gauge, except smaller (see photo). Or, I may run the wiring under the standard gauge and pop up to the O gauge where needed.

Attachments

@NJCJOE posted:@Richie C. the rear rail is not screwed to the wall. There is a slight gap there. I did the same thing with the standard gauge layout. Some people feel attaching to the wall creates more mass and lessens noise, others feel it generates more noise up through the wall. I decided to let it float.

The wiring will either be run down the center underneath through pipe hangers like I did for the standard gauge, except smaller (see photo). Or, I may run the wiring under the standard gauge and pop up to the O gauge where needed.

I think you're right about letting the rear rail float and the pipe hangers are a nice touch.

Looks great!

Joe, excellent benchwork. I did something similar to you with the pipe hangers in certain places on my layout. Quick and easy to use. Lots of clearance between the standard and O gauge too, well done.

Andy

@NJCJOE posted:

I use the pipe / conduit holders as well. I usually leave one side unscrewed so I can run the wire and then slip it in. It's a good solution for hanging wire though regardless of 1 or 2 screws..

@NJCJOE posted:@Richie C. the rear rail is not screwed to the wall. There is a slight gap there. I did the same thing with the standard gauge layout. Some people feel attaching to the wall creates more mass and lessens noise, others feel it generates more noise up through the wall. I decided to let it float.

The wiring will either be run down the center underneath through pipe hangers like I did for the standard gauge, except smaller (see photo). Or, I may run the wiring under the standard gauge and pop up to the O gauge where needed.

I like your benchwork - fully adequate without waste or needless expense. I use the conduit hangers too - a cheap and easy way to keep the wiring neat. My first reaction when seeing that picture is "did I post a view under my layout?".

My tip re the conduit hangers... do the initial installation with only one screw, and leave it slightly loose - makes it easier to install the wires. After the wiring is done, install the second screw and tighten both of them.

The conduit hangers are a great alternative to drilling holes in the joists. And as members have stated above, leaving one screw out allows the wires to be tucked in the hangers without guiding them through.

Joe,

First of all, cool new profile photo. Secondly, this looks like a great start to the second part of the your layout. Generally speaking, I like how you have taken us through each phase of your new layout, starting with the beautiful room it's located in. It has been very exciting and educational to watch. My mind can't help but wonder, where will it be at this same time next year. Keep the wonderful work coming.

Dave

Thanks Dave.

It's funny you say that about where the layout progress will be a year from now. Sometimes I feel the progress is moving along slowly. I then have to remind myself that I only started the layout a year ago. So I'm happy with what I have accomplished so far.

BTW, I just back from the lumber yard.......so stay tuned. ![]()

It’s looking great, Joe! You are moving at a good pace.

@NJCJOE posted:It's funny you say that about where the layout progress will be a year from now. Sometimes I feel the progress is moving along slowly. I then have to remind myself that I only started the layout a year ago. So I'm happy with what I have accomplished so far.

For the record, your pace kicks my pace's ***. ![]()

Steven J. Serenska

@Serenska posted:For the record, your pace kicks my pace's ***.

Steven J. Serenska

Mine too! 😄

How long is your O gauge layout going to be ? How many loops ?

![]() Joe you are killing it'.. One heck of a train room, and layouts to match'.. Impeccable craftsmanship showing crisp, clean work'.. Time flies, and you've accomplished a great deal in a years time'...

Joe you are killing it'.. One heck of a train room, and layouts to match'.. Impeccable craftsmanship showing crisp, clean work'.. Time flies, and you've accomplished a great deal in a years time'...

Best, QG

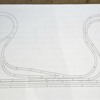

@Frank Ranzino posted:How long is your O gauge layout going to be ? How many loops ?

Frank,

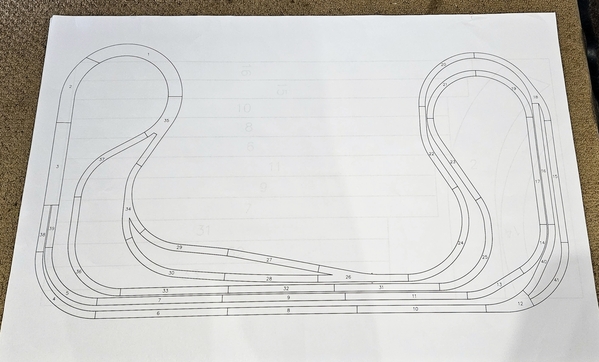

Here is a plan of the layout. The red is the standard gauge and the green is the O gauge.

Attachments

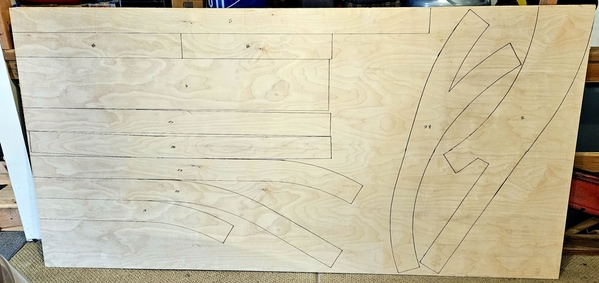

Picked up more lumber yesterday. I had made a drawing of the layout framing showing all lengths and angles, so I spent a couple hours marking up all the boards.

I then set up my saw outside and made all the cuts. Now I have a big puzzle to put together. ![]()

Attachments

Joe, I enjoy building the framework as much as building the layout. Yours is looking great.

2/11/23 - I have about 95% of the O gauge bench work framed up. I still have to frame a low area for a trestle section and add some additional joists and extra leg on the other island. All of the O gauge and standard gauge sections have been connected together with screwed blocking, basically making the whole layout one solid piece. Top of the O gauge joists is set about 36-1/2" above the floor. The O gauge track will be installed over the open grid using strips of plywood road bed and risers. That will be a whole new learning curve for me as I have never done that before. ![]()

Fabricating L-girders and leg assemblies in the shop.

Assembly in the train room.

Everything buttoned up in place.

Attachments

Looking Good Joe!

When's train night???

Come down whenever you want. ![]()

Hi Joe,

Everything is looking great and you're making great progress. I used conduit hangers too, makes it a lot easier.

Alex

@NJCJOE posted:2/11/23 - I have about 95% of the O gauge bench work framed up. I still have to frame a low area for a trestle section and add some additional joists and extra leg on the other island. All of the O gauge and standard gauge sections have been connected together with screwed blocking, basically making the whole layout one solid piece. Top of the O gauge joists is set about 36-1/2" above the floor. The O gauge track will be installed over the open grid using strips of plywood road bed and risers. That will be a whole new learning curve for me as I have never done that before.

Fabricating L-girders and leg assemblies in the shop.

Assembly in the train room.

Everything buttoned up in place.

Great work, NJCJOE.

It's fantastic that you retain the ability to run trains while, it looks like, STOCKERTOWN is doubling in size.

Looking forward to more updates

Gotta keep the railroad running to deliver supplies for the town expansion. ![]()

Joe, the benchwork for the O gauge looks great! That is a neat design to have the two layouts overlap each other like that. I don't think I would have ever thought of it.

@Mark Boyce posted:Joe, the benchwork for the O gauge looks great! That is a neat design to have the two layouts overlap each other like that. I don't think I would have ever thought of it.

It helps to have a room the size of a bowling alley Mark. Not like you and me.....![]()

@RSJB18 posted:It helps to have a room the size of a bowling alley Mark. Not like you and me.....

Bob, I was going to comment about the large room, but I had when Joe was first adding his railroadiana, so I didn’t this time. 😄

Joe, the benchwork is nice, neat, and built well. That’s an advantage of L-girder that it’s quick, easy to build, and is solid. Nice job.

Andy

WOW Joe, you are doing outstanding work and moving at a record pace! You make things look so easy! I know I have been struggling, but seeing your post gives folks like me hope! LOL

Thanks guys.

We all have our strengths and weaknesses. The next step for me is one of my weaknesses.

2/14/23 - I finished the framing of the O gauge bench work. This monstrosity........I mean engineering feat of modern construction ![]() actually has a purpose. I will be constructing a double track curved trestle at some point. I wanted to provide a low base for the bottom support. Looking back I'm sure I could have come up with an easier way to build this instead of angling all of the framing.

actually has a purpose. I will be constructing a double track curved trestle at some point. I wanted to provide a low base for the bottom support. Looking back I'm sure I could have come up with an easier way to build this instead of angling all of the framing. ![]() However, it will serve the purpose and eventually be covered up.

However, it will serve the purpose and eventually be covered up.

I also installed the the pipe hangers for the wiring. Well, I installed most of them until I ran out. ![]() Not sure how I miss counted by 13. Oh well, I'm sure I will be back to Home Depot someday.

Not sure how I miss counted by 13. Oh well, I'm sure I will be back to Home Depot someday.

Attachments

The benchwork looks great, Joe! That will make for a nice curved trestle. I can easily miscount! I needed more hangers, and totally forgot to get any last trip to the store.

Joe, I also posted this in your thread about decking and the next step for the layout. Alex Muller had a terrific layout called the Hidden Pass Junction RR. He has some interesting benchwork and hopefully some possible solutions for you too. Here is the link: https://ogrforum.ogaugerr.com/...-andamp-video?page=1

Andy

Thanks Andy.

Very impressive, Joe.

Tom

Looks great Joe. I would recommend a tie wrap (which you may already be planning), every few feet to hold the wires tight above the standard gauge line. Wouldn't want a loco to grab a low hanging wire and start pulling.

And if I remembered everything I needed on each HD/ Lowes trip, I would be amazed.

Bob

Nice curve base Joe, I am it will work just as you envisioned it too! If not I am sure you will figure it out and come up with something spectacular!

Let's hope Mike. ![]() Thanks!

Thanks!

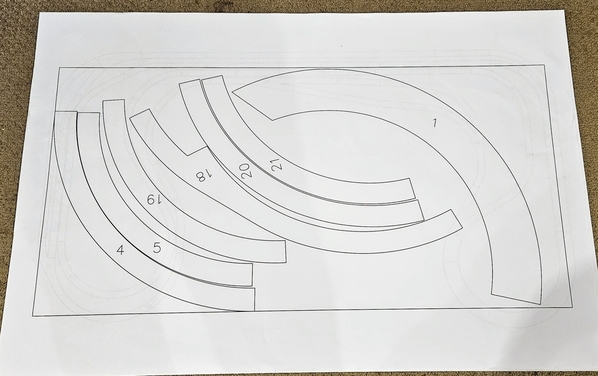

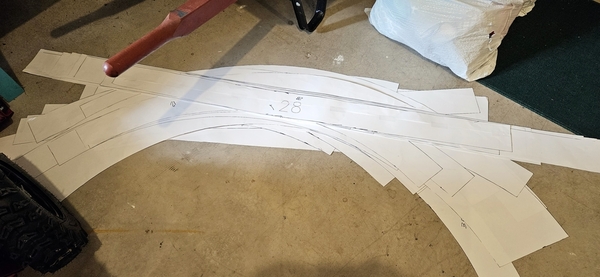

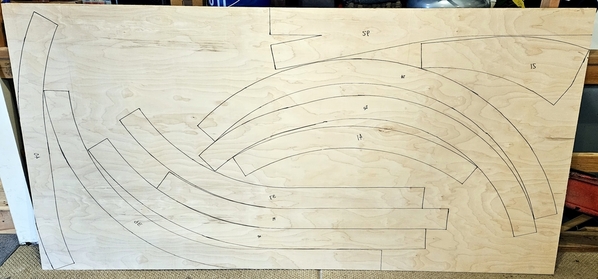

3/24/23 - The roadbed for the O gauge track has been cut out. I posted another thread on the Forum asking for other member's opinions on how to make the roadbed since this type of construction is new to me. I got a lot of good information. I ultimately decided to cut the roadbed out of 1/2" birch plywood, following the curves and straights of the layout of the track.

I drew the layout of the roadbed on CAD. I then broke it up into sections where I thought it would lay out the most efficiently on the plywood sheets.

Then on the computer I took those sections and fit them together on 4'x8' sheets of plywood, arranging them for the best fit and minimizing plywood waste. It worked out that I need four sheets of plywood. Here is a drawing one of the layouts.

Next, I printed out full size drawings of the plywood layouts. I then cut out each paper piece of roadbed. These paper patterns were laid on top of the plywood sheets and traced with a marker.

Then it was time to fire up the jig saw. It did take a while to get all the pieces cut out. ![]() The roadbed sections were taken downstairs and laid on top of the L-girder benchwork. It took some maneuvering to get everything correctly in place. I still have to do some minor trimming and also add some additional joists where needed.

The roadbed sections were taken downstairs and laid on top of the L-girder benchwork. It took some maneuvering to get everything correctly in place. I still have to do some minor trimming and also add some additional joists where needed.

Next will be the splices for the roadbed sections and the installation of the riser supports.

Attachments

@NJCJOE this is some incredible work! Thanks for sharing and keep up the great work!

Looks good, Joe - what was the thickness of the birch plywood you used for the roadbed ?

@NJCJOE posted:3/24/23 - The roadbed for the O gauge track has been cut out. I posted another thread on the Forum asking for other member's opinions on how to make the roadbed since this type of construction is new to me. I got a lot of good information. I ultimately decided to cut the roadbed out of birch plywood, following the curves and straights of the layout of the track.

I drew the layout of the roadbed on CAD. I then broke it up into sections where I thought it would lay out the most efficiently on the plywood sheets.

Then on the computer I took those sections and fit them together on 4'x8' sheets of plywood, arranging them for the best fit and minimizing plywood waste. It worked out that I need four sheets of plywood. Here is a drawing one of the layouts.

Next, I printed out full size drawings of the plywood layouts. I then cut out each paper piece of roadbed. These paper patterns were laid on top of the plywood sheets and traced with a marker.

Then it was time to fire up the jig saw. It did take a while to get all the pieces cut out.

The roadbed sections were taken downstairs and laid on top of the L-girder benchwork. It took some maneuvering to get everything correctly in place. I still have to do some minor trimming and also add some additional joists where needed.

Next will be the splices for the roadbed sections and the installation of the riser supports.

Wow Joe you’re a one man engineering firm. Very impressive.

Jay

WOW Joe not only Amazing and a ton of work! But your the only person I know who has a printer that can print out a 4'X 8" Print!![]()

Things are really looking outstanding!

very professional

Joe, well thought out design and the craftsmanship is spot on!

Gene

@mike g. posted:WOW Joe not only Amazing and a ton of work! But your the only person I know who has a printer that can print out a 4'X 8" Print!

Things are really looking outstanding!

Actually, I had to make 2'x8' prints and splice them together. ![]() Our work plotter only goes up to 36" wide.

Our work plotter only goes up to 36" wide.

@NJCJOE posted:Actually, I had to make 2'x8' prints and splice them together.

Our work plotter only goes up to 36" wide.

fringe benefits from work! Very cool!

I guess I if needed I could always go to the local printing shop and have them do it! Thanks for the information.

Joe, using the computer really made for a great use of plywood! By the time I was ready to print my layout plan, I no longer had use of the plotter at work since I was retired. Printing over 100 8-1/2x11 sheets and taping them together was a pain and a cause of slight misalignment. The roadbed looks like it will work out great!

@mike g. posted:fringe benefits from work! Very cool!

I guess I if needed I could always go to the local printing shop and have them do it! Thanks for the information.

@NJCJOE- great work on the roadbed. A little time spent in CAD saves a lot of time in the shop (and a lot of wasted plywood). I have a 36" wide format printer in my office too. It's only B&W though so I can't print my backdrops on it.

Bob

@NJCJOE posted:3/24/23 - The roadbed for the O gauge track has been cut out. I posted another thread on the Forum asking for other member's opinions on how to make the roadbed since this type of construction is new to me. I got a lot of good information. I ultimately decided to cut the roadbed out of birch plywood, following the curves and straights of the layout of the track.

I drew the layout of the roadbed on CAD. I then broke it up into sections where I thought it would lay out the most efficiently on the plywood sheets.

Then on the computer I took those sections and fit them together on 4'x8' sheets of plywood, arranging them for the best fit and minimizing plywood waste. It worked out that I need four sheets of plywood. Here is a drawing one of the layouts.

Next, I printed out full size drawings of the plywood layouts. I then cut out each paper piece of roadbed. These paper patterns were laid on top of the plywood sheets and traced with a marker.

Then it was time to fire up the jig saw. It did take a while to get all the pieces cut out.

The roadbed sections were taken downstairs and laid on top of the L-girder benchwork. It took some maneuvering to get everything correctly in place. I still have to do some minor trimming and also add some additional joists where needed.

Next will be the splices for the roadbed sections and the installation of the riser supports.

Impressive!!!!!

Peter

@NJCJOE posted:3/24/23 - The roadbed for the O gauge track has been cut out. I posted another thread on the Forum asking for other member's opinions on how to make the roadbed since this type of construction is new to me. I got a lot of good information. I ultimately decided to cut the roadbed out of birch plywood, following the curves and straights of the layout of the track.

I drew the layout of the roadbed on CAD. I then broke it up into sections where I thought it would lay out the most efficiently on the plywood sheets.

Then on the computer I took those sections and fit them together on 4'x8' sheets of plywood, arranging them for the best fit and minimizing plywood waste. It worked out that I need four sheets of plywood. Here is a drawing one of the layouts.

Next, I printed out full size drawings of the plywood layouts. I then cut out each paper piece of roadbed. These paper patterns were laid on top of the plywood sheets and traced with a marker.

Then it was time to fire up the jig saw. It did take a while to get all the pieces cut out.

The roadbed sections were taken downstairs and laid on top of the L-girder benchwork. It took some maneuvering to get everything correctly in place. I still have to do some minor trimming and also add some additional joists where needed.

Next will be the splices for the roadbed sections and the installation of the riser supports.

Now THAT is how you build model railroad benchwork!

You should submit this as an article in OGR. You've already written most of the text and have great pictures. It would be a service to your fellow modelers, and you'd make a few hundred bucks.

Excellent process and execution Joe. Well done and impressive.

Andy

05/07/23 - The O gauge roadbed installation is complete. It was more work than I had anticipated. A lot of checking and re-checking levels to get everything right. I have a few small grades going from one end of the layout to the other. I was able to keep the maximum grade at around 1-3/4%, most is closer to 1%. I was amazed at how many roadbed splices and risers I need to cut. Here are some of them.

Once all the sub-roadbed was in place, I covered it with the foam roadbed a lot of the modelers get from the gentlemen on Ebay. The stuff is great. So easy to work with. I did find cutting the section down the middle for the curves made it easier to lay down. This was attached to the plywood sub-roadbed with white glue.

I'm sure a lot of you have been following corsair29's layout build and deconstruction thread here on the Forum.

https://ogrforum.ogaugerr.com/...tructon-update4-7-13

Steve is a friend of mine and I had always admired his double track curved trestle he had on his layout. I spent a lot of time over the years studying the trestle and taking pictures of it. When it came time to design my layout, I had decided to incorporate a similar type trestle. So, at the end of one of my islands I left a depressed area for this future structure.

Well, Steve has started dismantling his layout for a future move. ![]() He graciously offered the trestle to me for use on my layout. After a lot of measuring and tweaking of my layout design, I was finally able to get Steve's trestle to fit my benchwork. I am so excited to have this as part of my layout. Steve and his brother did an amazing job building this structure and I'm honored that it can continue to have trains running across it. Thanks my friend.

He graciously offered the trestle to me for use on my layout. After a lot of measuring and tweaking of my layout design, I was finally able to get Steve's trestle to fit my benchwork. I am so excited to have this as part of my layout. Steve and his brother did an amazing job building this structure and I'm honored that it can continue to have trains running across it. Thanks my friend.

Next up is track laying. ![]()

Attachments

My hat's off to you. Great, great work.

Steven J. Serenska

Joe, it was worth the tweaking. That will make a stunning feature on your layout, as it did on Steve's. well done.

Andy

Attachments

Wow! Progress is fantastic and the curved trestle is amazing. Thanks for sharing

I’m so glad it fit your layout.

Cant wait see trains cross it again!

@NJCJOE posted:I was amazed at how many roadbed splices and risers I need to cut.

Next up is track laying.

Isn't it amazing how the time to do a planned project expands exponentially!

Well done, Joe.......really exceptional. The fact that you could fit in Steve's trestle is really great.... Steve's layout will live on in yours! Very, very, cool!

Good to see you at York.

Peter

Joe, your roadbed looks great! Steve’s trestle really fit in well with your tweaking. What a great job he and his brother did with it!

Everything is looking great Joe! That trestle worked out very well!

Not much left to say.....glad that trestle didn't wind up in the dumpster.

Looks great Joe..

Bob

It's very cool that you found a home for the trestle, nice new feature! ![]()

Amazing work, amazing track plan, awesome trestle…. I need to sit back and review your excellent carpentry and attention to design before I say more. It’s a Wow! I’ll chime in later. Happy Railroading Everyone

@NJCJOE Joe your workmanship is awesome!! So happy you were able to save Steve's trestle!

Nice work Joe, I am still amazed with your skills in building this layout and to have a friend like Steve is like icing on the cake! It just reaffirms the generosity of the members here!

Your layout is definitely going to be one of those layouts that everyone is going to want to visit! Keep up the amazing work!

Joe:

Are trains running yet across Steve's trestle?

Walter

@Walter Matuch posted:Joe:

Are trains running yet across Steve's trestle?

Walter

Only in my mind Walter. ![]() Track laying is just about to start.

Track laying is just about to start.

Hi Joe,

Everything is looking great !

Alex

Joe,

From one fabulous layout to the next. What a lucky trestle. Looks great and you made it fit like a glove.

Dave

Looks amazing Joe! I can see it is really going to be a focal point of your layout!

5/20/23 - Track laying has begun. ![]() This is my first time working with Gargraves flex track. It is a bit of a learning curve. However, over the years I have picked up some tips here on the Forum and on the internet that have come in handy. Maybe I should do and article for OGR magazine.

This is my first time working with Gargraves flex track. It is a bit of a learning curve. However, over the years I have picked up some tips here on the Forum and on the internet that have come in handy. Maybe I should do and article for OGR magazine. ![]()

Still a ways to go but progress has been made.

Attachments

Looks great Joe!

Dave

When's train night????

Joe, it looks like you learned well! 👍🏻 I never got the knack of making smooth curves with GarGraves flex track!

@NJCJOE posted:5/20/23 - Track laying has begun.

This is my first time working with Gargraves flex track. It is a bit of a learning curve. However, over the years I have picked up some tips here on the Forum and on the internet that have come in handy. Maybe I should do and article for OGR magazine.

Still a ways to go but progress has been made.

Railroad poetry Joe.

@corsair29 posted:When's train night????

Sometime in the next couple of weeks. ![]()

I’m having major train withdrawal!

@Tranquil Hollow RR posted:Railroad poetry Joe.

Why can’t I ever come up with such catchy comments? 😄

Mark, your insights and accomplishments are more than catchy.

@Tranquil Hollow RR posted:Mark, your insights and accomplishments are more than catchy.

Thank you 🤔

Looking great Joe! Good start!