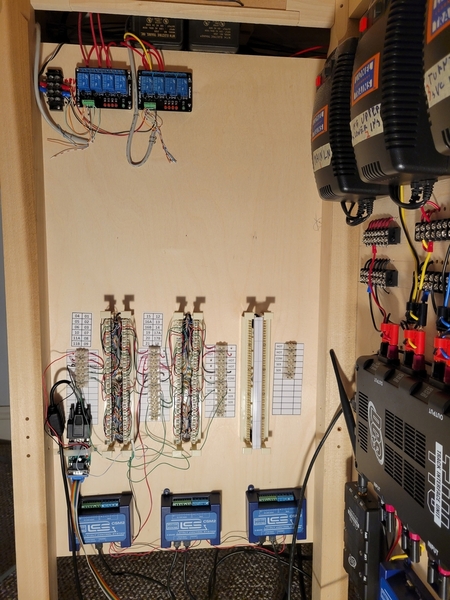

I have been working on my new layout for several weeks - doing benchwork, running bus wires, working on track layout, etc. I decided to tackle the power center before actually laying track and went with, what I think, is a creative way to mount and operate the ZW-L. The "reveal-a-shelf" brackets are used in kitchens, generally for mixers (up to 60 pounds) to be stored out of sight in a cupboard. I figured it would work for my transformer and Legacy command base. When ready to use, simply pull the shelf up and out until it locks. When finished, pull the levers and lower it out of the way.

The sides of the cabinet house the Power Bricks for the outer 3 tracks, which will be Legacy only. The ZW-L will handle the inner 2 loops and allow for the option of command or conventional control, and control 2 accessory bus lines.

Dennis