i had a lot of free time today, so i decided to repower an early, and broken, durham 0-4-0.

it started innocently enough, i did a little mock up with a bunch of spares.

then i got the motor to fit right, witch was a job in itself, and built the rear truck. then decided to go with some bigger rear wheels. and spent far too long fashioning the pilot from scraps.

with everything together i’d say it looks fairly respectable, although i still need to put together some drive rods, and a headlight, and tweak the pilot a little more.

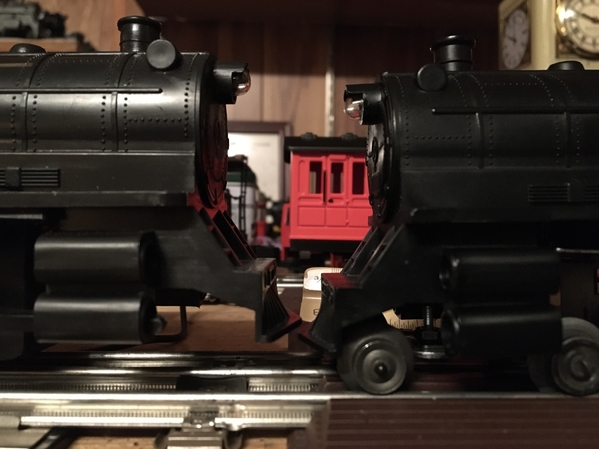

for reference, here’s a stock durham also in my collection. this one is a lot newer, but it looks mostly the same. although the older body i used doesn’t have a cutout for the brake lever like this one.

an interesting note is how much lower the body sits now, i think it looks nicer sitting lower, although i didn’t intend on it.

if your curious about the tender in the first pic, it’s a marx with lionel trucks and an operating coupler i made a while back, i just thought it matched up nicely. i’ll post some more pics as i work on it, and probably some of the internals after i get everything perfected.