I live in a split level and only have half a basement. My wife said the biggest layout I could put down is a 5x9. I’m hoping 060 fastrack will fit the curve on 5 feet. My problem is where do I get a piece of 5x9 3/4 plywood at? Does anybody know where I could find that size? It would be truly helpful as I went to several lumber yards and didn’t have any interest in helping me with one sheet of plywood. I live in NJ and can drive a long way to pick it up. Thanks

Replies sorted oldest to newest

I needed a 5x8 piece for a bed I was building,.. Since its supported I used a biscuit joiner to butt and glue it together. Later I discovered cabinet builders get special larger sheets. So check with a custom cabinet maker,

5 X 9 just a little short for o60...need 6ft min

Do a search on Baltic Birch near you and get two 5x5 foot sheets in 1/2 inch....and make a 5x10 layout. Stay away from the Big Box stores unless you don't have a choice.

You can add a strip to the side in various ways to give you the additional width for 60" or 64" curves.

Go to Menards website in the banner. Roseburg 3/4” x 5’ x 10’ fir plywood sanded one side. This particular plywood is very stable as it is about 10 ply. Although there are other types of plywood which are of a better suited for model train layouts they are not available in 5’ x 10’. The post above has the best suggestion though, two 5’ x 5’ x 1/2” Baltic birch is your best case scenario

Baltic birch plywood is sold in 5'-by-5' sheets in New Jersey. Look online. I used two such sheets to make my 10'-by-5' layout with Atlas O-54 curved track which leaves about two inches between the track and the edges of the plywood.

MELGAR

Merlin,

Best you will probably be able to do on 5x9 is 054. Where are you in NJ? I believe most fully stocked lumber yards can special order a 5x9 sheet. Another choice would be to pick up a ping pong table from a gaming store. That is the standard size. The ping pong table may fold so you might have to add some center support but that wouldn't be too difficult.

John

I must be old school. 3/8" thick plywood is sufficient with a sound deadening 1/2" (homasote) board atop. (There are other sound deadening materials also.) No problem standing on the table. As you get distance away from the New York City area, some Home Depot stores will cut the boards for you. Call around.

@Bruce Brown posted:I must be old school. 3/8" thick plywood is sufficient with a sound deadening 1/2" (homasote) board atop. (There are other sound deadening materials also.) No problem standing on the table. As you get distance away from the New York City area, some Home Depot stores will cut the boards for you. Call around.

No offense...but I would NOT walk on 3/8 plywood. There are many variables involved...but why bother? It's harder to find than 1/2" and costs almost the same.

Also, Baltic Birch has more layers than regular plywood. It's stronger.

I over-engineer everything I build....unlike the windmills in TX. (You get my point....and hoping everyone in TX is OK these days.)

As LionelFlyer suggested, Step back and take an alternate look-see. 5 X 9 is a full size ping pong table size. You can even get a 5 x 9 that folds up and rolls away. Awhile ago I found a lumber yard home center which was selling 5 x 9 tables with a slotted 3/4" plywood frame that went together with out any fasteners. Slick idea for temporary use table.

5' X 10' X 1 1/8" is an available size in the laminate counter top industry. I ordered two sheets. Heavy, but lasted 23 years and stayed perfectly flat.

In South Jersey, Fessenden Hall stocks the counter top material. At least they did, I have not needed any for a while.

I walk on my layout that uses 1/2 plywood but only cause of 4x2 support boards every 18-24 inches. I might add that I can feel some slight plywood movement under me. I doubt I would feel much if it were 3/4" plywood. Especially 7 ply and higher.

For those of us who are in the design phase of their layout construction, you may want read these posts then consider a bench work design that provides comfortable reach so that climbing up onto the platform deck is not necessary.

In the normal progress of life we get older and our joints become less friendly.

@lionelflyer posted:Merlin,

Best you will probably be able to do on 5x9 is 054. Where are you in NJ? I believe most fully stocked lumber yards can special order a 5x9 sheet. Another choice would be to pick up a ping pong table from a gaming store. That is the standard size. The ping pong table may fold so you might have to add some center support but that wouldn't be too difficult.

John

Yup, my first layout was built on a repurposed ping-pong table. A nice 5x9 in two sections. Worked great until The Old Man decided he needed a piece of plywood for a small cabinet he was building and cut a hunk off the corner of the layout, lol.

PD

I'm in the 3/8" or 1/2" with good support camp. IMO, 3/4" is overkill, and it's cumbersome to handle.

I think that making it from multiple sheets is the better option - just make sure it's supported properly.

I'm not big on ordering plywood - I like to examine it before buying - I've seen too many sheets with cracks, voids, delamination, warping, or mold. Unless you have a vehicle that can transport something bigger than a 4x8, it seems like having one sheet delivered would be prohibitively expensive. And it might be a challenge to wrangle a 5x9 or 5x10 sheet through the house and into the train room.

@Merlin posted:I live in a split level and only have half a basement. My wife said the biggest layout I could put down is a 5x9. I’m hoping 060 fastrack will fit the curve on 5 feet. My problem is where do I get a piece of 5x9 3/4 plywood at? Does anybody know where I could find that size? It would be truly helpful as I went to several lumber yards and didn’t have any interest in helping me with one sheet of plywood. I live in NJ and can drive a long way to pick it up. Thanks

Fessenden Hall in Pennsauken NJ stocks 5x5 birch veneer plywood they may also stock 5x9 as well. I’m not sure if they will sell retail. You may need to order what you want from another full service lumber yard not HD or Lowes. I’d give them a call and find out.

060 Fastrack curves will not fit on a 5 foot wide table without an overhang. I tried it.

Also, you may consider using Mianne for your benchwork. I built a 5x10 layout and Tim gave me the measurements for cutting the plywood to fit. I was able to get standard 4x8 birch veneer plywood at the Home Depot and they cut it to fit. It worked out very well.

The Mianne system provides you with everything you need to assemble your benchwork. It’s a real time saver. A 5x9 kit is standard if you need to stay with that size.

Another product, used by exterior sign contractors. MDO board, either one, or two finished sides. Better grades of Plywood, A/C The A grade side is exceptional, C not so much, but you only need one very good surface side.

A/C plywood.

Module base is 3/16" masonite, that worked well with cork roadbed.

MDO (Medium Density Overlay)

Part of the construction is good framing. I used 2" X 4" white fir framing lumber, nothing was longer than 5 ft. Most cases White fir has to be purchased 10ft or longer. (10 ft lumber, cut to (2) table joist).

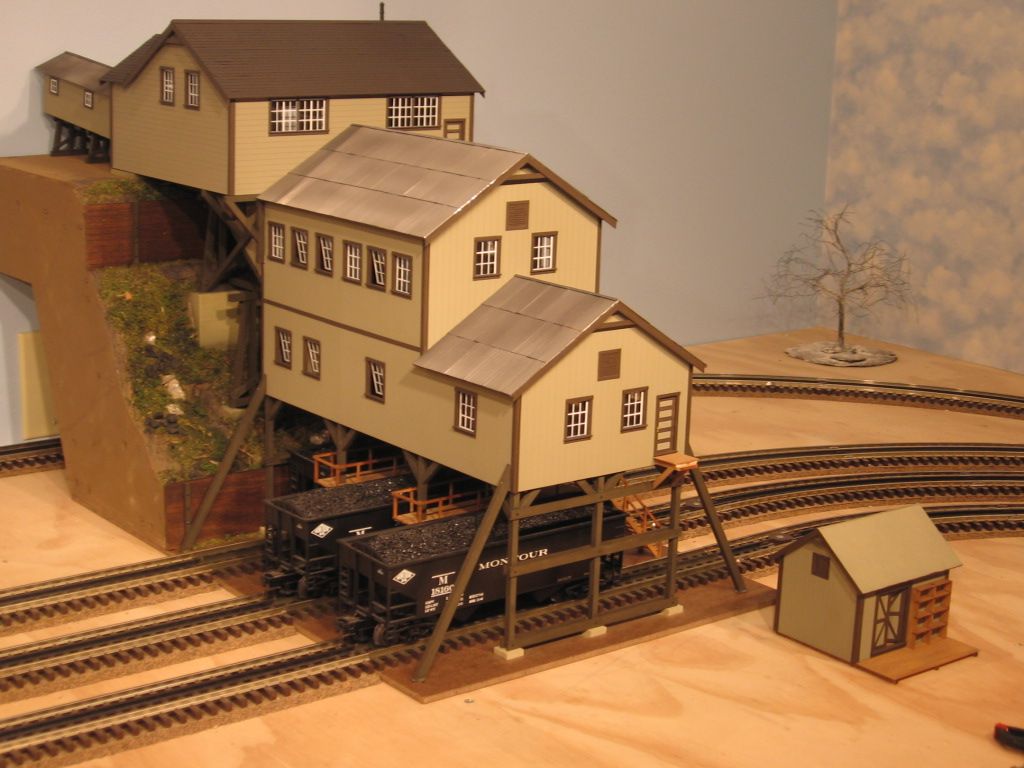

Attachments

@WaynePa posted:Fessenden Hall in Pennsauken NJ stocks 5x5 birch veneer plywood they may also stock 5x9 as well. I’m not sure if they will sell retail. You may need to order what you want from another full service lumber yard not HD or Lowes. I’d give them a call and find out.

060 Fastrack curves will not fit on a 5 foot wide table without an overhang. I tried it.

Also, you may consider using Mianne for your benchwork. I built a 5x10 layout and Tim gave me the measurements for cutting the plywood to fit. I was able to get standard 4x8 birch veneer plywood at the Home Depot and they cut it to fit. It worked out very well.

The Mianne system provides you with everything you need to assemble your benchwork. It’s a real time saver. A 5x9 kit is standard if you need to stay with that size.

Same here exactly. My PW style layout is 5x9 built on a Mianne benchwork kit. Tim gave me the cut #s for fitting pieces of plywood and fastening it all together. Very sturdy and happy with the results.

just checked the price of 3/4 vs 3/8 plywood at Menards. $14 extra per 4x8 sheet. 7 sheets would be a fair sized layout. Less than $100.

@Tom Tee posted:..................... consider a bench work design that provides comfortable reach so that climbing up onto the platform deck is not necessary.

YES! Test what you can handle - how far can you reach and then straight arm your heaviest loco? Don't build bench work that you can't handle your equipment on comfortably!

Access to all the layout is important. Lift out section.

I grew up in a split level in NJ. The lot was 40' so the house was probably about 28 feet across and the basement was half. We had laundry and a lot of crap down there and a 4x8 HO layout and the basement flooded with two inches of water frequently. Knowing what I know now, I would suggest you even look at two smaller turning loop tables connected by a narrow shelf and could run behind the oil tank or furnace or whatever.

My layout is 5' x 9.5'.

1/2 inch plywood is totally sufficient, if you space your support cross members (5 ft "joists") 12 inches apart.

You can put lots of weight on it is and it won't give, provided that you use 2x4 joists (across the 5 ft width). Want it super rigid? Glue the plywood down on the frame and joists using PL3 Construction Adhesive from Lowes or Home Depot. Make sure you lay the plywood down perfectly on the adhesive, because you only get one chance to put it down. You won't be able to shift it once you set it down, unless you do it during the first 10 seconds and use hammer blows.

You can get away with using 2x3 cross joists, instead of 2x4s, if you glue the top down, but your outside rim joists, frame, need to be made of 2x4.

My table is all 2x4s, with 1/2 inch non-glued plywood, with 6 legs made by joining a 2x4 to a 2x3. Each leg has a pair of 1 x 2 diagonal supports, so that the legs don't move sideways. It is extremely strong. I can nail and screw on it, and nothing bounces.

Many folks apparently prefer the use of 1x4s for all framing, so that their table is very light. 1x4s can be very strong if properly used, but nailing in the ends is more difficult because of its thin 3/4 inch thickness. Instead you could use the 2x3s, because they cost the same as 1x4s, and it is extremely easy to use #12 framing nails (sinkers) to nail it all together. And, if you use screws to fasten the table top down, it is extremely easy to line up and sink the screws down into the sides of the lumber.

As for weight of the table, my table weighs 95 pounds, about the same weight as a 12 year old. I put furniture sliders underneath all 6 legs and I can slide it by pushing it with one arm. I don't find this to be difficult, clumsy or stressful.

Hope this helps.

Mannyrock

P.S.- I see that alot of folks like to have A-B or A-C plywood, so that the top of the plywood is A grade, meaning virtually perfect, sanded and with any knot holes filled and blended.

I went with B-C, sanded. The sanded B side is not absolutely perfect. It has a few small imperfections such as occasional rough grain, occasional dings, dents, tiny unfilled knotholes. I use this because I think that when painted with flat paint, the B side looks a little more realistic to me, more like ground.

Mannyrock

I am tickled pink about my choice of Baltic Birch 5' x 5' 1/2" sheets, it worked out great. With 11 plies, it's very rigid and I have high expectations that warping will not be a factor at all. IMO you buy good wood for the benchwork, the difference in price isn't that great when you consider how much money and time you're going to sink into the layout that goes on top!

I spent an extra $150 for the Baltic Birch over the cheap big box store plywood. Considering I have thousands of dollars in Ross switches and track, and almost two cases of Gargraves Flex on top, the $150 was a pittance as far as the overall expense! Don't skimp on the foundation for your layout, you'll forever have to live with the results!

check Craigslist for a used ping pong table. Dont just pass on one that folds up,it might be useful. Hope this helps

Do you guys find that the birch plywood comes relatively flat (compared to the warped junk at the box stores) ?

Don

@dmestan posted:Do you guys find that the birch plywood comes relatively flat (compared to the warped junk at the box stores) ?

Don

Regular birch veneer plywood is much smoother and is generally flatter than pine. Baltic birch is even better, but it's much more expensive and comes in odd sizes.

@gunrunnerjohn posted:I am tickled pink about my choice of Baltic Birch 5' x 5' 1/2" sheets, it worked out great. With 11 plies, it's very rigid and I have high expectations that warping will not be a factor at all. IMO you buy good wood for the benchwork, the difference in price isn't that great when you consider how much money and time you're going to sink into the layout that goes on top!

I spent an extra $150 for the Baltic Birch over the cheap big box store plywood. Considering I have thousands of dollars in Ross switches and track, and almost two cases of Gargraves Flex on top, the $150 was a pittance as far as the overall expense! Don't skimp on the foundation for your layout, you'll forever have to live with the results!

Absolutely! This is today's winning answer.

@Mannyrock posted:My layout is 5' x 9.5'.

1/2 inch plywood is totally sufficient, if you space your support cross members (5 ft "joists") 12 inches apart.

Mannyrock

What size 1/2" plywood pieces?

John

@Bruce Brown posted:I must be old school. 3/8" thick plywood is sufficient with a sound deadening 1/2" (homasote) board atop. (There are other sound deadening materials also.) No problem standing on the table. As you get distance away from the New York City area, some Home Depot stores will cut the boards for you. Call around.

With all due respect, I really can't agree with you. I had 3/8" plywood on Panhandle 1. It was not sufficient, requiring either bracing every foot or rebuilding. I wouldn't stand on it either. The very small cost savings from buying 3/8" are overshadowed by the additional work needed to make it useful.

George

@dmestan posted:Do you guys find that the birch plywood comes relatively flat (compared to the warped junk at the box stores) ?

There's not even a comparison between the two! The Baltic Birch is perfectly flat, it's actually the choice for many cabinet makers. I did get to pick my sheets from a new stack, but there was no picking involved. Every sheet I pulled off the four foot high stack of Baltic Birch was perfectly flat. The only reject was one that has a significant ding in the side, probably from running into a forklift if I had to guess.

@Mallard4468 posted:Regular birch veneer plywood is much smoother and is generally flatter than pine. Baltic birch is even better, but it's much more expensive and comes in odd sizes.

Actually, before the absurd run-up in lumber prices, Baltic Birch wasn't all that expensive. I bought my 5 x 5 1/2" sheets for around $24/ea at Russel Plywood in Reading, PA. At the time, a 4 x 8 1/2" sheet of the cheap junk was around $28 at the local big box store, and the difference in quality was mind bending!

The "odd size" of Baltic Birch was actually a plus, given that my base was Mianne benchwork. 4 x 8 sheets don't work that well on Mianne since they're not "quite" wide enough to span the wide gaps. Turns out that the benchwork is measured from center to center on the I-beams, so in order to get to the edge, it's cut-n-paste.

My total bill, including taxes was $312 for twelve sheets of the 5 x 5 1/2" Baltic Birch. If I had bought the cheap warped stuff at HD, my bill would have been $267 with taxes for nine sheets of the crap at HD. For less than $50 extra, I have a base that I'm pretty sure will never warp and was a pleasure to work with during construction!

That being the case, I have no idea where plywood prices are nowadays, I know that it's a whole lot more expensive all around. However, all wood is a whole lot more expensive, so the differential between the good wood and the lousy wood still probably isn't that significant.

@G3750 posted:With all due respect, I really can't agree with you. I had 3/8" plywood on Panhandle 1. It was not sufficient, requiring either bracing every foot or rebuilding. I wouldn't stand on it either. The very small cost savings from buying 3/8" are overshadowed by the additional work needed to make it useful.

The nice thing about the Baltic Birch is it's harder wood than normal pine plywood, so the 1/2" stuff is really as stiff (and I'll bet as strong) as a 3/4" plywood.

I called a couple lumber stores and got in touch with one and he thinks Baltic birch would be best. He said he will call me later because he has to call a cabinet maker that might have that size in stock. Crossing my fingers. “ Bummer O60 won’t fit on the 5 feet board. I spent over 100 bucks buying the track”

To clarify what us old timers used to do.... 3/8" plywood, even from Home Depot, was sufficiently sturdy when you add a 1/2" layer of Homasote on top that is attached to the wood with drywall screws. Warping is not an issue.

Now I’m thinking about it. Would 5 1/2 wide be able to make the curve on O60? Like Gunrunnerjohn said I can get 2 sheets of 5x51/2 of birchwood and cut 6 inches off each sheet to get me to 9 ft. The only question I have would be if O60 would make the curve at 5 1/2 ft wide? Also wanted to mention that my base for the layout will be a old 8 feet air hockey table. It was built very solid.

@Merlin posted:I called a couple lumber stores and got in touch with one and he thinks Baltic birch would be best. He said he will call me later because he has to call a cabinet maker that might have that size in stock. Crossing my fingers. “ Bummer O60 won’t fit on the 5 feet board. I spent over 100 bucks buying the track”

Too narrow? Just join two pieces. ![]() Glue the tabs on with Tightbond III, toss in a screw to align, then clamp them securely for a few hours. Once you slide it together, it's as strong as the wood, and the edges are perfectly aligned. It's best to do this with the factory edge of the wood to get a clean seam. Credit Tom Tee with this piece of joinery.

Glue the tabs on with Tightbond III, toss in a screw to align, then clamp them securely for a few hours. Once you slide it together, it's as strong as the wood, and the edges are perfectly aligned. It's best to do this with the factory edge of the wood to get a clean seam. Credit Tom Tee with this piece of joinery. ![]()

Attachments

That’s awesome. Clamping the wood together like that.

I had never seen it done like that before, but the fingers really suck it right up to where it's a perfect match. Pretty slick... ![]()

Tom Tee has some very impressive carpentry/cabinet making skills.

Those cuts take some very precise cutting with a saw or require the use of a jig/template and a router.

That's some amazing work....but it takes time/skill. End product is great, though, and totally worth it.

Actually, that particular joint is very "low tech". We just cut some blocks on the table saw and glued and clamped them alternating on the two pieces. You'll notice that there is space between each finger, so alignment is really non-critical. The critical part is having the alternating blocks SECURELY attached to each of the two pieces of plywood and having two very straight edges, hence the factory edge comment. After that, you just slide them together as shown and fasten them down.

Oh, and Tom does have some amazing carpentry skills, it was a non-stop education to see him in action. ![]() All the little tricks that you wouldn't think of, and the knowledge of just the right materials to do the job are things that only experience teaches. I got a small shortcut to some of the techniques watching them get done.

All the little tricks that you wouldn't think of, and the knowledge of just the right materials to do the job are things that only experience teaches. I got a small shortcut to some of the techniques watching them get done. ![]()

I must have done something wrong when I built my last layout. It was built using 1/4 luan and 1x2s spaced every 12" topped with Homasote with everything glues and screwed using Titebond and drywall screws. With support around the edges and a couple girders running down the center it could more than support my weight while I walked/worked on it and it had a 60" width . I did it this way to make it easier to disassemble and transport it when it came time to move and it worked out great. I was able to build and move a 5 1/2 x 10 1/2 foot 3 level layout by myself.

You can see some of the frame construction from these pics take during its disassembly a couple years ago. The main base was traditional 2x4 and 1/2 OSB but I realized if the rest were built like that it would get real heavy, real tall, REAL QUICK! So I came up with this construction technique and for some reason it worked out well for me, your results may vary!

Jerry

Attachments

No offense....but 1/4" luan is one of the worst recommendations you can make for a table top....even if it worked out in your particular instance.

FWIW: note how the above and the 3/8" plywood previously mentioned were combined with Homasote. 1/2" Baltic Birch needs no additional subsurface or substrate.

Everyone has their own opinion and what works for one may not for another. For me my vintage prewar table is 7 x 10. The frame is 2x4 construction on 2 foot centers. The top is sanded 1/2” plywood, maybe 5 or 7 ply. My legs are double 2x4s braced and on rollers. I can easily roll this out to gain access to the back side and to my display shelves. I’m not having any dance party’s on the table but have been on it without any issues. Its plenty solid.

Attachments

@Merlin posted:I live in a split level and only have half a basement. My wife said the biggest layout I could put down is a 5x9. I’m hoping 060 fastrack will fit the curve on 5 feet. My problem is where do I get a piece of 5x9 3/4 plywood at? Does anybody know where I could find that size? It would be truly helpful as I went to several lumber yards and didn’t have any interest in helping me with one sheet of plywood. I live in NJ and can drive a long way to pick it up. Thanks

This may be a long shot or not , but check out your local neighborhood for sale posts . an old pingpong table is the size you are looking for . I actually have one , 5x9x 3/4 heavy as **** but plenty sturdy that I have used as a platform . Pingpong may be a thing of the past now but this post may steer you in the right direction . Good luck .

If you are building a lightweight layout (i.e. modules) 1/4 Luan can work as long as there are sufficient joists. My 2 ft x 4 ft modules use 1x2 joists for 24" spans on 16" centers. . On larger modules I may use 1x3 joists. The module surface remains flat and supports the trains on top, but won't support my weight. For larger tables, I go to 15/32 ply for 4 ft x 4 ft tables with no joists - just a frame made with 2x4s under the edges. That size of table is pretty much at my weight limit for moving at the end of a show. I regularly walk on these 4x4 tables during setup. I have built 3 ft x 6 ft modules from 1-1/2" foam board with the edges framed with 1x3s ... and these are still in use after 25 years. Bottom line is you can build strong and rigid tables out of light weight (quality) materials and good technique.

A key factor is material quality. What normally passes as softwood plywood in the big box stores does not normally qualify. Baltic Birch and domestic Birch hardwood ply is a good alternative. I haven't see any Luan in recent years that matches what I bought years ago, but I found that two layers of 5mm underlayment ply (currently available) glued together makes a rigid 2 ft x 4 ft table surface for modules.

The O.P. was looking for a piece of 5x9 ply. I cringe when I think of the handling problems - it would take 2 people and a truck to get it home in one piece, let alone getting it into a basement. Far better to make three 5x3 tables. (or six 32" x 36" tables that would barely fit O-60 track).

@Berkshire President posted:No offense....but 1/4" luan is one of the worst recommendations you can make for a table top....even if it worked out in your particular instance.

FWIW: note how the above and the 3/8" plywood previously mentioned were combined with Homasote. 1/2" Baltic Birch needs no additional subsurface or substrate.

Over 20 years now, never had an issue on all the portable modules.

The poor OP was probably hoping for a quick answer, and we've given him a graduate-level course in sheet goods. His brain has probably exploded, and now he's decided to go with sheets of insulating foam...

@Berkshire President posted:No offense....but 1/4" luan is one of the worst recommendations you can make for a table top....even if it worked out in your particular instance.

@SIRT posted:Over 20 years now, never had an issue on all the portable modules.

Mine held well for almost 20 years, walked on it extensively during the construction at my mother in laws house after which I dismantled it and took it over my dads where it again went thru several of us walking on it setting it back up where it remained for a couple years until it was taken down again and transported to where I live now and went thru the entire process for a third time along with various reasons for walking on it such as maintenance or to redo a scene. Never once did it groan, creak or crack under any load, warp or twist or begin to come apart despite my early fears it might, in fact after a while I treated it no different than any other layout I have built using more robust construction you could park a car on! I've been watching a good number of maker YouTube videos and all the truly good ones don't shy away from innovation because the "conventional wisdom" tells them otherwise. A construction technique doesn't work "just for you", if it works it works and can be duplicated by anyone, I didn't do anything more than come up with a rock solid light weight construction technique and put it out there for others to try if they want, I didn't just "get lucky".

Jerry

When I built my around-the-room layout I used galvanized studs on 16" centers for the framing topped with 2" rigid foam panels. The only wood used was for the fascia. It will never warp and you could land a helicopter on it.![]()

![]() BTW, the metal studs already comes with cutouts for wiring.

BTW, the metal studs already comes with cutouts for wiring.![]()

Metal framing is interesting, with a lot of different tools, and screws. Metal can be different gauges/thickness. Mechanical contractors, electrical, plumbing, etc. use a stud punch, which speeds additional holes. There are also, an assortment of plastic bushing, for the holes, to eliminate the effects, of sharp metal edges, on non-metallic sheath wire, or Pecks Plumbing.

Vise-grip, C-clamps are used to position metal boxes, to metal studs, before screws are applied. You can do metal studs with a drill/driver. A good driver, and the right screws, work best.

Driver kit pictured.

Have fun, IMO, Mike CT. Decent pair of gloves, and a box of band-aids, need to be added to your tool box. Cutting metal studs is another discussion.

What am I missing here? 2 4x8 sheets of plywood and a skilsaw? However, before I did anything I’d have a look at Linn Wescotts model railroad bench work book.

@johnstrains posted:Same here exactly. My PW style layout is 5x9 built on a Mianne benchwork kit. Tim gave me the cut #s for fitting pieces of plywood and fastening it all together. Very sturdy and happy with the results.

I added locking leveling casters to the Mianne legs so I could easily move the layout away from the wall for access. I was impressed with the transformer cart as well. I was able to attach a power strip using wire ties to the back of the lower support beam to connect my ZW-L and CAB 1-L system to the power outlet.

In order to be able to move the cart away from the layout if necessary, the power connections from the transformer to the track were made using “jones” plugs.

Casters are a good idea if possible, but my layout ain't moving no how, no way at this point! ![]()

Steve,

I'm with you on this one! Cut two sheets to fit, screw the sheets down, let the lumber dry out for 4 weeks, then fill in the seams with a flexible but fast drying caulk. Then paint. If you can still see the seam, then put some landscaping dirt or grass or whatever on top to cover it.

It took me two hours to buy the lumber for my table, four hours to pre-cut all of the pieces, and then four hours to assemble it. Done in 10 hours.

The table was constructed in two halves, and then the halves were bolted together underneath with 3/8 inch bolts. All legs and diagonal supports were attached with self-driving 3.5 inch number 10 screws.

The legs can be removed in 30 minutes, the table unbolted and returned to halves in 30 minutes, and then the two convenient halves easily moved (about 43 pounds each) IF anybody ever wants to move it to a different house.

(Geez)

Mannyrock

I have extensive cabinet making experience and fully understand what 1/4" luan is designed for. If you wish to use it with a substrate/Homasote on a layout, it's a Free Country.

I'll stick to my 1/2" Baltic Birch and 1x4 Construction method.