I've been filtering through the forum looking for an answer. I've been using a circuit protection power strip as extra insurance to protect my layout. I run Legacy & DCS powered by an MTH Z4000. The layout is 14’ x 25’ with 2 basic loops, some over/under track into a tunnel with sidings & a reverse loop/yard area. I ran wire from earth ground along every trouble spot years ago. I have 1 Legacy & 1 TMCC engine that both stop running in the same exact area. The earth ground solution has not solved the problem. Could plugging the Legacy power cord directly into the outlet help, as suggested elsewhere?

Replies sorted oldest to newest

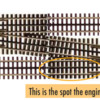

If you are connecting the ground wire directly to the Base with pin #5, then it won't matter if you are plugged into surge protector strips. If your extra ground wire is connected to the house wiring ground after the surge protector, then the surge protector could be attenuating your signal. The best place to connect the ground "antenna" is pin #5 of the DB9 socket on the Legacy Base. You can buy the appropriate gender plug on Digikey, Mouser, or ebay. Maybe Radio Shack which seems to still be around mostly on line.

It wont hurt to try. The only difference would be the strip's light/ led . It shouldn't really matter, but Ive seen far sillier things happen with electronics. If there is no light on the strip all your doing is lowering potential resistance points, Id look elsewhere.

Unfortunately nearly everything (not just trains) with electronics has someplace on earth where it wont behave as designed. Changing outlets or even the direction a unit faced at a certain time of day has been a cure for things I've worked on .... good luck hunting ![]()

There's always the TMCC Buffer if all else fails. ![]()

Yes John, I know. I just missed out on the run, you refunded my deposit, so I have replied I'm interested in the kit when available. Am I on your list?

Thanks,

Joe

gunrunnerjohn posted:There's always the TMCC Buffer if all else fails.

Except they are all "sold out". ![]()

You didn't read far enough Marty, I'm doing another smaller run for the folks that missed out. ![]()

I hope the buffer will solve the problem for those 2 engines, one is my NEW Polar Express. Darn!!!

I'll at least try to take the power strip out of the equation as a test and move forward from there.

ironman1 posted:Could plugging the Legacy power cord directly into the outlet help, as suggested elsewhere?

You could always try it and see if it works.

Removing the power strip from the equation & plugging Legacy directly into the outlet helped in one of 3 locations completely. I can circulate the engines on one complete loop only without them stopping. So what does that mean?

It means that you were not getting enough signal from the earth ground side of the signal. By plugging it in directly to a wall outlet, you got better signal distribution through your home ground wiring. Chances are your power strip is not helping the ground side of the signal. If the signal isn't getting to the house ground properly, all the "ground planes" won't help much.

I use a power strip on my layout with no issues. The layout is 14x14. Two Z4000’s, DCS and Legacy are on the strip.

As everyone has said the key is good ground.

Danr posted:I use a power strip on my layout with no issues. The layout is 14x14. Two Z4000’s, DCS and Legacy are on the strip.

As everyone has said the key is good ground.

It really depends on the power strip. Some of the surge protection in some power strips prevents a good path for the ground portion of the TMCC / Legacy signal to get to the house earth ground.

The previous owner of my house finished the basement, over 35 years ago, which is where my layout is. He considered himself quite the handy man & probably did the electrical wiring.

Carpentry & plumbing are what I will do. I know nothing & do nothing with electricity except turn on a light switch & plug a device into an outlet. How would I know if I have "good ground"?

IRONMAN1- If you have a volt/ohm-meter, check the voltage from the hot to ground/ hot to neutral, at the receptacle. If you have close to 120V then you should have a good ground. It's possible that even though the receptacle has a ground prong that it is not actually grounded. I would open it up and check to see what you have. Trace it back to the panel and see what is going on in there too. Wouldn't hurt to replace the receptacle with a new one too.

With the power off you can check continuity with an OHM meter as well. Should be close to 0 if the wiring is solid.

If you have another outlet near by that you know has a solid ground then run an extension cord and plug your transformers/ bases into that. If the problem goes away then my guess is the problem lies in the circuit you have the trains plugged into.

Finally- a new dedicated circuit from the panel would be my other recommendation.

Beyond that I can't help- I don't run any of the digital systems, strictly conventional in my little world.

Bob

Attachments

The signal is between the outside rails on the track and the connection to the ground wiring in your house. The ground wiring is being used as an antenna to radiate the signal to the antennas in the tops of your engines. It seems that the connection to your house ground wiring is affected by your use of an outlet strip. In that case, pin #5 of the Legacy Base is the better place to connect your additional "ground" wires that you installed to problem areas on your layout. It may be a better solution than eliminating or in addition to eliminating the outlet strip which only helped one of your problem areas.

A couple of things, first of all, thanks for the suggestions. I bought that exact tester years ago and tested my outlets. I don't recall having any problems, so I moved forward with ground wires running almost everywhere along the layout. What a pain that was & I can honestly say at the time, I wasn't impressed with the results. I think my problem is deeper, I'm willing to bet, the earth ground. If I haven't already mentioned, I am clueless to all things electrical, and in regards to the pin #5, I'm not clear on what the suggestion is.

As far as my layout goes, I've been running within the limitations I experience, but that has kept me from moving forward with any kind of scenic improvements or any other additions. I hope to get things figured out eventually but I have a feeling I will need to seek out an electrician to know for sure I'm on the right track.

I came close to selling my TMCC N&W J since I thought it was the problem, not the layout. Now I believe different.

Based on the thoughts here, would the buffer solve my problems, as John had suggested ?

Pin 5 on the 9 pin connector on both Legacy and TMCC bases is the same half of the signal that is put on the earth ground. So in essence if you tap off pin 5 and run it near the trouble spot it's the same as using the earth ground. If your strip is the issue, using pin 5 bypasses the strip.

Roger Wasson posted:

Outlet tester in the generic sense. Available at any Home Depot or such.

MartyE posted:Roger Wasson posted:Outlet tester in the generic sense. Available at any Home Depot or such.

An outlet tester like this is used on a three prong outlet. Purpose (Correct) noted at the bottom of the tester is to assure the outlet is wired properly, two yellow lights, middle and right, will light. The (5) incorrect wiring problems, are noted on the tester. Most common, since a lot of older home wiring, had no ground wires, would be (top) open ground. Open ground a problem with TMCC signal. Often if a two prong outlet broke, or was no longer use-able, it was replaced with a three prong outlet, round third prong bottom not attached to any wiring. larger left slot is attached to the white wire (neutral), smaller right slot is attached to the Black wire (power).

If the outlet is good, don't forget to check all the outlets on the power strip.

This is a simplified statement I think was hinted to above; I think it is possible an outlet could have a seperate earth ground which could test ok. But it still may not be wired to other grounds which themselves are earth grounded elsewhere.

In any case, I think adding wire(s) to pin#5 is the easy way out here.

How would you add wires to PIN 5? Has anyone done that?

Buy one of these...

cjack posted:Buy one of these...

then which pin is 5?

See the pin out diagram on CJack’s first post in this thread.

So, without sounding too dumb, you just solder to pin 5, leave the rest alone & plug into Legacy?

Or is the ultimate solution the TMCC buffer to avoid all this jerking around?

Alright, sorry, I'm tired of feeling like an idiot.

I'm a graphic artist, not an electrical engineer. Ask me what 4 color process is, CMYK, RGB. What are spot colors, UV varnish, overall gloss aqueous. What's a gate fold? Then I'll be able to understand,

While it may be clear to most of you, it's not to me. Sorry, I need to be spoon fed for something of this nature. I can plug something in, I can solder A to B, follow clear directions, otherwise it's mumbo jumbo.

Thanks for the suggestions.

Joe

ironman1 posted:Or is the ultimate solution the TMCC buffer to avoid all this jerking around?

The TMCC booster could be warranted but connecting the ground wires to pin #5 is advisable in any case.

Just solder a wire to pin#5 and leave the other pins alone. Then connect all your ground wires to that wire and place them in problem areas.

Graphics, that makes about eight of us I know of on here now ![]() My real intro to controls began with interest in typesetters and plate cameras.

My real intro to controls began with interest in typesetters and plate cameras.

Don't feel bad Ironman, you are learning

These folks can talk tech lingo that takes time to learn on top of basics I was away for months so also have no clue what the "Buffer" is unless by chance that is Dale M's boost. It also takes time for these folk to gauge your knowledge, and sometimes they try to answer to best help you long term, vs easy peasy, sometimes search homework is expected too. Ask again if it's not clear after some thought though.

Im guessing your baulking at soldering here. It's pretty easy; good solder and clean metal is 75% of it. A good skill to learn in the hobby as well.

But besides solder there is an alternative though a tad slower and more costly (till you can learn to hack like pro's ![]() ). "Pinout" implies a female plug is, or can be utilized. I.e., crimp a female terminal on wire, insert into pigtail plug's hole#5 and plug the thing onto the board. All crimpers are not created equal. Getting a good one makes the job easy. Note for the future, there are even special tools for removing terminals for each socket type as well, though a fat needle or hat pin can often push the tabs for release/removal without plug damage too, the tools are a breeze.

). "Pinout" implies a female plug is, or can be utilized. I.e., crimp a female terminal on wire, insert into pigtail plug's hole#5 and plug the thing onto the board. All crimpers are not created equal. Getting a good one makes the job easy. Note for the future, there are even special tools for removing terminals for each socket type as well, though a fat needle or hat pin can often push the tabs for release/removal without plug damage too, the tools are a breeze.

This is a male plug end view. The female connector assignments are the mirror image.

Chris

LVHR

Attachments

It's starting to make more sense & it's worth a try.

Thanks to all.

If you are using a TPC, the ground plane antenna gets connected to the COM terminal. I could be wrong here as it has been a few years since we did this at our club and it eliminated any TMCC issues we had in tunnels, etc. It might go to the DAT terminal on the TPC.

You can always put a 18 gauge wire into the computer port of a cab-1 into pin #5, the same as described in a previous post.

I found this item on Amazon (Sysly DB9 Male D-SUB Adapter Plate Connector RS232 Serial to Terminal Board Signal Module), see attached image . It may be over the top for my needs, but if the item will work, it's idiot proof. Insert a wire & fan out my ground plains from there? Any particular gauge wire recommended?

A confirmation that this will work would be appreciated.

In my quest for a better signal, I stumbled upon this layout video at various stages.

https://www.youtube.com/watch?v=XtKCk2U8Rao

Seems this gentleman cut aluminum sheets, mounted at every overpass and grounded each. Looks like he has no signal issues. Would it be just as effective if the sheets were stapled to the underside of the plywood overpasses?

Attachments

Do you have other engines that go thru these trouble spots? What does the 2 engines do in the spots,stop and the headlight flickers? Did you try putting your hand over the engine when entering the bad spot and see if it makes it thru that area?

Just some thoughts,Doug

I have 6 Legacy no issues. 1 Legacy & 1 TMCC that stop in 2 of the exact places. In 2 areas engines will stop & restart. 1 overpass stops dead, won't move, needs to be pushed, literally the worst spot, hard to reach. Used to be just the 1 TMCC engine, just stopped running it. Now with a new Legacy engine exact symptoms.

Very frustrating.

Is it possible there's a power dead spot in them areas? Roller spacing is different on different engines.

Doug

I've been giving that a thought. The 2 worst spots are next to each other, 2 tracks side by side slightly different elevations, separate loops. I really think its a ground plain issue.

You might consider the Dale M buffer amp that gunrunnerjohn is offering. Do you have a large layout. Pictures?

I had hopes it would be my answer & I did consider, tried to place the order, sent my deposit & I was too late. John sent a refund. I have mentioned to him, more than once, that I want to be on the list for the kit. He hasn't confirmed my order yet.

He has undertaken an awesome project. Just be persistent and patient

I just watched it & read most of the ground plane posts on the forum. I eliminated the power strip for now & I'm going to try the pin 5 suggestion as a starting point. I'll try connecting all my ground plane wires to pin 5. I think I'm going to remove all my engines & rolling stock & try running one of my problematic engines across the layout & try to identify all my problem areas.

I've been running the layout so long, avoiding the problem engines and areas that are a problem, it's probably time to find a solution. I was looking for a quick fix but I guess there isn't.

A simple thing to try if you think the outlet might not be grounded properly is to remove the screw holding the face plate on and add a wire with a small ring terminal replace the screw and run the wire to a copper water line that's close by.

Doug

Well I tried a number of things. Focusing on one section only. Cleaned the track more thoroughly last night. The troublesome engine ran perfectly, along with 2 other trains for over an hour.

Tried again this afternoon, stopped every time, same spot, actually it's over an atlas switch. Thought maybe the computer & TV/cable, that are in the rooms above, might have an impact. They weren't on last night. Connected a wire to Pin 5, ran a wire above, then along side the troublesome section, no improvement, gave up.

Thought the overhead shop florescent light affected the signal (had it on last night no issue). Tried connecting another wire to the earth ground outlet and ran a wire above then alongside the track, no improvement. Removed an MTH engine form the track on a siding, a considerable distance away, signal improved, the engine ran fine on that loop.

I read somewhere here, that some engines will affect other engines I've long suspected that was an issue in some cases. I'm in the process of removing every engine on sidings not in use. My plan is to remove every engine, every piece of rolling stock & try to see how my Polar Express will run on every loop & siding.

WHAT A PAIN! To many variables. Makes me want to tear it all up and start from scratch! One section, one loop at a time.

I started this layout, maybe 20 years ago, with early DCS. Couldn't wait to get trains running. DCS had some bugs, tried all the suggestions & got things running well enough to enjoy. Once I introduced TMCC, more problems started to pop up.

I really think every time I solved one problem, I introduced a new one.

If I had the time to start fresh, I wouldn't waste my time trying to de-bug this layout.

When that time comes, I will take my time & test as I go along.

Your problem is it's losing power thru that atlas switch,you can run a hundred ground plane wires and it will not cure it. I don't use atlas so I don't know if there's a way to fix them.

Doug

trnluvr posted:Your problem is it's losing power thru that atlas switch,you can run a hundred ground plane wires and it will not cure it. I don't use atlas so I don't know if there's a way to fix them.

Doug

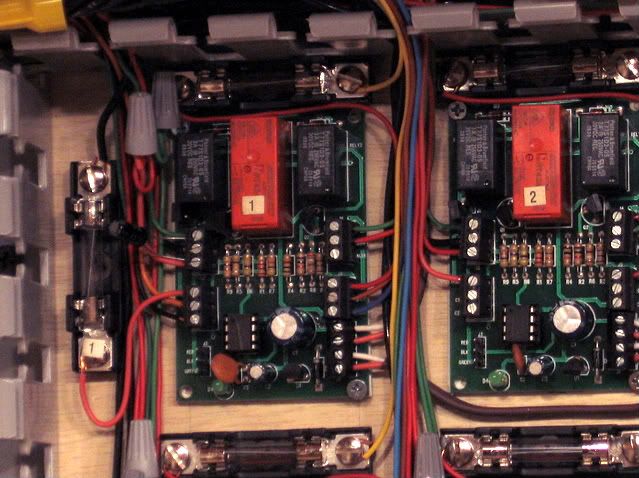

Fix involves wiring with the Atlas 6924 relay board, which logically powers short dead rail sections of switches. There is also dead rail wiring associated with Ross Switches/using DZ 1000 switch motors, and add on 1008 latching relays.

There are at least two pick-up rollers on an engine/locomotive. Unfortunately, with close positioning of switches, and crosses, you can have two holes/non powered sections, that match with an engine/locomotive pick-up rollers.

Atlas 6924 relay board

(2) DZ 1008 relays, mounted under the layout. Black boxes marked (4) and (5)

Well, the switch could certainly be the culprit, in this one location. No switches in the other problem areas, tracks next to each other.

I did a quick check on the relay board, $25.00! No simpler solution. Ross switches also have the same issue?

What does the engine do in them areas ?

Doug

Stops dead mostly, sometimes will start slowly or lurch forward.

Does the headlight go completely out or does it flicker?

Doug

No flickering, completely dead.

That's a power problem too. Are you using the rail joiners for your power drops and how far apart are they? Is there one close to that area? That's the one thing I didn't like about atlas track is the rail joiners,I nothing but problems with it in HO,I ended up soldering all the track back then.

Doug

I like to use multiple power strips for that cascade effect.

Lotta protection here. Please don't do this.

Chris Sheldon

Attachments

FIREONE seems an appropriate user name for that picture! ![]()

![]()

trnluvr posted:A simple thing to try if you think the outlet might not be grounded properly is to remove the screw holding the face plate on and add a wire with a small ring terminal replace the screw and run the wire to a copper water line that's close by.

Doug

As a licensed electrician with over 30 years experience I have one thing to say....

NEVER DO THIS! (sorry trnluvr). Running grounds to any place but the bus bar in your main panel is not only a violation of the national electrical code but could potentially lead to a fire under the right circumstances. I've seen stray voltage as high as 10V with several amps of current on small accessory grounds such as this.

Grounding is much more complex then many people realize, especially with all of the electronics in our homes today. Entire books have been written on the subject (here).

Not only can you introduce stray voltage into your home's electrical system, these small grounds can cause electrolysis in the copper pipe causing it to rot out and leak.

We all love our trains but we all need to be safe with how we use the electricity that runs them.

Bob

RSJB18 posted:Grounding is much more complex then many people realize, especially with all of the electronics in our homes today. Entire books have been written on the subject (here).

They're pretty proud of that book too! ![]() $73.95

$73.95

So, remove the ground wires? Craps, something else to worry about!

I have an older version that I've read several times. Took many classes over the years too.

RSJB18 posted:trnluvr posted:A simple thing to try if you think the outlet might not be grounded properly is to remove the screw holding the face plate on and add a wire with a small ring terminal replace the screw and run the wire to a copper water line that's close by.

Doug

As a licensed electrician with over 30 years experience I have one thing to say....

NEVER DO THIS! (sorry trnluvr). Running grounds to any place but the bus bar in your main panel is not only a violation of the national electrical code but could potentially lead to a fire under the right circumstances. I've seen stray voltage as high as 10V with several amps of current on small accessory grounds such as this.

Grounding is much more complex then many people realize, especially with all of the electronics in our homes today. Entire books have been written on the subject (here).Not only can you introduce stray voltage into your home's electrical system, these small grounds can cause electrolysis in the copper pipe causing it to rot out and leak.

We all love our trains but we all need to be safe with how we use the electricity that runs them.

Bob

Bob, Thank you for setting me straight on this,I was passing it on from posts I have read on here before. Know that I know this I'll never mention it again!

Doug

I’ve seen houses with copper plumbing where the plumbing is connected back to the electric entry panel ground. I think that was a safety in case a live wire was accidentally touched to the copper pipe system. That’s different than what was stated here, but I’m wondering if that’s recommended any longer. I’m thinking that could be an unrecommended additional ground rod in the soil as one caveat.

Anyway, if that is the case and it’s been allowed, ground wires to lay on the layout could just get their ground system signal from a nearby copper pipe.

What does the ground book say about that these days?

I dont think anybody said pull anything yet... except maybe as a process of elimination test on the turnouts.

There are various grades of the LED testers as well. Some can be "fooled" by hacked grounds. The one shown is a good one.

Do you have an ohm meter or similar voltage/continuity meter? You may be able to check for continuity between various wall outlet earth grounds to insure they are wired to the same ground. Plus with those turnouts/motors you should be poking rails for voltage too... but...

I think the video addresses the issue best. But if you've allready mirrored thier solutuons EXCACTY, then the #5 acting as a transmitter antenna negates worrying much about a wall circuit that you have tested in the past. And as noted you might run an insulated wire from the wall plug vs pin 5 and drape it around for testing.

I'm also wondering about your wall construction. Because chicken wire and or gypsum (I think that was it) in plaster could be shielding the in-the-wall signal starting at the wall socket as well. A family member just spent buttload on 6 in-home cell phone relays and a new tv/radio antenna because radio can't pass through the walls and absorbs rather than reflects.

Again, the #5 or the ground equipt with an extension antenna is a cheap diagnostic tool/solution(hopefully).

Or another way to test fast would simply be plug a long grounded extension cord into the same outlet as the command unit and drape that around the room.

Atlas O 3-Rail Nickel Silver track

I still say his problem is power related and not signal issues.

Doug

cjack posted:I’ve seen houses with copper plumbing where the plumbing is connected back to the electric entry panel ground. I think that was a safety in case a live wire was accidentally touched to the copper pipe system. That’s different than what was stated here, but I’m wondering if that’s recommended any longer. I’m thinking that could be an unrecommended additional ground rod in the soil as one caveat.

Anyway, if that is the case and it’s been allowed, ground wires to lay on the layout could just get their ground system signal from a nearby copper pipe.

What does the ground book say about that these days?

I guess our condo didn't get the word that that was prohibited! The one wire is going around the meter and valves, and in the corner shot, the ground wire from the water feed is going up is the power panel ground.

Attachments

I'm sure there is more than one issue and a combination of things. Some engines run fine everywhere, while others don't, but do run fine on certain sections. Right now I'm trying to apply a band aid, not do major surgery. Some of the suggestions have helped so far. I have no doubt the Atlas turnout is one issue, at least for 2 of my Lionel engines. Like I did with the power strip, I'll take it out of the equation, at least temporarily & slip in a straight section.

Process of elimination & I'll give the pin 5 another chance. I may disconnect my ground wires once I've cleared every engine and car off the layout, and run some engines around, one at a time. This may be extreme but I need to remove every variable. It may be awhile though since I'm going away for 2 weeks.

I made up my mind 3 years ago to build a new layout, a walk-in, mostly for better accessibility. Eye level on a bar stool & not always walking around, with no duck unders. All the suggestions here will be most helpful at that time.

One thing I don't believe was mentioned, could wi-fi be part of the problem?

Interesting about the ground to the copper pipe. That was common around here for many years. As in GRJ's pic above, the house we moved from about 5 years ago had the exact same grounding setup (only copper wire) from the electrical panel to the copper water pipe. It also had a ground rod outside driven in the ground below the electric meter that was also tied into the breaker panel. We lived in the old house for about 35 years and it was 22-23 years old when we moved in.

I've never lived where it wasn't that way; pipes to box . There are four total rods around the outside hers and one in the foundation under the water meter.

I assumed it was straight track, and just fully caught the turnout issue. No mention of engine type either, but adding a roller to a tender or swapping for non-stock rollers may be needed.

Ability to run in conventional could be more revealing of a bad roller spacing if you have a throttle, or ability for convetional via command remote, or an old supply with a throttle to swap in.

I don’t think it is prohibited to refer the metal plumbing back to the meter ground. I was wondering though. It is against code to have more than one ground rod unless they are bonded together by a substantial copper around the house. Maybe that’s what a water pipe system is in effect when the water source pipe behaves like a ground rod where it comes into the house.

This comes up all the time with ham radio, especially when we drive additional ground rods at antenna towers. We’re advised to run at least a 1/4 inch tubing from them to the meter ground. It’s about lightening protection although I don’t think anyone actually knows how lightening is going to decide to go. However, the thinking is that most of the damage comes from huge ground currents.

My problematic engines are a TMCC N&W J (4-8-4), & my NEW Scale Polar Express Berkshire (2-8-4). I had a TMCC Y6B that had the same issues, same spots, sold it. I have 2 Legacy Y6B's, as well as 2 Legacy EM1's & a Legacy Sharknose diesel, no issues anywhere.

I'm essentially a loop runner. Just love watching the trains circulate. I'll do switching at some sidings & in a small yard, for fun and a change of pace. My Grandson is 3 1/2 and loves running the trains. He starts them up, increases the speed, blows the whistle & bell, etc. We love watching them together but when the train stops, of course he asks, why? Kinda takes some of the fun out of it. If he sticks with the hobby, I hope he'll be the one ironing out the kinks.

gunrunnerjohn posted:cjack posted:I’ve seen houses with copper plumbing where the plumbing is connected back to the electric entry panel ground. I think that was a safety in case a live wire was accidentally touched to the copper pipe system. That’s different than what was stated here, but I’m wondering if that’s recommended any longer. I’m thinking that could be an unrecommended additional ground rod in the soil as one caveat.

Anyway, if that is the case and it’s been allowed, ground wires to lay on the layout could just get their ground system signal from a nearby copper pipe.

What does the ground book say about that these days?

I guess our condo didn't get the word that that was prohibited! The one wire is going around the meter and valves, and in the corner shot, the ground wire from the water feed is going up is the power panel ground.

To paraphrase the National Electrical Code-

1. A metallic water system that has at least 10 feet of buried metallic pipe MAY be used as one of the required grounding electrodes.

2. If the metallic water system is used as a grounding electrode, the grounding electrode conductor MUST be attached within 5 feet of the pipe's entry into the premises.

3. If the premises contain a metallic water piping system, it MUST be grounded, even if it not used AS the grounding electrode.

4. In the situation where a 3 prong receptacle is used to replace a 2 prong receptacle, the ground pin MAY NOT be connected to the metallic piping system UNLESS the connection is made within 5 feet of the system's entry to the building, per 2 above.

There are a bunch of exceptions and clarifications, but the above 4 points are the jist of it. Not all jurisdictions follow the NEC, so your inspector may be more or less stringent..

All this has changed a bunch over the years, mainly due to situations where sections of rusted or damaged water pipe were replaced with plastic, which broke the ground path.

FWIW, the stuff about ground currents causing corrosion is true, I have personally encountered it, although it took 50 years to show up.

I only know for some reason you shouldn't rely on pipe as the main earth ground for electrical. The electrics earth should be as close the the box as possible.. I dont have copper pipe, it is steel. Ive seen cases for using special pipe joints and sacrificial anoid materials but I was reading blueprints not designing. There is one big ground at the meter middle front of basement. an equal from pipe to box about 40ft away s.w. back corner laundry/electrical. 50ft south another pipe lead to rod. Plus a rod for phone and one for antennas. There is one for gas pipe too I think, n.e. corner(?)

Didn't mean to start a whole thing about grounding. What @PLCProf stated above is all true. The ground clamps that several of you have posted pix of are a requirement in the code. This is your main ground from the panel to earth.

One thing to add- many areas of the country use plastic pipe for water mains. The copper/metal piping in the house still gets bonded (different from grounded) to the electric service but the ground is accomplished with two 8' copper rods driven into the ground outside the house, usually below the meter.

To take it one step further, your home's electric service originates at a step down transformer provided by the local utility. Typically 240V/120V secondary from a higher voltage primary. These transformers are grounded to earth by driven rod as well.

All of these grounds "connect" via the earth.

Bob

So in GRJ’s top photo is that the start of this electrolysis business, or something else? Should we be looking around for this?

Attachments

TedW posted:

It could be. The clamp is aluminum and the pipe is copper. Dis-similar metals can cause electrolysis to begin as well.

GRJ- I would recommend having this clamp changed to a copper/ copper- coated clamp. The water pipe should be cleaned with steel wool or emory cloth to insure a good connection from the clamp to the pipe.

The jumper around the water meter is there so that if the meter ever has to be removed for some reason, the home's piping is still grounded.

Since the ground wire proper is aluminum, and the clamps are labeled AL/CU, I'm going to leave them alone. However, I did take them off, clean the pipe and clamp, and then insure they were as tight as possible. There was no evidence of dissimilar metal corrosion on either joint, so I'm not too worried. By the time it manages to corrode, it should be someone else's problem! ![]()

![]()

FWIW, the wire is continuous from the breaker box through the one clamp and on to the second one. That gives me two points of contact to the pipe unless someone steals the meter. ![]()

I really don't think I have a problem with the grounding as it also was inspected in 2016 and this wasn't squawked in the report.

Sounds good John. As long as the clamps are properly rated then it should be fine. The wire is properly done also.

By the time it manages to corrode, it should be someone else's problem! ![]()

![]()

Good answer! LOL! ![]()

Any update on the new layout build?

Still waiting on the Mianne benchwork, I've been led to believe it takes several months. Tim has my money, I just have to wait until he ships it.

I used Sievers Benchwork. It came right away. Clear pine with predrilled holes for construction and wiring. The only delay I had once was waiting for the ferry to Washington Island to unthaw.

I'm already halfway in bed with Mianne as I have a lot of their stuff, so it's less painful to go that way. ![]() I've seen the Mianne stuff and I like it and so does everyone I know that has used it. I don't know about Sievers Benchwork, it could be great stuff, but I have never seen it, or even heard it mentioned before now.

I've seen the Mianne stuff and I like it and so does everyone I know that has used it. I don't know about Sievers Benchwork, it could be great stuff, but I have never seen it, or even heard it mentioned before now. ![]()

cjack posted:The only delay I had once was waiting for the ferry to Washington Island to unthaw.

Call a crew for the ice breaker, on duty 6:00 a.m. ![]()

gunrunnerjohn posted:Still waiting on the Mianne benchwork, I've been led to believe it takes several months. Tim has my money, I just have to wait until he ships it.

I ordered my on June 7, and it shipped on Aug. 7. Credit card not charged until shipped. Worth the wait.

Steve

Yep, I have no idea if the CC was actually charged, but I figure he's good for it. He swore it would ship before York. ![]()

It's been about a week since any more info has been added to my original inquiry about power strips. A lot of suggestions have been added, and while maybe on the same subject, this thread has gone a bit off track.

The ironic thing about the different approaches I have tried for reliability, at least through one section of track, finding a solution difficult, because of the mixed results. 2 engines stop, almost always, in the same spot at an Atlas turnout. Since replacing this turnout in a permanent section was problematic, I tried less drastic approaches. Finally replaced the turnout with a straight section of track. One engine has run non-stop, forward & reverse, slow & fast dozens of times now. So, what turnout should I replace the Atlas turnout with? I've had no problems with Ross turnouts up to now. Tomorrow I'll test the other engine.

The other 2 problem areas are where parallel tracks at slightly different levels also show signal issues & erratic running.

Switches, by design, have dead spots, where power, to a locomotive, is applied through one, not both contacts, with the third rail. On occasion, roller/contact pick-up, can find two dead spots at one time, and the engine stops. There are power routing solutions to this problem, both Atlas and Ross have work-arounds (previously mentioned in this thread, page 2).

One of the big improvements was Atlas providing (4) roller pick-ups on new models

Why not try Gunrunnerjohn’s (Dale M) signal buffer for the general signal problems?

The switch issues are probably different than your general signal issues.

cjack posted:Why not try Gunrunnerjohn’s (Dale M) signal buffer for the general signal problems?

The switch issues are probably different than your general signal issues.

I believe he is on the list for one of the kit versions.

Yes I am on the list for the buffer kit.

Mike CT posted:Switches, by design, have dead spots, where power, to a locomotive, is applied through one, not both contacts, with the third rail. On occasion, roller/contact pick-up, can find two dead spots at one time, and the engine stops. There are power routing solutions to this problem, both Atlas and Ross have work-arounds (previously mentioned in this thread, page 2).

One of the big improvements was Atlas providing (4) roller pick-ups on new models

As Mike suggests here and others have said earlier, I would try checking this first. It's a pretty common problem that can turn up with any given switch and engine at some time or another. Replacing the switch may (or may not) solve your problem.

I will defer the TMCC signals to the others here more knowledgeable, I have not yet had problems with those (fingers crossed).

I have to admit, the switch issue is a puzzle to me. I understand that with shorter engines the rollers may not be spaced in a way to overcome the dead spot. What I find hard to comprehend is that I only have 2 engines that have the problem at that switch, both Lionel, one Legacy the other TMCC both large engines N&W J (4-8-4), the other PE Berkshire (2-8-4). I even replaced the switch with an extra Atlas switch that matched. Only when I removed the switch & added a straight section did I attain perfect operation.

Is there a preferred way to wire a switch that solves this problem?

As Mike CT suggests above it could be contact with the outer rails as well as the center rail and pickups. It is not surprising that replacing the switch with a straight section of track fixed the problem. That could be another indication of something going on between the switch and those specific engines?

If you can specifically define the problem and describe it here, someone may be able to provide a solution. There are an assortment of folks here that between them have at one time or another experienced most every problem you can imagine. Lots of knowledgeable folks here!

Also, as someone suggested earlier, try holding your hand over the engine when it stops. I have seen this mentioned several times around here and I believe it indicates a poor signal or antenna problem? If something (or nothing) happens, I will again defer to the more knowledgeable here. I have not experienced this problem myself. Although I have a legacy system and a couple of Lionel engines, I am not too well versed on the TMCC/Legacy stuff or their problems.

In this particular area, the engine stops dead, no flickering headlight & the hand over the engine doesn't work. From what I have read here, that would indicate it's not an antenna/signal problem.

I think we may be narrowing it down to a power problem. If it is just these two engines having trouble going over the switch, and you have other engines that travel through the switch with no problems, then it is most likely the two engines that have problems. Sounds like the engines need to be carefully examined, replacing the switch may not solve the problem.

ironman1 posted:What I find hard to comprehend is that I only have 2 engines that have the problem at that switch, both Lionel, one Legacy the other TMCC both large engines N&W J (4-8-4), the other PE Berkshire (2-8-4). I even replaced the switch with an extra Atlas switch that matched.

It's not the size of the locomotive, but rather the placement of the center rail rollers. Some large engines don't have optimum placement of the rollers, nature of the beast.

How about a picture of the bottom of each problem engine and also the measurement between the rollers?

Sounds like a good idea. I'll do that this evening after work.

If I'm not mistaken, I have read here on the forum that early Atlas switches were problematic. I purchased these switches 15+ years ago when I started building my layout.

I attached image above is of the switch in question, it's a #7.5 HIGH SPEED SWITCH-RIGHT.

I haven't even attempted to cross over with the engines experiencing problems.

Attachments

I already sold an engine a year ago that had the same problem, same locations, a Lionel TMCC Y6B. My 2 Legacy Y6B's have no issues in these locations.

I believe it's the high speed switches. I have 2 Ross switches I purchased 2 years ago for this location. I think my intention was was to match the space as close as possible. I think they are the 11 degree turnouts. I don't believe they will drop right in without a little fuss.

Do you have the same problem with these 2 engines in the same location on the other (top) switch? I have Atlas track and switches, but I have no numbered switches so nothing here to look at. I believe there were some problems with the very early Atlas switches, but I was not in the hobby at that time so I am not sure exactly what the problems were?

Have you checked the traction tires on the problem engines. since the problem seems to be power, perhaps the traction tires and spacing of the trucks is causing the issue. perhaps the trucks are loosing contact with the switch which will cause a power loss.

The problem with older Atlas switches is they used a very fine wire to connect the different center rails, and one overcurrent episode would burn out the wire and leave that rail unpowered. The fix was to run a more robust jumper. We had to do a lot of those on our club layout.

The TMCC N&W J stalled & blinking lights, at the spot just passed where I replaced the Atlas switch with a straight. Sounds like there is a signal issue in that spot that does not affect the PE Berkshire. I think I'm going to try to jumper wire the switch I removed as per Johns suggestion, and place it back where it was. But jump from where to where?

MartyE posted:One of these is at least a start. Available pretty much in any hardware store.

I love mine. No tool box should be without one.

gunrunnerjohn posted:Still waiting on the Mianne benchwork, I've been led to believe it takes several months. Tim has my money, I just have to wait until he ships it.

I ordered my Mianne benchwork at an October York Meet ... it was delivered 2.5 months later. The time did cross the Holiday Season which, I'm sure, made a difference.

In any case, it was worth the wait. ![]()