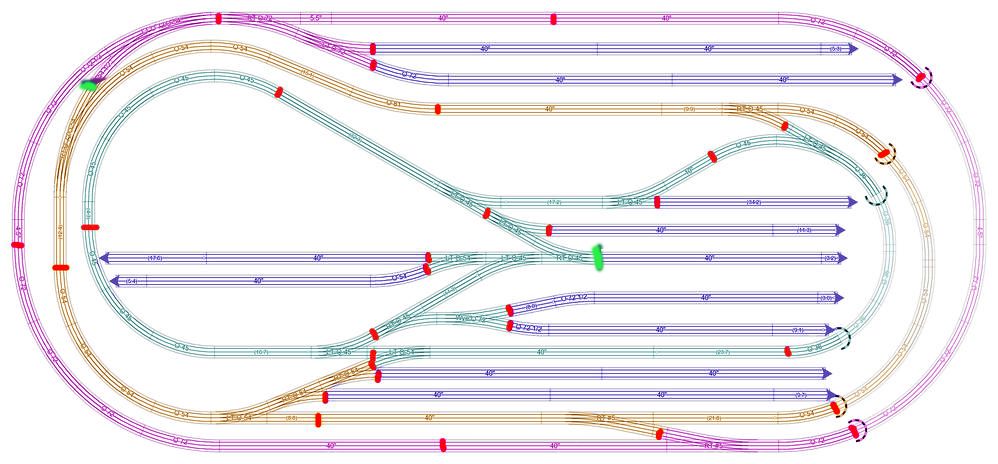

I have finally reached the home stretch of my layout design. I've got the track plan, but now I need help with the wiring plan. Here is the layout:

I'll use Atlas track, and a have a ZW-C with 4 180W power bricks to power it, as well as a couple CW-80s. I have TMCC/Legacy as the control, and will be running conventional at times. What I want is help on how to proceed, to learn from those that do know, what are the best practices.

Here is where I was thinking of making my blocks. I'd put the plastic rail joiners on the center rail at each red mark, and on one of the outer rails at the red marks on the 3 loops so that I can use Atlas's signals.

My 1st thoughts early on was to make a control panel that had a 4 way switch for every block so that I could set any track to be controlled by any handle on my ZW. This way I could run a conventional locomotive between loops without keeping track of more than one handle, but that's going to make a rat's nest of a wiring nightmare. But recently I've began to realize that I as I get more Legacy locomotives, I really like using the remote to drive, and have plans to upgrade most of my locomotives to TMCC, but then I also still have a couple locomotives that I don't want to upgrade, so running them between loops will be a pain. What does everyone else do about this? I was thinking a handle for each loop, and the 4th for the spurs, using a CW-80 for the lit buildings and another CW-80 for accessories, or I could power spurs with the same handle as the loop they are on, and use the 4th handle for lights and accessories. But then I still have the problem with moving a conventional locomotive from loop to loop.