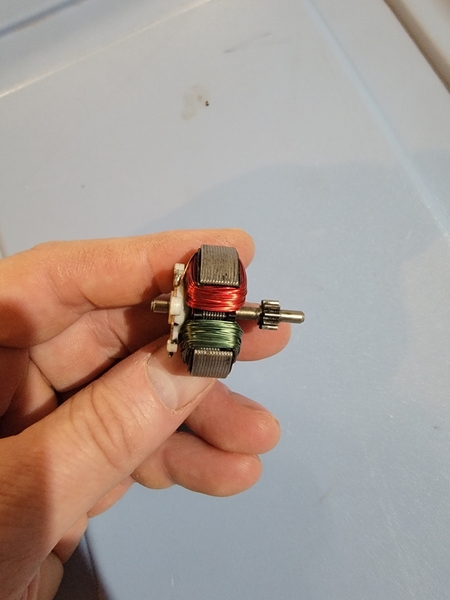

To start disassembly, turn the engine upside down and remove the 2 screws that hold the metal plate to the steam cylinders. That will allow you to remove the plate and the front wheels. Take careful note how things go together (pictures are a great idea...) so you can put it back together later. There may be a screw in the top of the boiler, or the motor may simply drop out, or there may be other screws available once the plate is removed. Check at the back (firebox area) for other screws. Once you have it out of the shell, post some pictures. Clear focused close-ups are good! That will help us with the diagnosis.

Chris

LVHR