Hi guys, just another NOOB, coming here with my hat in my hand, asking for help. I'm having an overload issue with this lionel train that belonged to my dad. It will run for 10-15 minutes, then the train just stops. The overload light on transformer then comes on. The light on locomotive is on, but the train isn't moving. If I move the switch on top of the locomotive, it will start moving again in reverse. I can then stop it and get it to run forwards again for another 10-15 minutes before it does it again. The tubular track is new. The transformer is 2 years old. I am using a piece of smart track for the power connection to the transformer, and have adapter pieces at both ends of it to cross it back over from fastrack to tubular. I have included pics of what I have, and will be very grateful to you all for any ideas or suggestions. Thanks.

Replies sorted oldest to newest

Is that a Universal motor or a DC motor?

Jon ![]()

@Dan Walker Welcome to the Forum. It may be helpful to post the Model Number of the Locomotive. It should be stamped on the bottom, but that information in the picture is out of focus. Is this locomotive from the mid-late 1970's?

@Dan Walker how did you connect the terminal track to your tube track? I know Lionel makes a transition track for that but it looks like you linked the tube track directly to the Fastrack.

From the pictures, it appears to be a 6-8602 AC motored locomotive with a 2 position e-unit (yes, that cab number and design was carried on through with DC motors and whatnot, but I see all the markers of the original AC type setup). Now, as @ArtsModelTrains stated, mating FasTrack directly to tubular track without the proper transition pieces is asking for trouble. Lionel offers FasTrack transition pieces http://www.lionel.com/products...ition-piece-6-12040/. Now, I don't see those being utilized, but it does appear that you are using the Menards transition pieces: https://www.menards.com/main/g.../p-1477981296131.htm

FYI, Tubular track commonly uses either the Lionel CTC or LTC lockons, but I don't recommend you immediately make this change as what you do have should work:

Also, a track plan such as the one you have pictured can benefit from multiple track connections to the transformer, but again, we are getting ahead of ourselves...

As for the overload condition, which seems to be the principle issue, there are a few things that immediately jump to my mind:

- Looks like you are using Menards track - at one point, there were some pieces that had poor center rail insulators which would either be consistently shorted out, or intermittently short out. A good close inspection of each piece may be warranted (yes, it is tedious, but got to start somewhere!) to find the one or more pieces in need of repair. If the train is misbehaving in the same area, that can be a clue. You could also start with a small oval, and gradually add pieces over time as the existing pieces prove themselves.

- The transformer is on the smaller side in terms of power capacity, but it should be able to handle just this locomotive without overloading.

- The locomotive may be drawing excess current if it hasn't been properly lubricated and serviced causing the overload condition.

There is a lot to take in here, so don't hesitate to ask clarifying questions! Welcome to a great forum with lots of great experienced O gaugers!

Thanks guys. Yeah, those are the transition pieces I used. (Bought from Menards). Do you think, using the other pieces you've listed would work better? Would it be smarter to just swap over to a tubular track connection? Thanks for helping me out with this. This track is actually set up at our local airport. I am building a layout that the kids can enjoy while waiting for their flights to board.

@Dan Walker posted:Do you think, using the other pieces you've listed would work better? Would it be smarter to just swap over to a tubular track connection?

Not the first step i would take...

@bmoran4 posted:I don't recommend you immediately make this change as what you do have should work

I did give you some things to try, mainly reviewing the track pieces you do have and looking for the probable defect...

@bmoran4 posted:As for the overload condition, which seems to be the principle issue, there are a few things that immediately jump to my mind:

- Looks like you are using Menards track - at one point, there were some pieces that had poor center rail insulators which would either be consistently shorted out, or intermittently short out. A good close inspection of each piece may be warranted (yes, it is tedious, but got to start somewhere!) to find the one or more pieces in need of repair. If the train is misbehaving in the same area, that can be a clue. You could also start with a small oval, and gradually add pieces over time as the existing pieces prove themselves.

- The transformer is on the smaller side in terms of power capacity, but it should be able to handle just this locomotive without overloading.

- The locomotive may be drawing excess current if it hasn't been properly lubricated and serviced causing the overload condition.

ok. Any tips on what I should be looking for as I inspect the track? I'm assuming it is just signs of arcing? Are there other telltale signs that the connections are bad?

Check the paper insulators for defects and for loose joints. A thread here shows a picture of a broken paper insulator (removed from tie for visibility)

@Dan Walker posted:ok. Any tips on what I should be looking for as I inspect the track? I'm assuming it is just signs of arcing? Are there other telltale signs that the connections are bad?

Welcome to the forum!

Has this engine and transformer worked with other track?

Does it happen when just running the engine, or when pulling a large number of cars?

Do you have any other engines that run on this track without the overload issue?

I am just trying to narrow this to a track vs locomotive problem.

As to the Menard's track problem, I believe a few of them had center insulation that wasn't great. If you look at where the center rail attaches to the tie, there should be a piece of heavy paper or card stock between the rail and the the little clamp pieces on the tie. You can do a visual inspection. Even better, and definitely tedious, is to use an electrician's multi meter, and check for continuity between the center rail and each tie. If the meter is a beeping, you got something that needs a fixin.

Also, the connections on the bottom of that piece of fasttrack should be inspected. The need to fit snug. A loose connection there could be drawing extra current which would also cause a trip after a few minutes like you are describing. There's lots of ways to connect to tubular track, a lock-on being tried and true.

Attachments

OK, Thought I would give you guys an update, since you were so helpful. I replaced all of the remaining Fastrack with menards tubular track. I used CTC clip ons (3 of them) to connect power to track. The widest gap I have now between clipons is about 12 feet. I ziptied all the track joints together today. I haven't run continuity checks yet, but it is my next step. Train will run for a bit, then stop. If I switch it into reverse,(via the switch on locomotive) it often starts back up again, but only for a short while (60 seconds or so). I get intermittent overload light on transformer sometimes when train stops. I'm wondering if part of the issue isn't the locomotive now. I have never cleaned it, and to the best of my knowledge it has never been cleaned. Do any of you have any links to good "how to" videos on how to clean and lubricate a 6-8602 locomotive? Thanks again for all your help.

12 feet between clip-on power supply is, in my opinion, way too far. You should have power supply every 6 feet or so.

You have to remember that power doesn't just flow up and down the tubular track freely. The metal track itself resists the power flow and restricts it. Long track sections like 12 feet can bleed the power down very significantly.

And, I have learned the hard way, that brand new track needs to be cleaned first. Manufacturing processes can leave films and residues.

Clean the tubular track thoroughly, and this can help alot. If you don't have anything handy, you can use 96% strength rubbing alcohol, and a good clean cloth with a tight weave, like an old undershirt, and run the wet cloth forcefully up and down the rails. This alcohol is flammable, so make sure you rub it off as you go with a dry cloth, and let it dry.

Using a weaker solution of alcohol, such as 65%, has too much water in it and can rust your tracks.

And, I'm not sure if you are running a separate set of wires to each clip-on or not. You can't just run one set to the first clip-on, and then run another set from the first clip-on to the second, and another from the second to the third. You need a separate set of power wires running to each clip-on.

If you do all of this, then you will probably have eliminated the track as an issue, and then you can move on to separately eliminate the engine and transformer.

Definitely start that process by cleaning and lubing the locomotive.

And, not trying to upset you, but you definitely have a bargain-basement transformer, and no transformer lasts forever.

Mannyrock

Let's see if we can eliminate the track as a source of your problems.

Take the train off the track.

Disconnect the transformer from the track.

Set a multimeter to ohms or resistance.

One lead to the center rail, the other lead to one of the running rails. You should have zero conductivity (very high or infinite ohms). If you are showing some value, you likely have at least one piece of track with an insulating problem. Break the loop in half and retest. Keep breaking the track apart until you find the offending section(s). Tedious, but necessary.

Also, inspect the track joints. They need to be tight to minimize electrical resistance at the joints.

Clean the track, even if it looks clean. Do NOT use Goo Gone!!!

If everything checks okay with the track, then the engine is next.

Good luck!

Chris

LVHR

12 ft spacing is more than good enough to not have the problem you are describing. I seriously suspect there is something wrong with the locomotive.

Same questions I had before, do you have any other motorized equipment, and does the same problem happen when you run those?

Do you or can you get alligator clips? ( yes I know the center rail lead is not hooked up in this picture)

If so, turn the loco up side down on a towel or something soft, make sure it is secure. From the transformer, clip the hot lead to a roller pickup and clip the ground lead to the metal frame.

I used blue instead black for the arrow for better contrast.

Turn the transformer op to what you normally run at, and just let the wheels spin in the air for 15 minutes or however long it normally take for the problem to arise. Since there's no load this is a guaranteed means to that the problem will show up, but if it does show up you can probably stop messing with the track. As stated before if no other equipment is doing this on the track, it's likely not the track. Another method is to set the engine up on rollers and let it run for a while.

One caveat is I can't tell what type of reversing unit this machine has from the pictures. From your description of a switch on the top, I surmise its an older style that tends to get gummy. Since these are spring and gravity operated you may want to block it wood/books/etc and let the wheels face down while spinning.

Attachments

Does the transformer get hot too? Does the motor in the loco seem excessively warm, if you can't hold your finger on it, it is too hot. Are there any hot spots in the track, test by feel. Amazing how an AC powered train will work with track short issues up to a point, the transformer will just pump the amps into the problem. Your unit at 18VAC and 80 VA is about 4 amps of current, so it could be feeding the loco and a track issue too.

Thanks for the replies guys. I will test locomotive like you described.

Hooked the jumpers to the locomotive today. It had exactly the same problem it had when running on the track. it ran noisily for a few minutes, then stopped. I don't know if this link will work, but I posted video I took of it on Facebook. https://www.facebook.com/DanWa...ts/10221225480014295

OK -- then the problem is most likely not the track. Time to seriously look at the locomotive.

Thinking if you have another engine to run it would work on your track until the other is fixed perhaps.

I don't have any other engines. Wanting to see if I can fix this one. Anyone know of any How to videos on disassembling and troubleshooting these locomotives? I'm hoping it just needs bearings and brushes, or something simple like that.

To start disassembly, turn the engine upside down and remove the 2 screws that hold the metal plate to the steam cylinders. That will allow you to remove the plate and the front wheels. Take careful note how things go together (pictures are a great idea...) so you can put it back together later. There may be a screw in the top of the boiler, or the motor may simply drop out, or there may be other screws available once the plate is removed. Check at the back (firebox area) for other screws. Once you have it out of the shell, post some pictures. Clear focused close-ups are good! That will help us with the diagnosis.

Chris

LVHR

Fyi @Dan Walker your video isn't showing. Something about permission to view it.

Like the others said, time to start disassembly and posting clear pictures. I don't think anyone wants to direct you to a repair video until its clear what you are working on. There are a few different variations of what could be under that shell.

Attachments

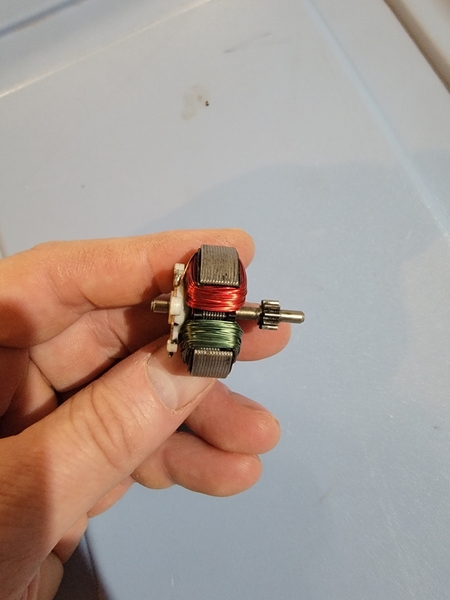

So I am not skilled at reverse units, (commonly referred to as e-units since they were initially known as electronic reverse units.) So I will let someone else speak on that portion.

What I will say is the brushes look quite used. That would make me think the commutator would be very dirty.

The brushes are the little round graphite rods held in place with the springs that are soldered in place.

Carefully remove the three screws holding that round looking plastic plate with the wires attached to it. Lift it up and be sure not to loose the brushes in the process. Move it to one side and remove the rotating portion of the motor.

The surface the brushes rub on will look black. Get a red rubber eraser and scrub the gunk off. Do not use anything metal or abrasive.

Put the rotor back in. Make sure the brushes slide nicely(almost never an issue) and reassemble. Try the loco again.

Here are some similar parts from an engine I converted to a can motor. You can see the cover plate, brushes, and motor rotor. The bronze looking plate is the part you clean. A red rubber eraser works fine. If you have a hobby shop nearby some new brushes wouldn't hurt either.

That's my 2 cents for tonight.

Attachments

Based on your video that thing is squalling for lubrication and probably the main reason for your issue. Brushes look fine but the armature could probably use a cleaning. There are plenting if youtube videos on how to clean the armature.

Agreed. After watching your video, you definitely have lubrication problems. You'll want to add a drop of oil to both ends of the armature shaft, and the rear driver where the drive rod attaches.

Given that your engine was the very lowest-priced steamer that Lionel ever made, it will be way more sensitive to track, wheel, and roller dirt than a more robust unit. That engine's rollers and ground points will be VERY touchy... especially in a public setting.

Jon ![]()

Good advice here.

I did all of this last year on a 70 year old Scout engine, and afterwards, it ran like new!

Mannyrock

I agree with the above analysis. Clean it, lube it, put it back together and see how it runs. Don't over do it with the oil and grease. Grease on the gear teeth, oil on the pivot points. Use just enough to keep things moving smoothly. Too much turns it into a dirt collector. Do pay attention to the rollers. A small drop of light oil at the pin is good. Use a needle oiler if you have one. If the problem persists, then we need to look at the E-unit. With any luck at all, that won't be necessary.

Chris

LVHR

I have found that after I oil it, it is best to immediately let is sit for a day on a paper towel. Any excess oil on axels, grease drip, etc. will soak down into the paper towel. Otherwise, it will end up on your track rails and wheel tires.

Mannyrock

Follow lehighline's post above and "Don't over do it with oil and grease". If you have to let it sit on a paper towel, you have over oiled it by way too much!! In lubricating trains less is better.

Thanks for all the help guys. It is VERY much appreciated. Do you guys have any tips or tricks for getting the brushes to stay in place while putting the cover back on? Been struggling, trying to get everything lined back up. Brushes just keep popping out when I try to put the cover back into place.

Put the brush plate on first w/o the brushes. (BTW, did you clean the inside of the brass tubes where the brushes go?)Then use something like a small dental pick or other hook to raise the wire in the tube just enough to slide it to the side. Do NOT pull it up any higher than you need to clear the tube! Drop the brush in and move the wire over.

Chris

LVHR

Patience is all I can say. I have heard rumors of trying to keep them in the brush plate with something like a thin metal ruler or piece thin plastic and then sliding it out after one or two screws are started. I haven't tried this, but it should work.

UPDATE: Per everyone's advice, I took locomotive apart and cleaned everything and then reassembled and oiled and greased it. It now runs GREAT! Thanks so much for all the help. It is very sincerely appreciated.

Dan that's what makes this forum so great. Helping others fix issues and learning at the same time.

Your Welcome

@Dan Walker I am glad to read it worked out. I hope that loco brings you joy for years to come!

![20211124_101327[1] 20211124_101327[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/157688391228471353/filePointer/157829273443120866/fodoid/157829273443120861/imageType/MEDIUM/inlineImage/true/20211124_101327%255B1%255D.jpg)

![20211124_101327[1] 20211124_101327[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/157688391228471353/filePointer/157829273443120866/fodoid/157829273443120861/imageType/SQUARE_THUMBNAIL/inlineImage/true/20211124_101327%5B1%5D.jpg)