I've posted elsewhere about two ATSF locos that were planned but cancelled, which I have decided I want to run on my layout and so must build. A number of folks have asked for photos, etc., as I go along rather than just when done, including my showing the learning experiences (i.e., what doesn't work). I decided rather than update those three other threads I would unify everything here. I will add to this thread from time to time as I make progress of run into more "learning experience."

The first of these two locos was a 6-4-4-4 steamlined cab-forward, 100 mph-cruise postwar oil-fired steamer to pull the Super Chief - think of PRR T-1 turned around with a diesel type cab forward and you pretty much have it, at least as pictured in E.D. Worley's Iron Horses of the Santa Fe Trail. Photo below is of it as of this afternoon: Made from a scale TMCC T-1 and a MTH Premier dummy F3 cab, front truck from my spare/junked loco parts box. Most of the heavy work is done: the model looks almost exactly like the drawing in the book except for sun shades over the cab front windows, which I will add later. The only mod required beyond cosmetic bashing was to move the wireless coupler to the ofter end of the loco. It runs well with the front truck behaving itself and tracking well. A lot of detail work and rather involved paint to do yet (Warbonnet, of course!). I may replace the T-1's tender with an all-new body rather than try to modify this one: the two drawings on have of this show it with what looked much more like the tender from a UP Veranda turbine than an oil-version of this one.

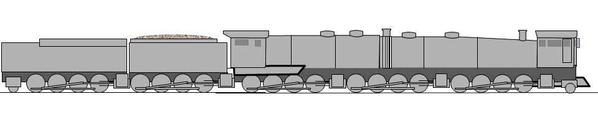

The second loco is a much more challenging build. It is a Pentuplex - a 2-8-8-8-8-8-2 proposed just before WWI by Baldwin for Santa Fe in 1913. Had the war, USRA standards, etc., not intervened it might have been built: the longest, heaviest, steam loco ever with more pull that two Mallets. It was to have cab forward and a cab in the rear, too, and was to have a flexible joint in the boiler as well as a flex-jointed, bendable tender. This is my drawing of what it would have looked like, based on various books and internet references to it.

I posted a picture some days back of the running chassis. I never had any doubt I could make it work well (chassis from five Lionel RTR 0-8-0 locos). It is the smoothest running loco I have ever seen, too: forty-four wheels and twelve center pickups don't lose connectivity with the track for even a millisecond for its five flywheel motors. Photo and video below show it with experimental body #1, crude cardboard but it serves for the experiment. aI discuss what works and what I have learned for try #2 after the video.

I always figured the real challenge would be building the loco body, from scratch, so the two flex joints work, and this is proving to be the case. The cardboard body is crude and ugly cardboard and paper , and the boiler is too narrow and way too low - deliberately so, so as to really test clearances and space needs inside it. This experiment is semi-successful. The tender's flex-joint works well enough: I know how to engineer that now. At the joint one tender has a rounded end (when viewed from above) that fits about an inch into the front of the other and rotates within it. it works well enough.

The boiler joint is not satisfactory. I expected this but I had to try the obvious first: here, the two sections of the boiler are firmly attached to driver sets, the front to the leading driver set and the rear to the third driver set. They meet over the middle of the second driver set, and my hope was that their ends would place nice with one another so that I could just install a ball joint there to connect the two (it doesn't look like a ball exactly but that terms gets the idea across). It does not work: the two boiler ends bounce and twist around, not alot, maybe only 1/4 inch at times, but enough relative to one another that with my ball joint connecting them, shake and twist their respective driver sets too much. Next, I will try to "float" just one of the two halves of the boiler: I will leave the rear boiler secton firmly attached to its driver set, as now, but the front boiler halve will not be firmly attached to the leading driver set, instead, it will pivot at its front and its weight supported at that point and by the ball joint. I should get that done by next week.