Awesome. That's what I suspected. That's a great idea!

Updated 1/4/2022:

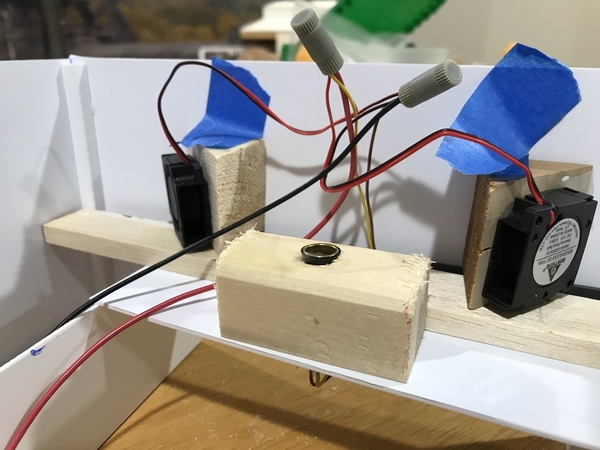

This morning we have been doing a little "wind tunnel" testing. I rigged up the two micro-fans and the Seuthe smoke unit to see if we could generate enough smoke volume to replicate the "action" on the Charging Floor of an Open Hearth furnace. Here's my first configuration of fans and smoke unit.

We are getting a minimal level of smoke, but it's not very satisfying. ![]()

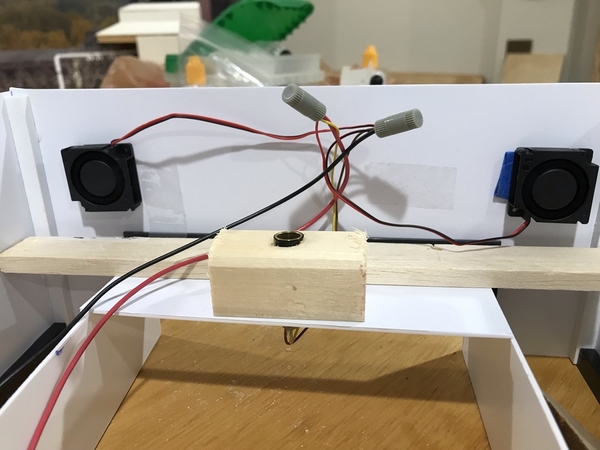

The fans, although pretty small, are moving the smoke rapidly away and dissipating it too efficiently. So I changed their placement, as shown below.

I think that generates a tiny bit more smoke, but I am going to try putting a cover of some sort over the structure and see if we can't build up an accumulation.

More when (if) I know it.

George

Attachments

George what an ambitious project. How many square feet of layout space is this going to take up?

As I have posted before I am a native of Youngstown in the day only second to Pittsburgh in steel production. Born just after the the War, raised there and matured there. Recall miles or so driving along Republic Steel on Poland Ave. Driving by US Steels Ohio Works, at night driving on the other side of the river of YS&T's Brier Hill Works. And near Republic Steel Haselton Furnaces (eight blast furnaces) near center street.

Back in my HO days thought steel mill would be great, but the space needed.

About two years ago or so O Gauge magazine featured a steel mill layout(s). If recall correctly one was 8X8 and the other something like 6X8. Walking around the perimeters comprised the steel making and rolling actions and processes. He has a slag dump area with lighting effects. Also a furnace tap into a molten steel car with lighting effects.,etc.

Am anxious to see the finished product.

Ron

@PRRronbh posted:George what an ambitious project. How many square feet of layout space is this going to take up?

As I have posted before I am a native of Youngstown in the day only second to Pittsburgh in steel production. Born just after the the War, raised there and matured there. Recall miles or so driving along Republic Steel on Poland Ave. Driving by US Steels Ohio Works, at night driving on the other side of the river of YS&T's Brier Hill Works. And near Republic Steel Haselton Furnaces (eight blast furnaces) near center street.

Back in my HO days thought steel mill would be great, but the space needed.

About two years ago or so O Gauge magazine featured a steel mill layout(s). If recall correctly one was 8X8 and the other something like 6X8. Walking around the perimeters comprised the steel making and rolling actions and processes. He has a slag dump area with lighting effects. Also a furnace tap into a molten steel car with lighting effects.,etc.

Am anxious to see the finished product.

Ron

Ron,

Yes, it is very ambitious. Two responses to your first comment:

- My father often said to me, "George, your eyes are bigger than your stomach".

- The motto of the Hershey Aquatic Club (both my boys were members) is: "Go big or go home!"

OK seriously, the area for Weirton Steel is roughly 7' x 10'. The Open Hearth is roughly 38" wide x 70" long. There is a separate area for the slag dump at Standard Slag (also a Youngstown, OH based company).

I feel your sense of loss regarding the demise of steel production in your hometown. Weirton is barely a shell of itself. ![]()

George

Updated 1/5/2022:

Yesterday, I tested the Seuthe smoke unit both with and without enclosing the oven. It didn't do very well, so I ordered an MTH smoke unit. I hope (and expect) that it will put out a lot more smoke.

Also tested the string of 4 Mega LEDs (warm white) for the interior of the Open Hearth oven. They are terrific and will fit the bill perfectly.

Today I used The Chopper to cut 1/8" ABS angle to the proper length for diagonal braces and ventilator supports for the roof trusses. Hopefully, I'll be able to get the roof trusses completed this week. They are a bit tricky and tedious and I want them done and out of the way.

More when I know it.

George

Updated 1/6/2022:

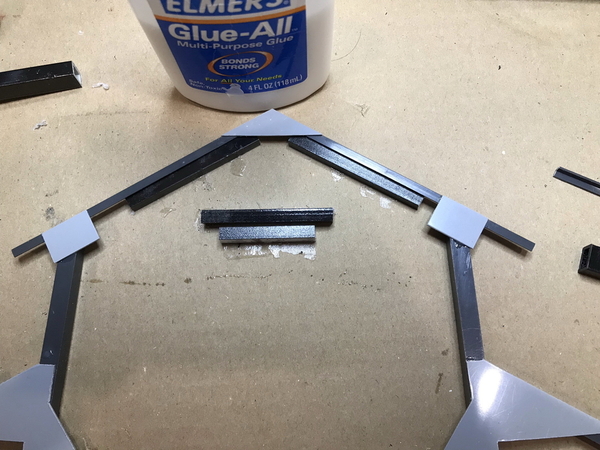

Finally got myself off the dime to start working on the Open Hearth roof trusses again. Turns out I needed to adjust the jig first. The positions of the uprights were a bit off. I am using some Plastruct rectangular rods for guidance; they are glued to the cardboard.

In this photo I've glued the gussets to the main roof diagonal supports.

And so it begins!

More when I know it.

George

Attachments

Updated 01/07/2022:

Worked on assembling roof trusses today. I had forgotten just how involved this really is – it’s a real kabuki dance. There is a definite sequence to be followed if I want to speed up production. While lying in the jig, each truss has 2 sides, which I will refer to as top (facing upwards) and bottom (facing downward). With the 30” long bottom truss already built and those 6 gussets in place in its middle, the rough sequence of assembly involves:

- Positioning and gluing the uprights to the gussets in the long bottom truss using the jig. Care has to be taken that they are 90 degrees to the bottom truss prior to gluing and clamping in place.

- Using the measurement on the diagram, position gusset #6 on each of the uprights. Glue and clamp into place. This is the spot where the main roof diagonal support meets the upright.

- Using the jig, construct the ventilator roof supports. I usually build both sides of this sub-assembly.

- Use more gussets to mate the ventilator roof support to the uprights.

- Add the main roof diagonals, their supports, and any cross-bracing.

The photos should help you visualize this. This one shows the uprights being built.

This is the ventilator roof support (bottom half). You can tell its the bottom half because all of the gussets are visible.

Here's one of the braces for the main roof. Another main roof diagonal will cover most of the gussets.

Finally, here's the second completed roof truss. Only 7 to go! They are propped against the spray booth. Eventually, they will get a coat of flat black and some weathering - colors TBD.

More when I know it.

George

Attachments

Nice progress!

@Mark Boyce posted:Nice progress!

Thank you! Believe it or not, I was hoping to be finished with all 9 trusses by today. Oh, well. It's a bit trickier than I expected.

George

Updated 1/09/2022:

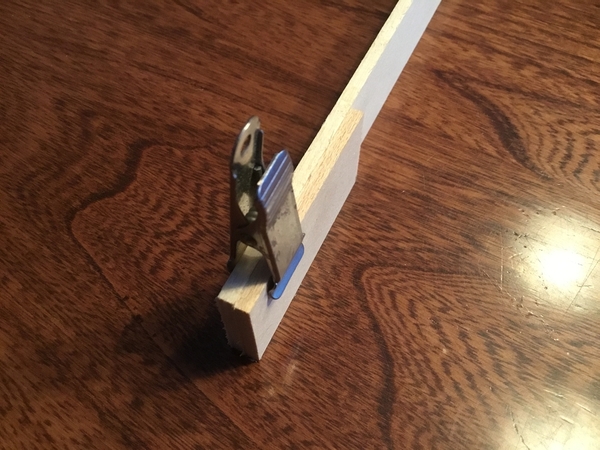

Still working on trusses. But I found a use for some alligator clips. The fact that they are narrow allows me to get them itno spots where my wider clamps don't fit. Does anyone know of a source for low pressure clamps of this type? Or maybe reverse tweezers are the ticket.

More when I know it.

George

Attachments

Looks good. Do the alligator clips leave teeth marks on the plastic?

These might be to wide or not open far enough. Got them at Micromark. The wood strips are 1/8 thick by about 1” for reference. They only open about 5/16 of an inch. They look to be about 1/2” wide. I would think some of the tweezers used for soldering would work.

Attachments

Mark - I haven't seen any marks in the plastic so far

Dave C - I appreciate the suggestion, but it's the width of the clip that is problematic. I need the clamp to get into tight corners (see photo for what I mean).

Anyway, thank you for chipping in on this issue.

George

Updated 1/11/2022:

Been working on the smoke unit issue for Open Hearth ovens - discussion over on the Electrical sub-forum. I did manage to get the MTH PS1 smoke unit working on 15VAC. It's an expensive solution, so I'm re-thinking my options.

Some additional supplies and tools arrived today - CA glue needle applicators, 1-2-3 blocks, and miscellaneous items. I am still waiting on a large order of Plastruct for this building.

I also managed to complete another roof truss earlier today. That's going a bit slower than I'd like, but we are moving. Each roof truss has 37 pieces, so it takes some time to correctly assemble one.

That's 3 down, 6 to go.

More when I know it.

George

Attachments

Those are looking awesome! Reminds me of the building I used to work in.

Hey George, did you see Alan Graziano's steel mill project?

@BillYo414 posted:Those are looking awesome! Reminds me of the building I used to work in.

Thanks Bill! We will keep on pushing.

George

@Dave NYC Hudson PRR K4 posted:Hey George, did you see Alan Graziano's steel mill project?

I sure did! It's a very nice blast furnace. I have been following that thread.

George

Updated 1/12/2022:

Got another roof truss done - that makes 4. Also determined that my newer 12VDC power supply was not putting out the correct amount of voltage. It's being returned (under warranty) for replacement. I verified that my new MTH smoke unit will work at 12VDC, so that is good news.

More when I know it.

George

Updated 1/14/2022:

I have a new acquisition for the Panhandle - one (of the 2 expected) P & W buses. I picked up 2 Corgi 1:43 buses at a prior York and commissioned Tommy Gilbert (Tommy Gilbert's Hobby Shop, Gettysburg, PA) to convert them into the masterpiece you see below.

Needless to say, I am very excited by this!

George

Attachments

I never thought I would be impressed by a bus but wow! That's sharp!

Super looking!

George,

Tommy did a wonderful job. Thanks for sharing.

Dave

Attachments

Wow! It looks like 5 in that photograph.

@Mark Boyce posted:Wow! It looks like 5 in that photograph.

Yep! Steubenville was a hopping town in that time. It was the shopping center for a lot of eastern Ohio.

George

@PRRronbh posted:Is Dean strolling around town in this pic?

Ron

You never know. Maybe he is...giving Jerry a tour.

Updated 1/22/2022:

No photos, but some progress to report.

- Got the repaired power supply back and it's functioning correctly. It drove both MTH smoke units and the Seuthe unit adequately. Amazing what the proper output voltage will do, isn't it?

- Truss work continues. Good thing I bought the CA debonder. Unfortunately, it's getting too much use as I correct mistakes.

What was that? Measure once, glue twice?

What was that? Measure once, glue twice?

- Still waiting for a major Plastruct order to arrive at the hobby shop.

- Temperature was -2 F this morning. I think I'll stay home and keep working.

More when I know it.

George

Taking the dog out with a mighty head cold was a doozy this morning.

So it's you that has Plastruct all backed up ![]() I went to buy some parts a few days back and they said it's all back ordered haha

I went to buy some parts a few days back and they said it's all back ordered haha

@BillYo414 posted:Taking the dog out with a mighty head cold was a doozy this morning.

So it's you that has Plastruct all backed up

I went to buy some parts a few days back and they said it's all back ordered haha

All part of my evil plan for world domination.

George

Attachments

Updated 1/23/2022:

Sometimes with reflection comes clarity (not always). I have been wrestling with some aspects of the Weirton Steel Open Hearth mill. In particular, I have been debating changing its size (it’s gotten both bigger and smaller) over the past 2 weeks. The building will have at least 3 smoke units and they need to be reachable for service. Tracks inside and near the structure also have to be accessible in case of derailments or other problems. And I wasn’t comfortable with the placement of some auxiliary structures.

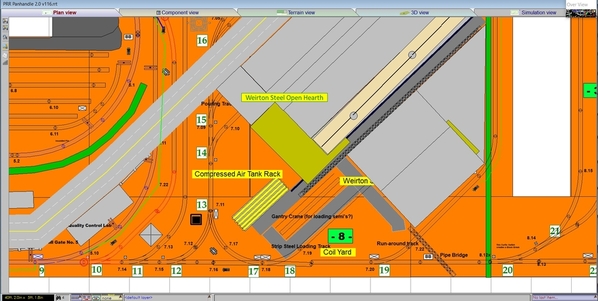

Here's the "before" track plan.

And here's the "after" plan.

So after much thinking, here are the changes and decisions:

- The Open Hearth has changed from 60” in length to 52” long. Mill width has gone from 36” to 38”, with the 2 extra inches going to the “Lean-To” portion that houses the smoke stacks, electronic circuitry, and power supply.

- The entire mill will sit on a single piece of 5/8” plywood. This will make it easier to transport.

- The number of smoke stacks has increased from 3 to 4. Two are dummies.

- The size of the ovens in the interior has gone from 20” to 11”. There will be 4 (Nos. 14, 13, 12, and 11) versus 2.

- The main roof area between furnaces 14 and 13 will be removable.

- The entire front of the building and the protruding Cinder Yard will be one piece and removable so that visitors can see into both sides (Pouring Floor and Charging Floor) of the building.

- The number of sidings entering the building will be reduced from 2 to 1. That siding will remain along the northwest edge of the building and serve the Pouring Floor. This results in the elimination of Switch #14.

- The area in front of the mill will be cleared of all auxiliary structures, with the compressed air tank structure moving to the front of the neighboring Strip Steel building. The area in front will become a large access hatch disguised by something (probably a parking lot or truck staging area for the Strip Steel).

- The Strip Steel will become a bit less wide. The building will be used to disguise a large access opening underneath it. This will allow me to reach the side of the Open Hearth and service all smoke units.

- The Strip Steel spur track will be moved down towards the southeast edge of the building. That means moving Switch #18 further east (towards the backdrop).

More when I know it.

George

Attachments

That is a lot of thinking, George!! My brain hurts! ![]()

@Mark Boyce posted:That is a lot of thinking, George!! My brain hurts!

Yeah, me too! ![]()

Kid: "May I be excused from class?"

Teacher: "Why?"

Kid: "My brain is full." ![]()

George

Updated 1/25/2022:

I completed roof truss #7 (of 9 full size ones). No. 8 is in the jig and underway.

My brain wasn't hurting enough, so I did some more thinking and made these additional decisions and refinements of previous decisions: ![]()

- The Cinder Yard portion of the Open Hearth (the extension on the southeast side of the building) has been extended to be 18.75” long (75 s’). The Cinder Yard is the portion of the building at the left side of the photo below. This will require 3 additional “half-trusses”. Fortunately, we have enough ¼” ABS angle pieces and gussets to accommodate this modification. The Pouring Track will run straight through this section.

- The width of the Strip Steel building has been reduced from 7 bays to 5 bays. Each bay is 6.25” (pilaster center to center) and the total width is 31.25” (125 s’). The building was originally a yellow brick (that's the color it will be on the layout). I believe it was repainted sometime in the 1960's. The rightmost bay will be an open door to accommodate a spur into the building. All other bays (bottom and top floors) will retain their original design – 2 rows of 4 Tichy 20-pane industrial windows. Except for the bench work supporting the spur, most of the building will cover an access hole. The entire building will be removable as one piece, which will allow me to reach the spur as well as the side of the adjoining Open Hearth. This will be needed to service the Open Hearth Lean-To, which will hold the electrical and smoke components for that structure.

- The spur will extend inside the building and curve across its back diagonally, permitting an occupancy of at least 7 gondolas for loading. I am also toying with the idea of extending a gantry crane outside the open bay, but that's not prototypical. Jury's still out on that idea.

- Between the two buildings will be a road between 2.5-2.75” wide (max 11 s’). Above the road will be a pipe bridge. The supports should be placed on the Strip Steel side of the road (above the height of the Strip Steel). The bottoms of the supports should be protected by bollards and / or painted yellow. Feeder pipes will extend from the pipe bridge to the Open Hearth’s Lean-To, depicting the use of blast furnace gas by the OH. The pipe bridge will run the length of the Strip Steel, terminating at the divider.

More when I know it.

George

Attachments

How far outside the building would the gantry crane be able to run?

@BillYo414 posted:How far outside the building would the gantry crane be able to run?

On the prototype building, it didn't. As far as I know, I never saw a gantry crane on Weirton Steel property. That isn't to say there wasn't one.

When it comes to overhead, or more correctly, bridge cranes, every mill I worked in (Tin, Strip, Blooming) had at least several. I have 2 to build for the Open Hearth, which will be visible. I'm not sure a fantasy gantry crane is high enough to make the build list. There is a long, long way to go on this layout. I might put this idea down to thinking out loud.

George

I was just curious how far it would extend if you did add it to the structure. They can look pretty cool because you can see everything. That also means you can hide anything on the back side haha but still, I was just curious.

@BillYo414 posted:I was just curious how far it would extend if you did add it to the structure. They can look pretty cool because you can see everything. That also means you can hide anything on the back side haha but still, I was just curious.

If I were to do this, I would extend the rails about as far as the switch. Like I said, this is a "nice to have" but there are way too many "gotta haves" in front of it. ![]()

George

Updated 1/26/2022:

I finished the last of the major roof trusses tonight for the Open Hearth (9 in all; each with 38 pieces).

George