I am hoping somebody here can help me out for I don’t understand Relays and electrical stuff very well.I need help in putting safety relays in my layout I have 4 blocks in my layout. I would like to run pusher engines.So my problem is If my engine derails in block 1 block 2 needs to stop sending power. I have dcs also and 1 180 watt brick to each block. Can somebody help me. Thx and possible diagram that I could follow if possible thx again Rick

Replies sorted oldest to newest

As I see it, you need to define the qualifying event(s). Then, we can determine how to detect that event(s). And then what to do about it.

For example, if a pusher drives cars into a swan-dive from a lifted bridge, the cars are certainly derailing! You'd want to immediately cut power to the engine...but it is electrically difficult to detect that cars are derailing since the power to the engine does not change much.

If you (your eyes) are the detector in all cases, then I'd think pressing the DCS red E-STOP button is the simplest way to remove power to blocks.

So to use your example, the qualifying event is a derailment in Block 1 which should instantly remove power from Block 2. What if the derailment is in Block 2? Should this remove power from Block 3? Or if operating CW instead of CCW should this remove power from Block 1?

The relay part (removing power) is relatively easy. And relays are inexpensive...maybe a couple bucks per relay. We can provide exact wiring instructions. It's defining exactly what you want to do that's the issue...in my opinion.

I had the same problem. Long trains with engines at both ends and across multiable blocks. I had a friend build this for me, this is above my pay grade. Works great, same system as you, DCS, 4 blocks and four bricks. All blocks shut down. So it is doable, just need someone to build this for you. This was built off site then installed.

PS when I asked this same question a few years ago on this forum I was told it can't be done.

Clem

Attachments

Clem, did you get a wiring diagram with that setup that you could share? Looks very interesting to me and just out of curiosity I'd like to see how it is wired, if that's possible. It might help the OP in duplicating the setup if it could also work for him.

I found these two OGR threads which I believe are what Clem K is talking about:

"can't be done" thread from 2015: https://ogrforum.ogaugerr.com/topic/track-blocks

"yes we can" thread from 2017: https://ogrforum.ogaugerr.com/...ong-trains-installed

Apparently, for Clem's system, the qualifying event is the breaker in ANY of the 4 bricks/blocks trips. This event is detected by the loss of voltage coming from that brick. The resulting action is power to all 4 blocks is removed. There are additional switches to reset/override this behavior.

I was thinking the problem might require coming up with a method to detect a derailment that does NOT cause a breaker to trip. That is, you want to quickly detect the derailment BEFORE it causes a problem (like a breaker to trip).

I do not have a wiring diagram, the gentleman that built it for me, just like some of you, likes to tinker around with electronic stuff.

clem

Need to add to posting I want all 4 blocks to shut down I would like something like Clem has

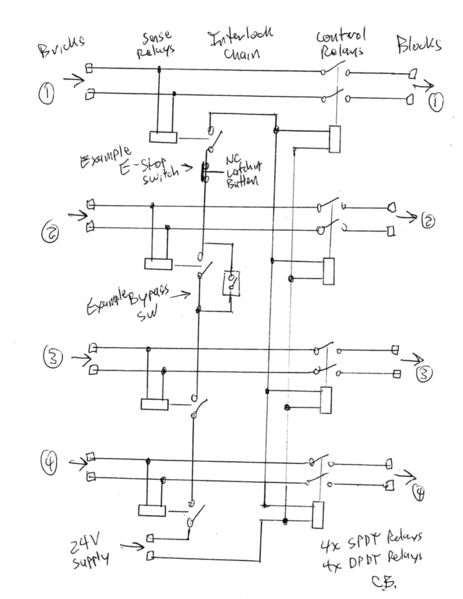

Here is a rudimentary circuit. There seems to more going on in the photo. The power for each block passes through a control relay. The set of control relays are driven by an interlock chain made up of a sense relay for each brick.

As shown, a bypass switch could be added to each sense relay to allow you to take that brick out of service. Also normally closed switches could be added into the interlock circuit to manually kill the blocks. These could be red mushroom buttons - they would need to be the type that latches where you twist the button to release it.

A small 24 volt ac power source is needed to drive the control relays. All relays are 24 V ac, assuming the 18 V from the bricks will work for these. Only Normally Open contacts are used on the relays.

Cam

Attachments

I was thinking sort of along those lines in the earlier threads Stan linked to, only I think I misunderstood the complete shutdown process Clem was wanting at the time. My thought with the working panel model in the picture was that it didn't seem to have enough relays? I am obviously still missing something here?

Maybe Clem's electronic friend will see this thread, have mercy on me and post a schematic for us...

Not quite clear why 12 relays are used in the photo. As Cam suggests, no doubt there's more going on than what's been posted.

Anyway, I like Cam's approach (8 relays). Should meet the requirements that have been so-far described.

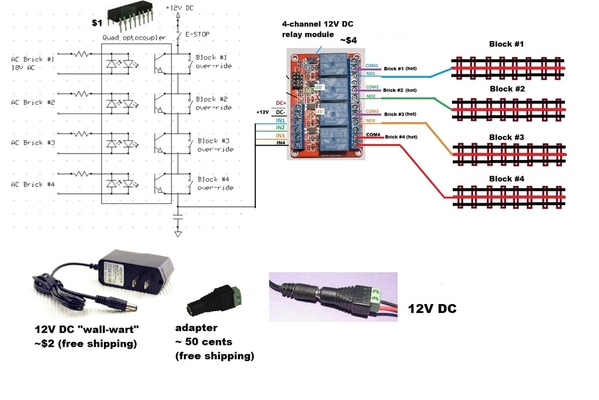

Here's a similar approach using 12V DC (instead of 24V AC) as the "control" voltage. I don't suggest this unless you're a determined DIY'er since it requires working with and soldering small components. But it can be done for about $10 out-of-pocket and only uses 4 relays. Again, this is posted in the spirit of kicking around ideas being that OGR is a discussion forum...

This uses low-cost solid-state optocouplers (vs. electromechanical relays) to detect the presence of brick voltage. The 4 optocoupler transistor outputs are connected in series so all 4 optocouplers must be triggered to present ~12V DC to the 4-channel relay module. This relay module is about $1/relay and the relays are 10 Amps. These are single-pole relays so this assumes the outer-rails of all the blocks are in common; Cam's diagram uses double-pole relays which switch both center and outer-rails. As Cam suggests, you can bypass/over-ride one or more bricks by placing a toggle switch at the output of the respective optocoupler.

Attachments

Has anyone thought of a way to sense when a car derails without tripping a breaker in the block?

I started with the premise of controlling both sides of each brick and not making any other connection. This is the most flexible but depending on how common is handled SPDT relays could be used to break only the hot side. The control relays must handle the full current output of the bricks. The sense relays only need to handle the combined current of the control relay coils. The sense relay coils are driven by the 18V brick outputs. The control relay coils could be any voltage, even DC. It would be possible to avoid the extra power supply by using one of the bricks.

Some time ago I sketched out a design to enable track power only if the TMCC signal is present. The command base was powered first. After a delay a relay turned on 120V to the bricks and transformers if the command signal was present. Then if the command signal dropped out the power was shut down. It used an Amperite time delay relay tube - I inherited a bunch of these in various voltages and delay times from a friend.

CJACK - Detecting a derailment that doesn't trip the breaker is a challenge. How to differentiate this from a normal current load. It might have to be a dynamic check looking for a sudden change in current? Maybe use a video camera with derailment recognition software. ![]()

PS when I asked this same question a few years ago on this forum I was told it can't be done.

Clem

Whats that quote, "When THEY say it's impossible or can't be done, someone in their garage is working on the solution" Or something similar to that effect....![]()

It's pretty easy to detect the command signal, the TMCC Buffer has a detection and monitoring circuit that shows signal strength. You could just duplicate that capability and add a relay to trigger the shutdown.

penn station posted:

CJACK - Detecting a derailment that doesn't trip the breaker is a challenge. How to differentiate this from a normal current load. It might have to be a dynamic check looking for a sudden change in current? Maybe use a video camera with derailment recognition software.

I was thinking maybe a short piece of rail outside each of the two outside rails for the wheel that's off the outside rail to bump against and trigger the shutdown...

John - I was thinking of hacking an R2LC. I could either just look for the 455kHz signal or do something with the detected command data. It would be connected directly to the base as I just wanted to see if the base was up and running. I am impressed with all your hard work on the buffer. Dale was a genius and it's hard to believe he is gone.

At one time I proposed making a TMCC receiver using sub-miniature tubes. I have loads of these in my vacuum tube collection. There is no valid reason to do this except, why not?

CJACK - that would work in some scenarios. Inside rails would probably work too. Perhaps use an accessory track.

I just found Dale's response regarding a tube based TMCC receiver. We were corresponding about the TMCC signal data encoding. This was from 2004.

You must be crazy!! Glass bottles in TMCC? Is that to get the full 'toob' sound that so many of the recording studio people talk about? Honestly, it sounds like fun, but WHY?? Then again, you could try Nuvistors....

penn station posted:I just found Dale's response regarding a tube based TMCC receiver. We were corresponding about the TMCC signal data encoding. This was from 2004.

You must be crazy!! Glass bottles in TMCC? Is that to get the full 'toob' sound that so many of the recording studio people talk about? Honestly, it sounds like fun, but WHY?? Then again, you could try Nuvistors....

Ah yes RCA Nuvistors, those tiny tubes in a tin can. Remember them well, especially since old tube testers didn't have those sockets so you needed adapters that plugged into a checker socket. Then there were the 10 (or was it 12?) pin glass bottles used in portable TVs...

Now I am showing my age. ![]()

Anybody remember the Raytheon CK722 Germanium transistor...?

cjack posted:Anybody remember the Raytheon CK722 Germanium transistor...?

Me, Me, ME!!!

My dad managed to locate one of them and gave it as a present (cost something like $4 in 1950s money). I then built a one stage audio amplifier attached to my Quaker Oats cylinder coil-cat whiskered crystal radio (later upgraded to a 1N34A germanium diode) to drive headphones. I then found plans to put in a transformer to drive a small speaker but the results were so so compared to headphones. I still have that little square can transistor somewhere as a memento to my electronics youth. Good old days.