The following is a puzzle for you electrical geniuses out there.

One of my goals for this re-wiring project was to eliminate a voltage drop and resulting slowdown/stop of my conventional locomotives in 1 spot and in 1 direction of my layout.

I share this here because I suspect I'm not alone and that many of us have, or had, similar voltage drops.

I will post a video of this later, but for the moment, will share some information about the voltage drop.

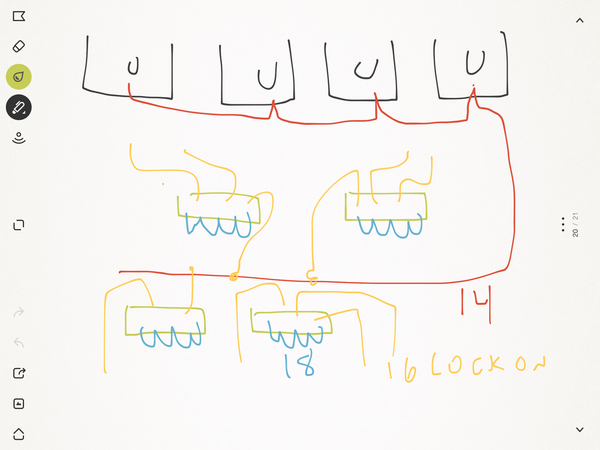

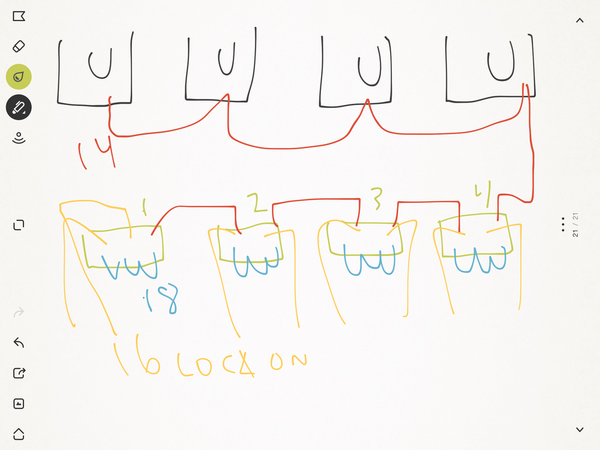

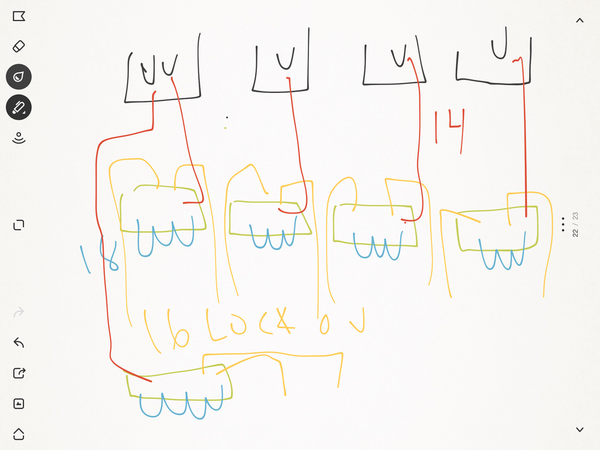

The location is in "My Little Town" at the far left side of my layout where 2 reverse loops (1 for the inner loop and 1 for the outer loop) converge, and where I have 4 crossing gates activated by insulated track sections.

The 4 crossing gates draw power directly from a ZW, not the track.

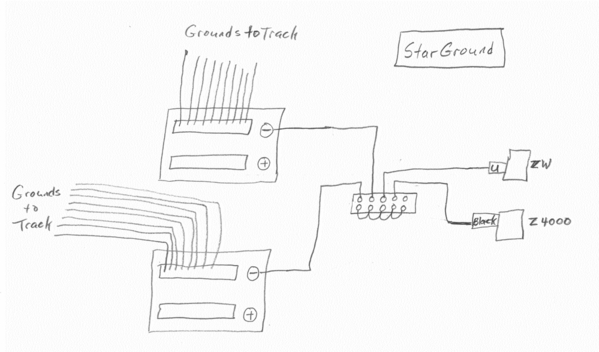

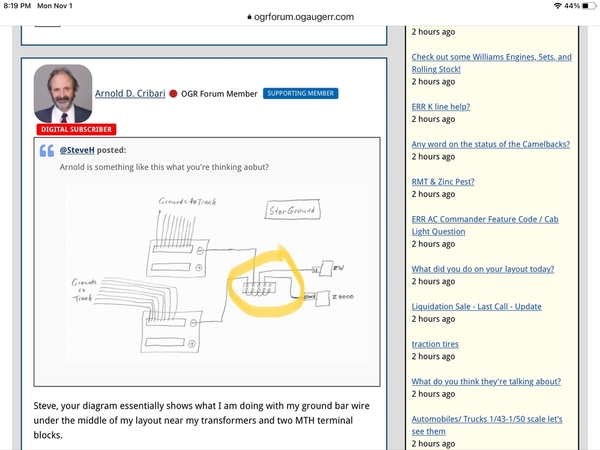

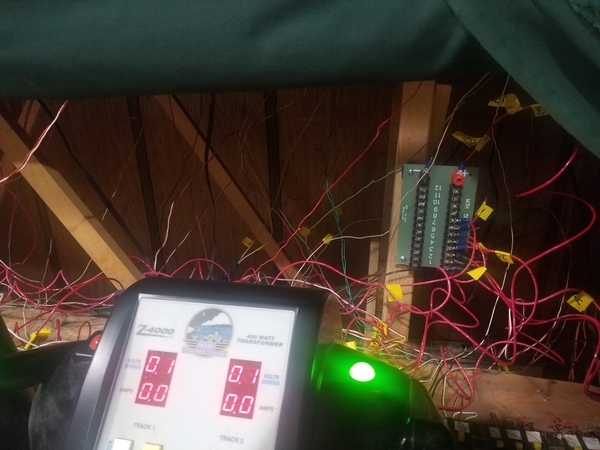

The reverse loops are independently powered by the throttles of a Z4000.

Now it gets interesting: the voltage drop only occurs on the reverse loop for the outer main loop, not the inner main loop, of the layout and only in 1 direction. Specifically, it occurs when the locomotive is running counter-clockwise, not clock-wise, through that reverse loop, and on, and in the vicinity of, the 022 switch. All 022 switches are independently powered by a 2nd ZW.

To be even more specific, this morning I ran a Williams NW2 diesel at 8 volts, and the amps were 1.0 amp that dropped to .7 amp near that 022 switch. The diesel slowed down, almost stopped, but did not stop, at that switch.

There is no slow down when running an MTH Proto 2 or 3 on DCS.

What is your answer to this puzzle?

Arnold