Arnold your continuing to make great progress…keep it going. I’m glad your working on a loop at a time and verifying your work as you completed it. That’s the easiest way to troubleshoot work that was just completed.

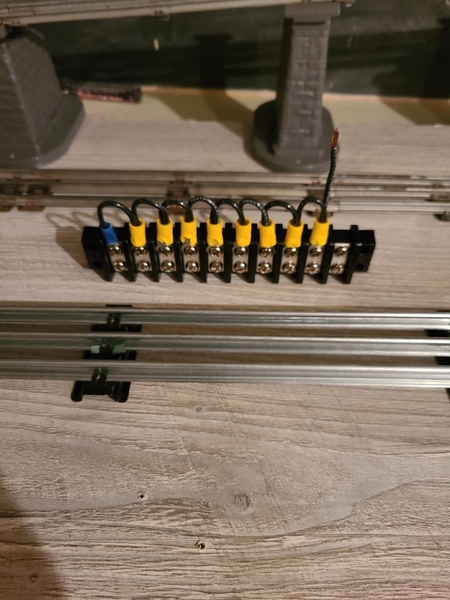

Yes, backing out the screws was necessary to loop around the easiest. The terminal block looks good and will serve you well. Is the tail you left long enough? How do you plan to daisy chain? Remember you have the mounting screws at each end, and you will need to double up the wire under the first screw on the new block.

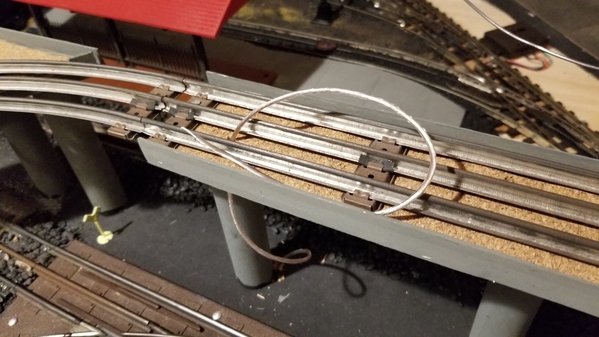

Question for you, how are you connecting the power lock on wire to the stranded wire running to you MTH block?

Keep making progress and the trains will be running in no time.

Rich,

Here is my same photo of my terminal strip with the bare 18 gauge copper wire threaded through the bottom screws, illustrating what I say below:

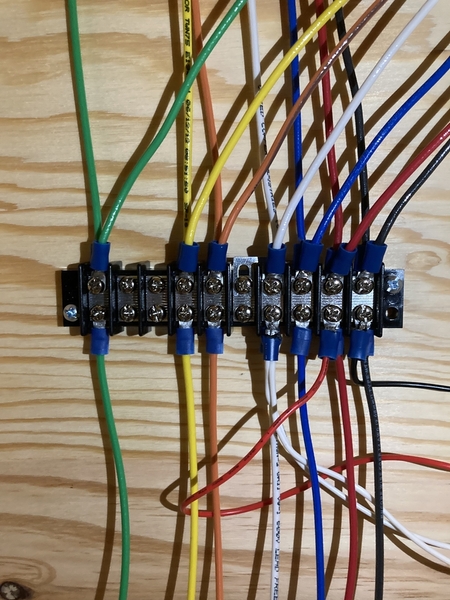

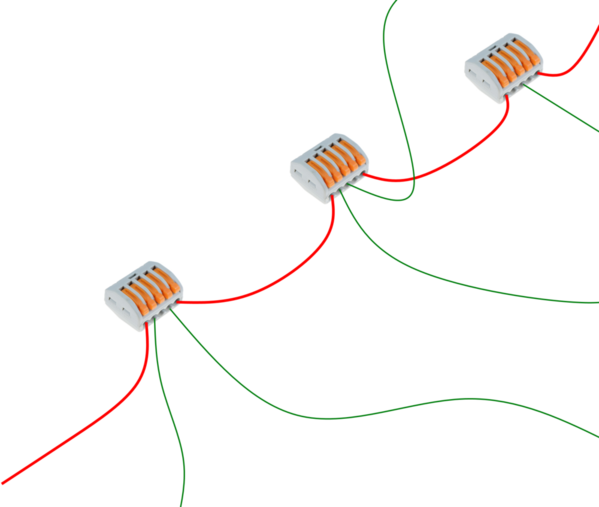

First scenario: my thought about daisy chaining, which may or may not work, is to connect the tail of the 18 gauge bare copper wire to a 14 gauge stranded copper wire that will run and be connected to a similar tail on the next terminal strip. I will make the connection by twisting, crimping and soldering the bare 18 gauge tail wire to the 14 gauge stranded wire, then put black electrical tape over said connection. I would do the same thing with the tail of the bare wire at the other end of the terminal strip.

What do you think of the first scenario?

Second scenario: I could also cut off the tails and, using a fork lugs, attach the 14 gauge stranded wire to the 1st screw on the bottom (doubling it with the bare wire) or on the top of the terminal strip, and do the same thing at the other end if the terminal stripm

The 14 gauge stranded wire will start from the U or ground (common) post on the Z4000.

What do you think of the second scenario?

Concerning your question about how I will connect the power lock on 16 gauge solid drop wire to the 14 gauge power stranded wire, my plan was to make the connection the same way. That is, by twisting, crimping and soldering the wires together and covering the connection with black electrical tape. Do you think that will work?

By the way, to be clear, 3 or 4 of the top screws on the terminal strip will be connected to the ground 18 gauge solid drop wires from the lock-ons in the vicinity of the particular terminal strip. The series of daisy chained terminal strips connected to the ground 14 gauge stranded wire will serve as my ground bus wire running the entire length of my 35 to 40 foot layout.

Arnold