I mainly collect pre&postwar "O" gauge trains, but recently acquired a #8 Electric and three passenger cars. I want to take on the project of restoring but upon taking the engine apart I discovered how different they are from O gauge motors.

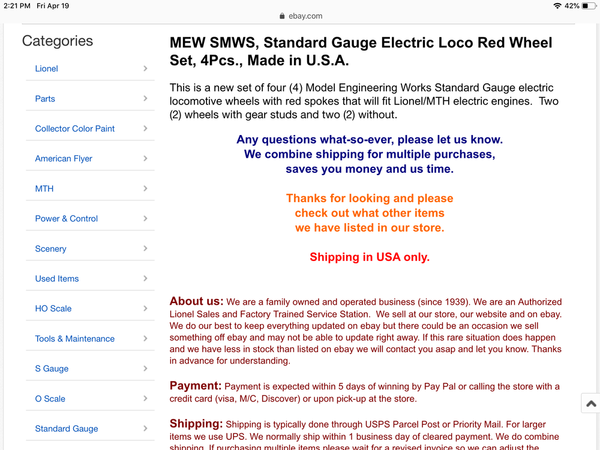

As this would be my first tinplate restoration in standard gauge, I was wondering if there are any suggestions on literature or videos that assist in rebuilding these motors. Yes, the wheels are dry-rotted and need to be replaced. I am considering purchasing a "Hobby-Horse" press...would that be a good tool for the job? I am familiar with the "library" on the Olsen's Train Parts website, but would feel more comfortable having some "how-to" advice on hand besides a parts diagram.

Thanks in advance for your helpful suggestions.

Greg