I've been doing some looking at various remote control sound options for rolling stock, I've tried several audio modules, and I have a couple different types still in the pipeline that I have yet to receive.

I started with the WTV020-SD-16P, but it was a disappointment. It's factory programmed for a specific function set, and they have all been for an MP3 player with just forward space, backspace, etc. I want one that I can select specific sounds. It also required AD4 files, so I had to go through a conversion raindance. The audio output was pretty weak, so I'd probably need an amplifier as well. If you are thinking of this application, I'd pass this one by. It's only positive attribute is that it's cheap, and you really do get what you pay for!

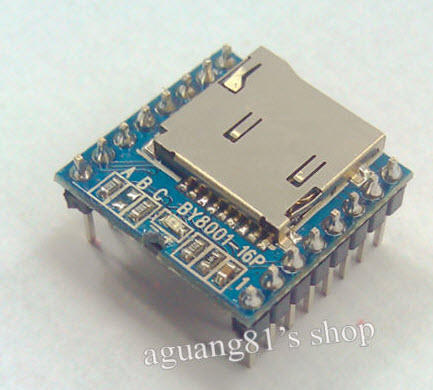

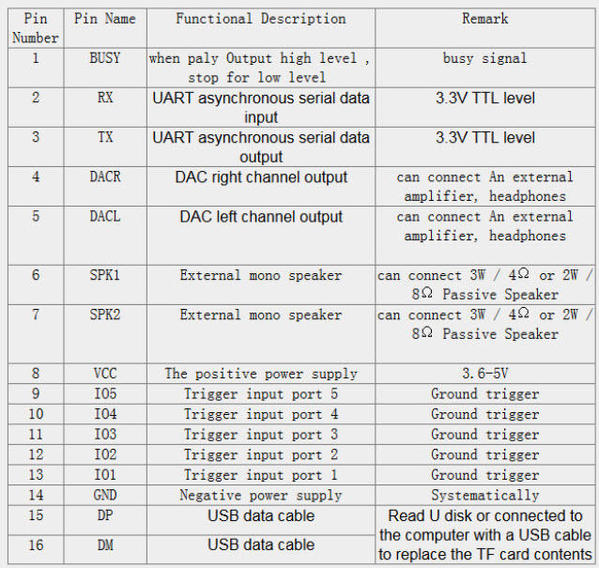

I then tried the BY8001-16P, and this one works much better. Not only is it a better quality board, but it has a better micro-SD slot and tons better audio! It has five pins that you can selectively ground and play any of the first five sounds on the SD card. It also accepts pretty much any MP3 file without any problems. You can move some function selection jumper resistors and change it to a computer controlled module, that will probably be the next experiment. With the computer control, you have access to any sound on the SD card, potentially thousands of them!

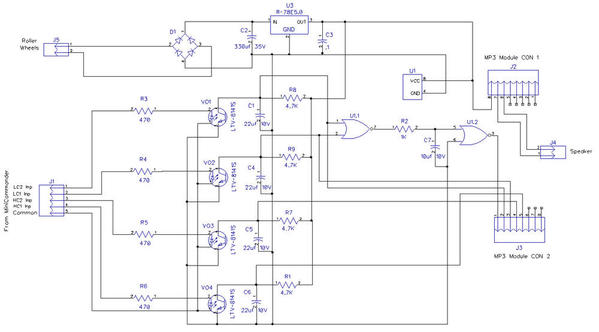

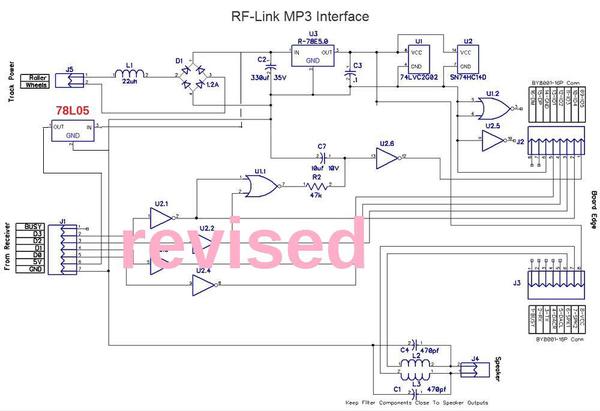

Having a worthwhile sound module, I set about pairing it with the wireless transmitter so I could remotely trigger sounds.

I already have a couple of these 4-Channel Wireless Remote packages, so I used one of those.

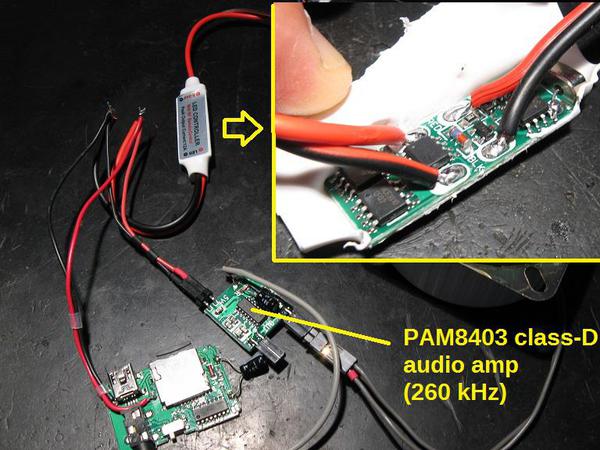

In order to interface these, I need a logic inversion as the remote receiver puts out a high signal for a button press, and the sound module expects the pin to be grounded to trigger a sound file play. I started by testing two channels, so I just added a transistor to invert the button press and trigger the sound module. Obviously, for the "production" unit, I'd probably use a single chip open collector inverter, but I didn't have one handy...

Here's the test setup.

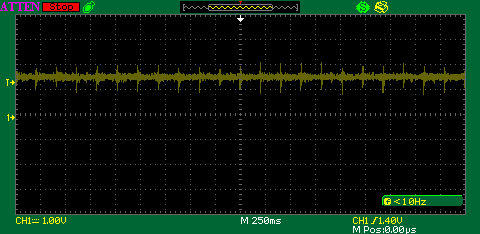

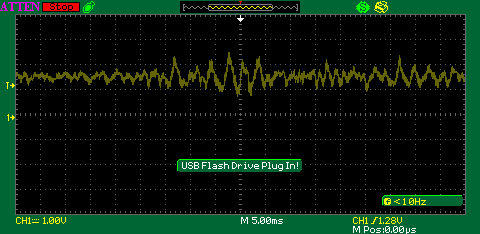

Some observations...

The module is pretty bulletproof, it's a very nice and well behaved unit. If you need high quality sound, this will certainly do it, and it will pump out all the volume you need as well.

The remote is OK, but I'm somewhat disappointed with the range. I found that both the transmitter and receiver needed a lot longer antenna for any decent performance. With my "clip lead" antenna extension on each, I got about 30 feet reliably, and spotty performance at 40-45 feet.

I'm still in the development stage, but I can see that this can work. ![]()

Any ideas for better transmitter/receiver options are welcome. Obviously, it has to be small as this whole rig is intended for rolling stock. My next step will be to put this rig into a boxcar and see how it behaves at the club layout.