I have recently acquired an American Models Chippewa 4-6-2 locomotive. this locomotive has metal wheels on the trailing truck. This is a beautifully done engine but I run on original AC Gilbert track. I noticed when I inspected the engine what looked like scratches on the back of the engine where the wheels contacted the chassis. When I ran the engine on my layout I saw where the trailing truck wheels were arcing when they contacted the chassis on the Gilbert curves. Has anyone else run into this and if so, how did you alleviate the problem? My thought is either smaller diameter wheels, plastic wheels, or to remove some material from the chassis, I am open to suggestions.

Replies sorted oldest to newest

Try removing (grinding ) a small amount of metal from above the wheels on the frame, dont mess with the wheels. then just touch it up with black paint , about 1-1.5 mm should do it. I have had the same thing happen with S scale brass engines. PS do you have the cars?

I have two observations from your picture. I'm a long-time O gauge railroader but have never owned any S.

The engine looks low at the tail end and the tender looks low at the front end. Neither looks to be sitting level. I think the front of the tender is low because the engine is pushing downward on the front of the drawbar. Before you do any grinding of the shell you might consider the following. If there is a spring between the chassis and the trailing truck, replace it with a stiffer spring or stretch the existing spring. This should raise the tail end of the engine and give the trailing wheels more clearance. Also examine the drawbar mounting at the tender.

MELGAR

@MELGAR posted:I have two observations from your picture. I'm a long-time O gauge railroader but have never owned any S.

The engine looks low at the tail end and the tender looks low at the front end. Neither looks to be sitting level. I think the front of the tender is low because the engine is pushing downward on the front of the drawbar. Before you do any grinding of the shell you might consider the following. If there is a spring between the chassis and the trailing truck, replace it with a stiffer spring or stretch the existing spring. This should raise the tail end of the engine and give the trailing wheels more clearance. Also examine the drawbar mounting at the tender.

MELGAR

I have the same engine in front of me and the dont dip, the engines in AF or High rail, were designed to run on their High rail/ scale track. as you can see in the photo the track is a bit off and that with the tighter, AF curves are causing the arcing , I have run S scale engines on flyer track and had some do the same thing. The one I have here #12 AC Flyer with w Chug and smoke has the same wear marks (but no arcing) under the fire box/ motor mount. You may want to call AM and talk to their tech guy. I ve seen this engine run on a layout made of AM track and AC power with no shorting. to amend my previous post , maybe try to insulate the underside of the fire box/motor mount, piece of contact piper to insulate it from the rear truck

Have the wheels spun on a lathe to trim them down to the diameter you need,….you can chase the tire, and the flange to keep them looking like they’re stock…

Pat

I agree with Melgar.

@Ron H posted:I agree with Melgar.

Yeah. I hadn't noticed it initially, but it certainly looks like it's not sitting level...

Mark in Oregon

Guys, ….look real close at the picture, …..it looks like Ray just plopped it on the tracks for a photo op,….the pilot truck is all slung in between the rails, and it doesn’t look like the rear tender truck is sitting on the rails correctly,….it looks like he was just taking a picture of the engine so we’d all know what model he’s talking about, ……name with a face sorta thing,..

Pat

That's a good point Pat; but the pilot truck being "down" like that should only serve to lower the front end, yet it looks like it's slopping down back towards the cab end...🤔 🙂

Mark in Oregon

There is a bit of optical distortion in the photo also; look at the roof lines of the cars on the back track.

Ray..........I have a southern crescent limited that I have run for many years without any problems. As you already know I also run on Gilbert track.

Since you bought it 2nd hand, I would examine it very closely to see if has been altered. Its probably a minor problem but will be difficult to solve.

Jackie

Ray.....If you decide to change the the back drivers I have a 2 set of wheels one with rubber tires and on without......

Jackie

Hi Guys,

Sorry but not been to the computer for a couple of days, thanks to all for input.

Dave: The removal of some material from the chassis is what I may address on the engine. I do not have the Chippewa cars but I do have a number of Polar Express cars that have been repainted in the Pioneer Express scheme. I am considering a repaint on this engine to Pioneer Express scheme, I'll attempt to add a link to Stream Style Graphics and a picture of PE locomotive.

streamstyle graphics - Bing images

Melgar and Pat, Good eyes, I did go back and check the track at that location, there is a sag in the roadbed that I will address but that is not the problem on the curves. the engine and tender sit level on level track.

harmonyards, The locomotive is on the track all wheels on the rails, a poor picture taken in to much hurry. I plan to remove some material from the bottom of the chassis.

Jackie, When I purchased the engine the man who sold it mentioned the contact points under the firebox, did not realize it was actually arcing from wheels shorting against the chassis. I put the engine upside down in my cradle and put a curved piece of Gilbert track on the wheels and that actually put the trailing truck wheels under the lowest part of the chassis. I think the original owner had similar problems with the engine and that is why it was not run much. I don't see a reason to change the rear set of drivers but I will be replacing the traction tire which are on the front set of diving wheels on the Chippewa.

Ray

Ray, your post caused me to examine my three AM Pacifics. I have a New Haven, a Southern Pacific and a Southern Crescent. All three are the same at the firebox and trailing truck area, the differences are in the cowcatcher and engine accessories.

These pictures were not easy to arrange so the clearance shows, I used the NH since it was handy. I have run this engine for a long time on Gilbert track laid on carpet, then on solid rail flex permanently installed on a layout. On the permanent layout the wheels never touch the chassis but it is very close. If I did not have generous vertical easements for the grades the wheels would make contact at the start of the grade. They do not make contact on any radius curve on perfectly flat track. The clearance appears to be about 1/32”.

The areas where the wheels have rubbed on the chassis are visible, there is also some minor pitting on the wheel flanges. This was from running on the floor layouts with uneven track.

In my opinion the easiest and best fix is to put a strip of electrical tape across the bottom of the chassis where the rub marks are visible.

Attachments

Corrective action completed. I took the picture prior to reinstalling the trailing truck. The engine runs fine, the tape is thin enough to not contact the flanges on level track.

This New Haven runs great, Goldinhands converted it to TMCC/Railsounds plus an electrocoupler. It pulls a nine car set of American Models NH heavyweights, six are their 70’ cars and three are their 80’ cars.

Attachments

Please let us know how well the tape holds up. The glue on electrical tape does not always hold well and often comes loose after a time.

I thought that may happen. I elected to just apply the tape as is. If it does not adhere long term I would put on an additional glue to hold it in place.

I think it would also work to attach thin pieces of plastic to the underside of the chassis with epoxy. Might be a more permanent fix.

Another idea would be to remove the rear truck pivot screw and insert a washer between the chassis and the top of the truck. Just a thought.

MELGAR

Placing a washer between the rear truck mount and chassis does not help. The washers just cause the nose of the trailing truck to point downward, they do not raise the chassis. Raising the rear of the chassis will just cause the rear drivers to loose contact with the rails, not a good thing. Looking closely at the above picture the mating joint between the chassis and the motor is visible. The tape is applied to the motor enclosure, the brass flywheel on the back of the motor is visible in the cab.

There are two other possibilities. One is to order scale replacement wheels for the trailing truck. The other way is to buy a set of the AM thin traction bands for the rear drivers. The Pacifics do not have traction tires, AM sells thin bands that can be glued in place on the rear drivers. Adding these traction bands changes the chassis angle on the track, raising the motor almost 1/32" at the trailing truck wheels. I have some of these and test fit them, I think they will also solve the problem. I am fine with the black tape I added.

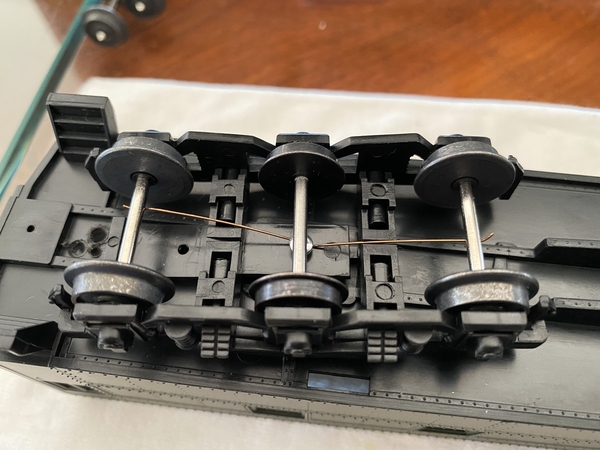

Here is a picture of an AM heavyweight three axle truck. The center wheels are scale, the outer wheels are high rail. The reduced height of the scale flange should work.

Attachments

I had trouble backing through Flyer switches & removed some metal from bottom of shell.( or the top of trailing truck ) I think the AM rubber drive wheels should be on the rear .

Bob G.