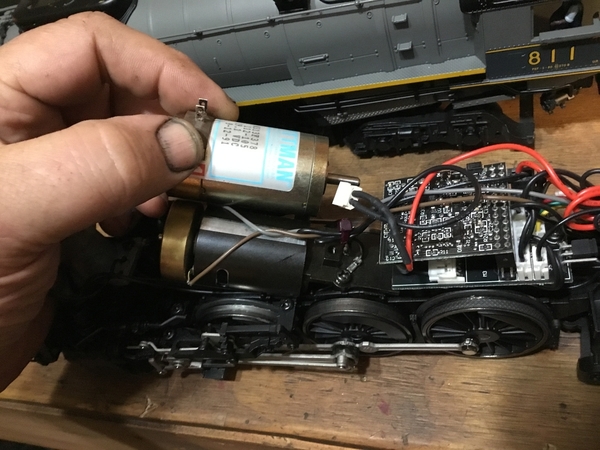

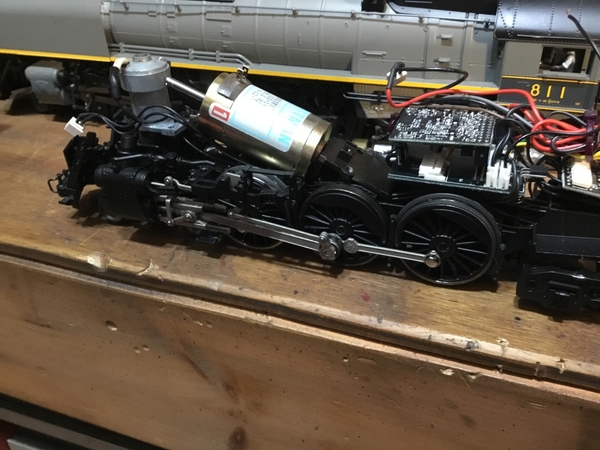

I’ve been looking into this project for a while, and I own a few examples of these finely detailed J1 class Hudsons. But like most of us that own these know, they’re way underpowered. I had one come into the shop for a bad chuff switch, and I got to looking around since the easiest way to access the chuff switch is to pop the motor out......I’ve had quite a few discussions with Pete ( Norton ) about these models and the subject of repowering always comes up....In there current state, my KLine Hudsons have been condemned to commuter duty and short milk runs. Pete has tried other motors, and I’ll let him elaborate on what he’s tried if he wants to....I believe he mentioned a Maxon motor. It appears that the 8300-8400 series Pittmans might be a fit for this project. In the pictures you’ll see what I mean...it’s gonna be tight, it’s going to be close, but I’m going to give it a go....what’s got to happen is, I’ll need to fabricate an adapter plate to mount the Pittman to the existing Mubachi 385 motor mount. I’ll need to transfer the worm to the Pittman. This is where I need a little help, and I’ll post a WTB ad on that forum as well....if anybody has extra motors they have from a cruise swap, or a dead motor with the worm, I’d like to buy a few to have spare parts for the first trial run of part manufacturing....I’ll need to bore the worm obviously to fit the Pittman...this is where I’ll want extras on hand to perfect this part of the swap....the motors from the scale Hudsons, and the Scale Mikados are the same according to Pete....I’ve done most of the homework as far as fitment goes, and there’s still some R&D work to do, but we’re factoring things like flywheel shapes and sizes as we go along...once we get a repowering “kit” together, I might be able to reproduce the parts as an option for some of these underpowered locomotives. And make them available. Pete provided me with the performance values of the 385, and comparing that to this model/family of Pittmans, it’s a significant increase in power vs. the 385.....there may be additional KLine locomotives like their scale Berkshires that can take advantage of this upgrade....this is still in its earliest stages of development, but if I can get my hands on some more motors to harvest the worm, I can make this happen. So if any of y’all have this motor with the worm attached, I’d like to buy them. Again, I will post an ad in the WTB to keep it official like, but I wanted everyone to see what I’m up to with this project, and it’s possibilities......and thanks to Pete (Norton) for your expertise and ideas. Some example item no.’s for these locomotives are K-3270, K-3690, & K-3615....if anybody has any other knowledge about motor interchangeability between these models, pipe up............Pat

Original Post

Replies sorted oldest to newest