Good news is, yours is the later revision. https://ogrforum.ogaugerr.com/...5#126718808002937895

"The first two digits indicate the month of manufacture and the second two digits indicate the the year of manufacture.

A serial number that begins with 0398 was mad in March of 1998, this is the first run of Z4000's ever made.

H1000"

Serial number on your Z4000 is: 121044289

Decoded = December 2010 serial 44289

Again, sorry for your troubles but yes, some of those early PS1 chipsets (it's the firmware on them, not so much that the board or chip is bad), are really picky.

I was surprised to watch your video and hear the ding and the increment to the double ding on the next button press.

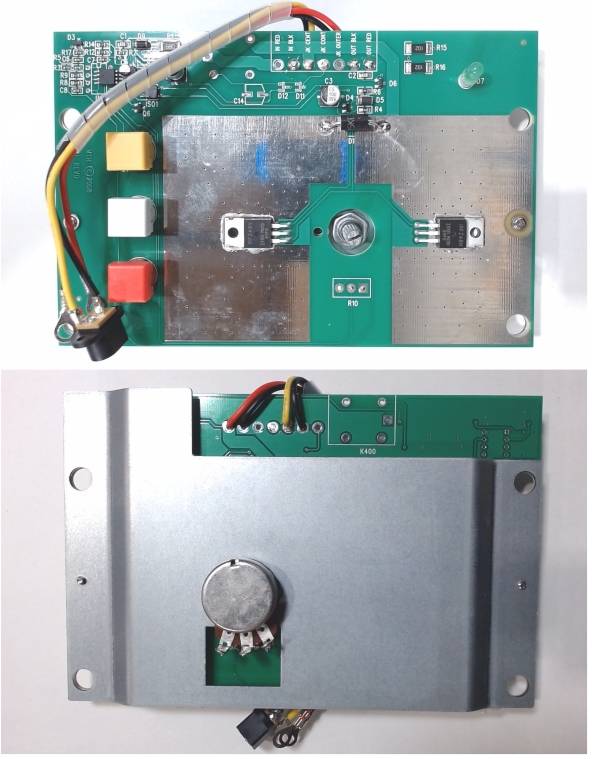

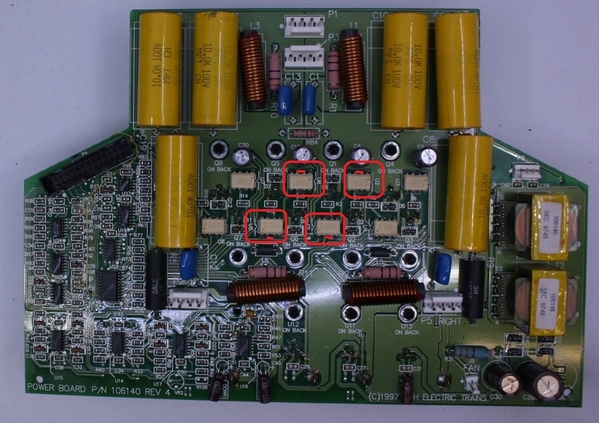

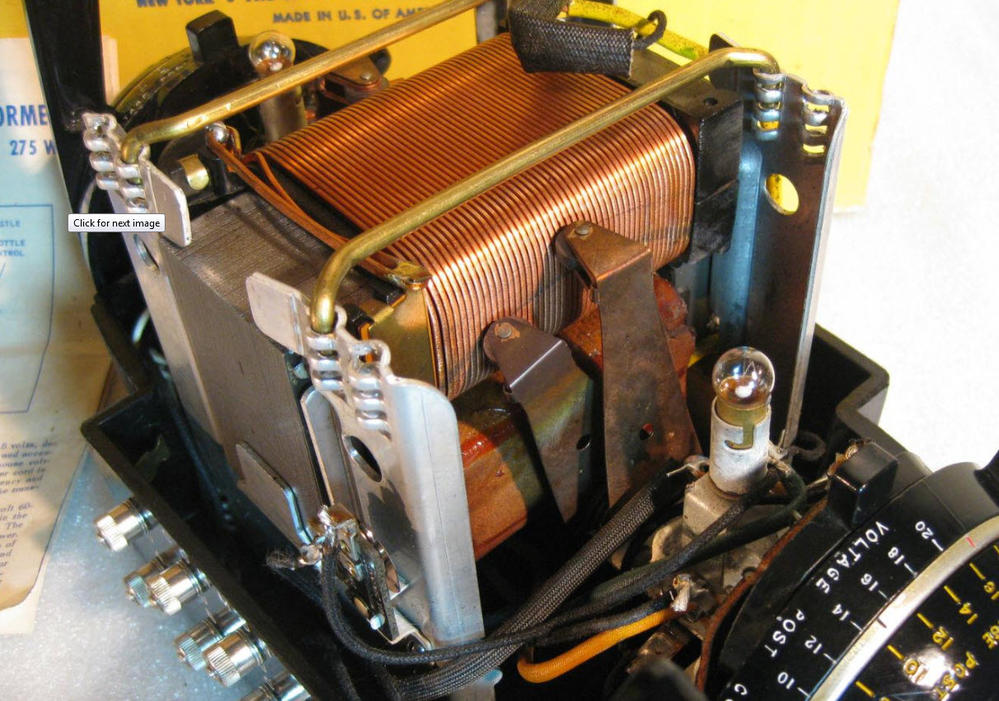

Being honest and working on these transformers, it's not like I have fully reverse engineered them but they somewhat contain a similar circuit (Zcontroller VS Z4000). The Z controller uses 2 MOSFET transistors to control the AC output and the Z4000 also uses MOSFETS. Yes, how they are controlled is much mroe complicated on the Z4000 but the idea was that more attempts to make it replicate true sine wave output.

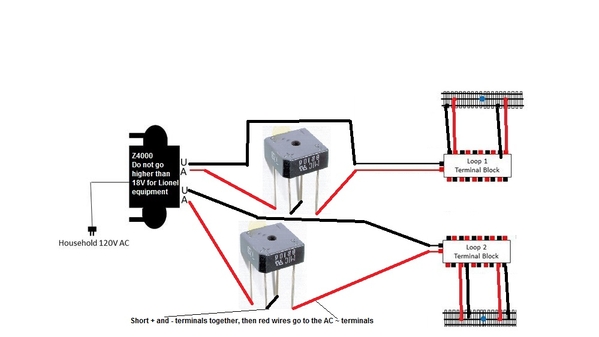

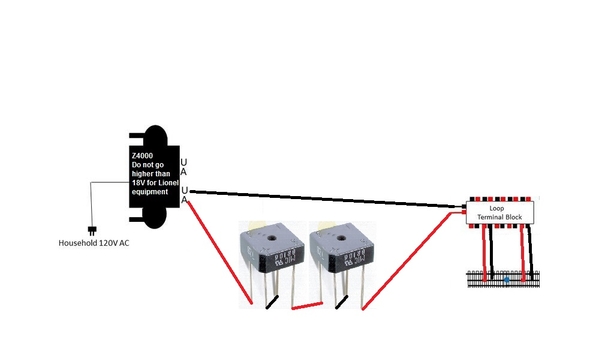

That said, one more test and part of the reason you likely wanted a Z4000.

Use the program button and attempt to factory reset this problem loco since with all the attempts we may have set settings by accident.

Make sure both handles are down and the loco is on the track. Also, since you have BCRs, what you typically do is power the engine for a bit (say 60 seconds) at 10V, then drop the handle, let the engine completely shut down- thus mostly retaining a charged BCR.

So again, you must start this with both handles down.

Press the black program button on that side of the Z4000

Now use the white whistle/horn button to increment up until 18 is displayed (down is the red direction button)

Now press the yellow bell select button

the transformer will power the track, wait a few seconds and the engine sounds will start up, then it will rapidly raise and lower the voltage on the track which should be registered as wooshes counting up to 18.

Then the engine should respond back with 3 dings and 3 dongs. *Just as a note, if it does not give 3 and 3, say 3 and 2 or 3 and 1 it's means the wooshes were missed- and you can fix that by incrementing up the count from 18 by using the white whistle/horn to say 19 or 20, then press select again which sends the 1 or 2 more voltage raise and lower causing more wooshes and then the board should respond back with the appropriate 3 dings and 3 dongs. If you go too high, and get more dongs like 4, just again, lower now to 18 (using the direction button to increment) and hit select again. The point is, there every once in a blue moon is a mismatch where the engine doesn't register or see the cycling and is off. The cool thing is you can increment without having to start completely over. That said, an overshoot does do the program sequence all over again to the lower count, but typically, it's just that you missed one or two and so there is an easy work around to properly get the 18 reset.

Once you get the 3 dings and 3 dongs, then hit the program button again and this ends program mode and powers down the track. Obviously wait for the engine to fully power down and give the fart sound.

Just trying to see if the one major function and a good reason to have a Z4000 for PS1 engines works for you. Reset programming using the program button is so much easier IMO.

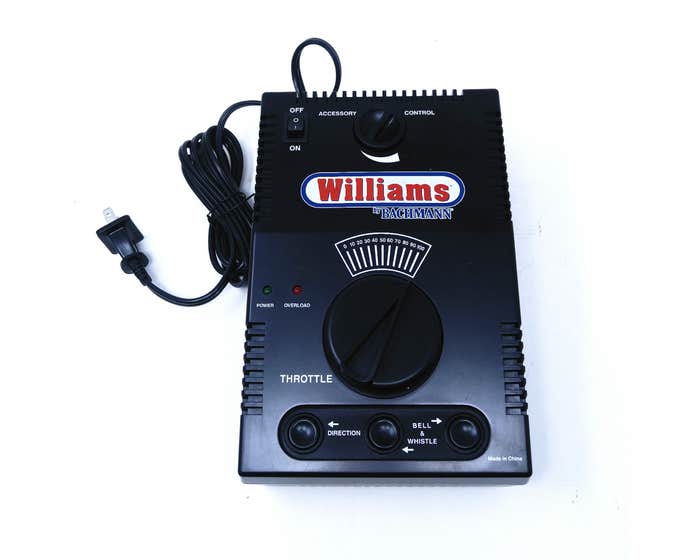

or a more modern 25 watt rated example that probably would fail

or a more modern 25 watt rated example that probably would fail