While I wait for the #10 to arrive, I have naturally been researching the above.

I read a piece on the "Tinplate Times" site where a guy restored a poorly painted 408E: he begins by saying he prefers to try to save the original finish if possible, and he was able to strip off the crappy re-paint and save the original Mohave finish.

I've decided to try that approach with the "10". It seems like the baked on original paint could withstand the stripper; depending on what's used, how long it sits and maybe a little luck. The terrible black (🤬) paint has to come off anyway, so using a stripper that will do the job quickly I think is crucial.

With that in mind, please share your thoughts and opinions. Thank you.

Mark in Oregon

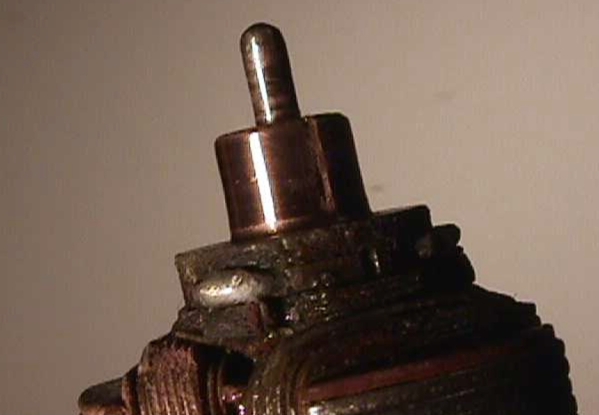

PS: after that, we can discuss the mechanism. The wheels appear to be okay (intact) so I'm hopeful. 🙂