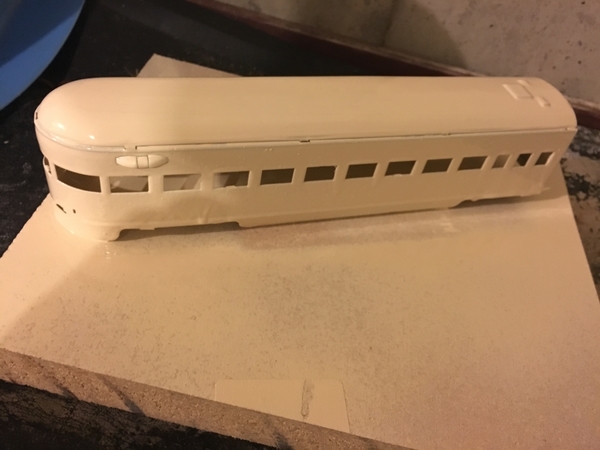

Finally, after just a little over a month, I can now post the completion of my American Flyer 312 restoration project:

Having already finished up the locomotive, it was the tender that required the most restoration work, both cosmetic and mechanical. Over the past couple of days, I applied Clover House dry transfer lettering, then sealed the PRR banner with Krylon Matte Finish (with which I'm pretty happy, I might add). After two coats of the Krylon had dried, I put red jewels in the tender marker lights, using black silicone caulking to hold them in place. I'd have used MV lenses, but after searching everywhere, I couldn't find any red ones available in the right size.

Next, I replaced the tender ladder extension with a repro from The Train Tender. The original had been broken off by Apefinger long ago, but installing the new one wasn't difficult.

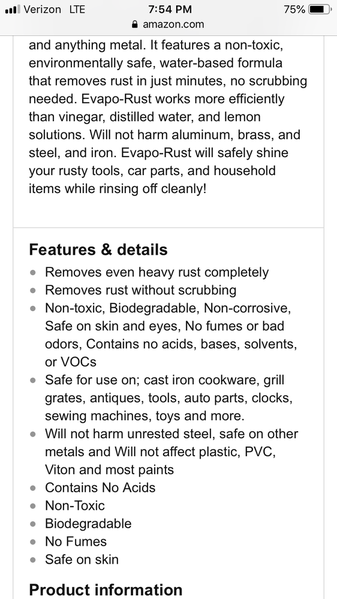

After that, it was time to finish up with the handrails. Apefinger had let them develop rust, of course, so I went over all of them with fine sandpaper, followed by crocus cloth, to polish them up. The final step was to shine and protect them with Simi-Chrome metal polish.

I know they're not scale thickness, but they look fine -- with the possible exception of the rearmost railings. To my eye, the overscale diameter of them really sticks out. Maybe at some future time I'll replace them with smaller-diameter brass railings; we'll see.

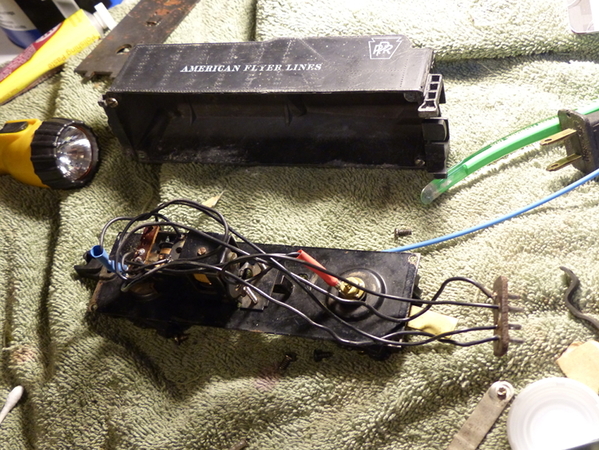

Once the tender shell was ready to go, it was time to screw it back on its frame. And here, Apefinger still had one final desecration to throw at me. Of the four self-tapping screws that hold frame to shell, only one was actually functional. Another was too small and would not tighten, and the remaining two were broken off altogether. I was able to back one of the broken ones out, but the other one will remain there, alas. I found proper screws in my parts box to fill the other holes, and the tender was in one piece again, with a working reverse unit:

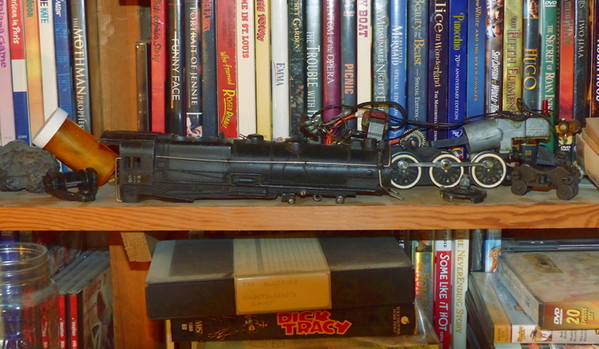

That done, it was time to finish up the final touch on the locomotive. Though I couldn't track down the correct MV red lenses, I was able to secure four green ones for the class lights. Again, I used black silicone caulking to mount them to the upper fixtures and the ones on the pilot beam:

You can't see the marker on the far side, but trust me, it's there. If anyone's still curious about the details, I painted the keystone using a couple of toothpicks, a jeweler's loupe and a lot of patience. The bell is NOS from eBay, polished with Simi-Chrome (I can't recommend that stuff highly enough; I've been using it for years).

ProTip: hand-held camera for an available-light closeup shot isn't exactly ideal, I know.

Summary: and so, the very dirty, dingy and much-mucked-with American Flyer K5 that I brought home from a train show on November 4th is now a nice 1/64 model that runs and looks very good indeed.

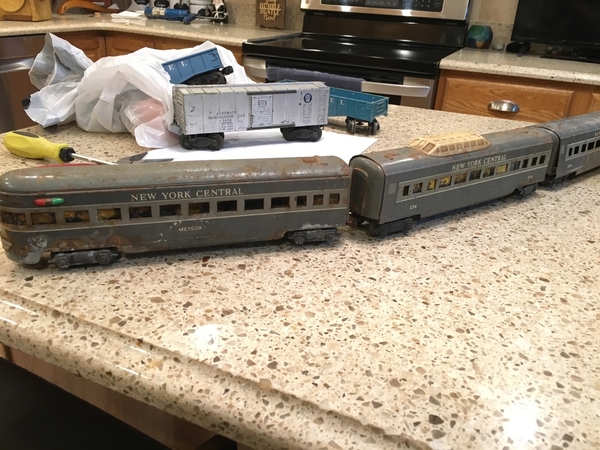

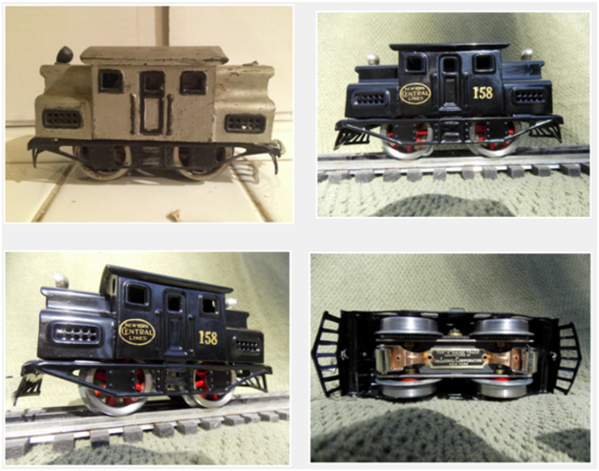

Was it worth all the time, work and expense I put into it? It was for me. I enjoy doing restorations, and I've always meant to get a Flyer K5 to go with the RDG 302 and NYC 322 that I restored some years ago. Along with pride of ownership, I now have pride of workmanship, which is important to me. And I hope that this real-time series of postings will encourage someone else to rescue another forlorn locomotive from oblivion.

For the future:

-- I will be mounting some track on a display board, and when I'm done, the K5 will finally leave my DVD shelf and take up residence on it when it's not actually running. It'll stand between its brothers, the 302 and 322.

--I already mentioned the possibility that I could replace the rear handrails with something thinner.

--And I have a sneaking suspicion that the wires I used for the tender/locomotive tether may be a bit too stiff for heavy layout use. I've already ordered some more-flexible silicone wire, in case replacement becomes necessary.

--I'd like to make the builder's plates on the boiler sides a proper bronze color, and I've bought a bottle of metallic paint for the purpose. But I won't get to that until I pick up a fine-point artist's brush.

--And of course, there are still some spots on the locomotive that need a bit of black touch-up paint (the pilot is one of them).

Thanks, Arnold, for starting this thread. I hope some of you have enjoyed this little saga. I had fun writing it.

--John, 12/8/2018