The magnet on my Fastrack uncoupling track is fried. How is the Uncoupler magnet assembled to the track piece? I want to take it out and rewind it. Visually it appears that only a few of the outer turns are the ones affected, so if I can get it out, it might not be too difficult to repair the magnet's windings. I couldn't find anywhere else on the web with hints or instructions on how to do this, but if it was assembled, there must be some way to disassemble it. For those who want to be sure I'm not barking up the wrong tree, I have continuity in the wires from the button switch. The magnet coil measures at 1.5 Ohms. I have no idea what an unfried magnet's ohm reading is though, but my guess is an ohm or two higher. I directly powered the magnet leads with 10-15 volts and there was no magnetism produced. How is this magnet assembled into the track? I can't see the lines distinguishing where the magnet is inserted into the track section's top or I'd have a better idea how to take it apart.

Replies sorted oldest to newest

Uncoupler magnets should be 5-7 ohms.

Looks like quite a bit of damage to the plastic as well, you might be better off just buying another one.

John is right. It is now a 5” fitter piece of FasTrack. If you do replace it, you should also replace the button with a better one, i.e. one that won’t stick.

The conventional wisdom is to toss it, but I don't like to do that for an item that has the same flaw. Do you guys have any idea how the magnet is assembled into the track section? Getting it out without destroying it is the challenge. Even if it's warped, that might be able to be heated and warped back up once it's out of the track segment.

ADCX, thanks for the information on the ohm reading of a good magnet. It won't help me this time, but such information is important to others doing troubleshooting.

The flaw is in the button.

Yes, usually the controller.

Although they look like the originals, they are really chincey.

R Lamparter posted:ADCX, thanks for the information on the ohm reading of a good magnet. It won't help me this time, but such information is important to others doing troubleshooting.

I haven't had time to study the construction of one of ours yet, if a get a look I will address that part of your question!

My hunch is that I need to remove the outer rails, (which I'm suspecting are hiding a seam) and the accessory rails and then the magnet can be removed from the top side. I don't want to start disassembling things unless I have to because there are a lot of connections to unsolder and it would still work as it is to unload old style cars with their own electronics.

I misunderstood. Sorry. When you said uncoupling track I took it to be that. Those controllers stick all the time. The operating track is more involved. I still think the controller must have been on too long for that amount of heat to be generated, either by sticking or being held.

R Lamparter posted:The conventional wisdom is to toss it, but I don't like to do that for an item that has the same flaw. Do you guys have any idea how the magnet is assembled into the track section? Getting it out without destroying it is the challenge. Even if it's warped, that might be able to be heated and warped back up once it's out of the track segment.

I repair lots of stuff, but I also evaluate the specific item and make a decision on fix or toss based on the likelihood of a successful repair. The cost of the item in question also enters into the picture, for a relatively cheap item, I'm more likely to come down on the "toss" side. In this instance, I deem that likelihood or a successful repair as being fairly small with all the warped plastic. I'm certain that the time involved in a repair of this type, even if successful, would be excessive and better spent on three or four repairs that have much higher probability of success.

Obviously, this is just my opinion, and I don't presume to tell you what to do or not do.

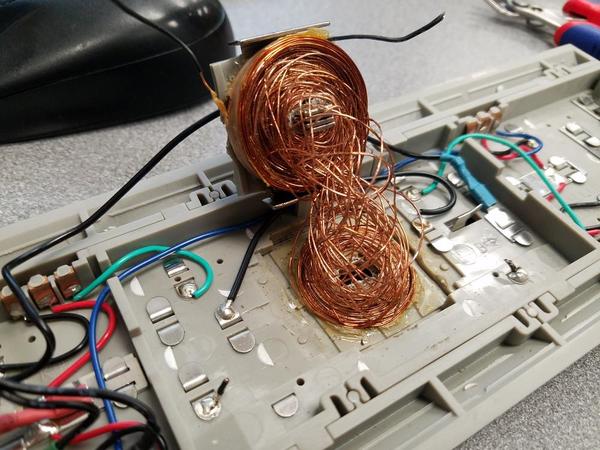

If these two tabs (would require unsoldering the right one) were bent 90 degrees upwards, does the coil assembly wiggle/loosen? There might might be corresponding tabs on the other side.

Also, if the nominal resistance is 5-7 Ohms and you're measuring 1.5 Ohms, it seems the "short" might be buried many feet into the winding...rather than just an easily accessible outer layer. Not Fastrack but in this recent roll-your-own uncoupling magnet thread, I estimated a Realtrax coil at 80 ft of #28 magnet wire, 600 turns, 5.3 Ohms. Would be nice to know the Fastrack coil parameters to add to the collective knowledge.

Attachments

Attachments

Dave that's a really helpful photo even if it implies the difficulty / impossibility of the repair. Knowing that it's just glued, it seems that the approach has to be to get under the glue first. In a commercial sense I agree with John that this is not economically repairable, however when you're retired and have always been one to tinker...... It was a Christmas present to my grandson last year.

Having seen Dave's photo, I started to work the edge of the coil up, first with a small spatula and then with a putty knife with a slightly thicker blade. I was able to sneak a broad tipped screwdriver underneath and twist to pry it off the plastic a little. This is as far as I wanted to go tonight. I wanted to prove the concept that it can be lifted and sleep on thinking about a better way to do it. Paint thinner isn't likely to dissolve/melt the plastic, but depending on the glue it might soften the glue. A heated spatula, somewhat under the melting temperature of the plastic and the wire's varnish might work. If I'm successful at rewinding/repairing this, it's getting a resettable fuse soldered in so this doesn't happen again.

Attachments

I renew my advice. ![]()

Not sure a fuse will help. It's the heating over time on that does the damage.

A properly sized PTC is probably a better choice for protecting the coil.

What's a PTC stand for John? It will probably be obvious when you tell me, but I'm blanking at the moment. The idea for an automatic resetting fuse (0.5A) came from a message somewhere else. I haven't made much progress today so far getting the coil off.

These will break the current when excessive current is detected and reset after the overload is gone. I'd try a 1A trip spec for this application to see how that works.