My GTW Trenton & Western Layout is an "around the walls" track plan, which means you either have to crawl under it or build a lift-up section to get in the room.

I'm building a lift-up benchwork section with two Atlas Pratt Truss kits.

I'm trying to make it so you can't easily see the gaps in the benchwork or scenery and not see the hinges at all. Needless to say this makes things more difficult, but I thought I'd share how I've done things so far.

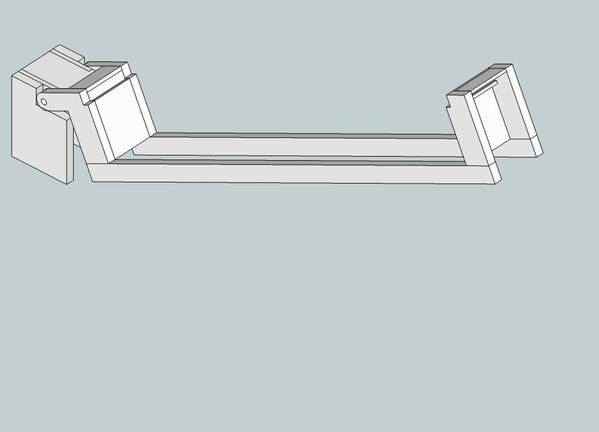

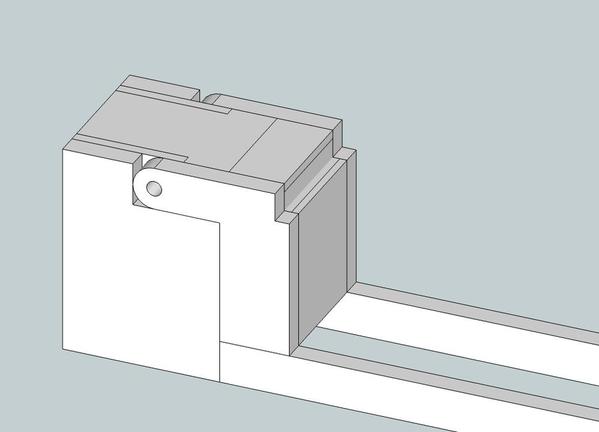

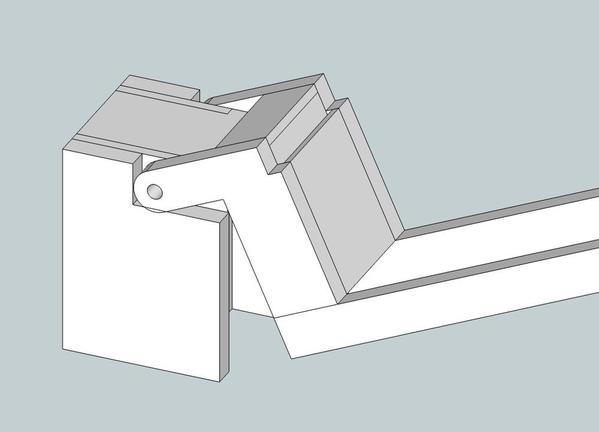

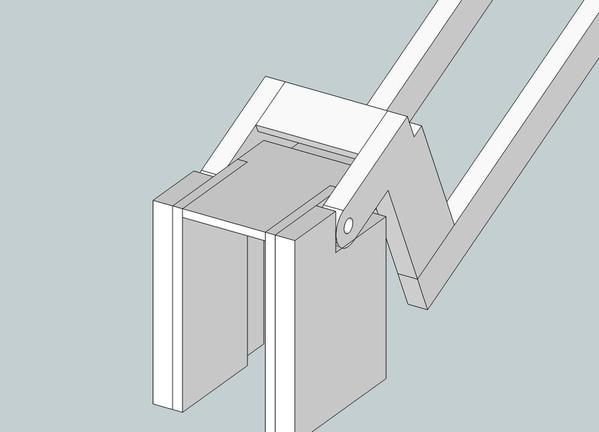

1. I used Google Sketch Up to mock up the concept

2. This is a view of the main span. There are two of these parallel to each other.

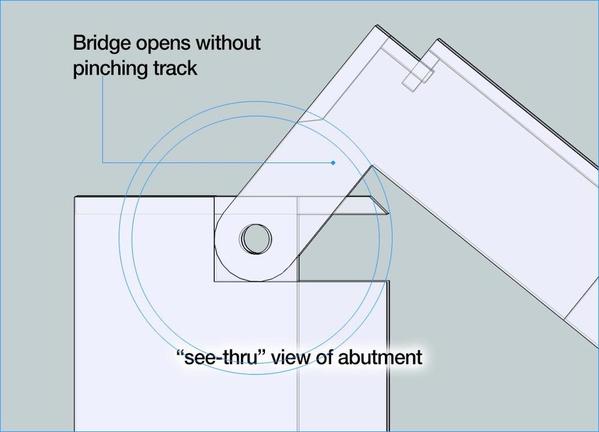

3. Here's how the span lifts open.

4. A close up of the "seamless" abutment. The vertical seam on the sides will be hidden by a thin sheet of styrene that is painted to look like concrete. The track will need to be back cut at a 45 deg. angle at the seam.

5. Here you can see where the pivot point and the seams are. The top deck seam will be hidden by the track work, both of which will need to be back cut at a 45 deg. angle so it won't bind up. The key to having this work is to keep the pivot point both below and behind the seam.

6. A reverse angle of the span opening.

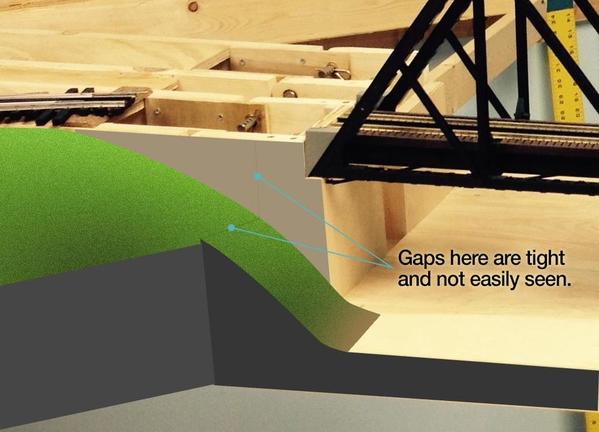

Here's a few shots of the work in progress:

1. The real thing... FINALLY! It took all summer for me to test and make things work in "the real world', but planning it all in Sketch Up really saved me lots of hassle!

2. A close up of the pivot points (cotter pins and bronze bushings) that serve as "hidden" hinges.

3. Lastly, Sam helps me to do a test. The whole thing is a bit heavier than I had hoped, but not difficult to lift at all. The bridge is not attached in this test, so we didn't go the full 90 deg.

Anyway, that's all I've got for now. Hopefully I can find some time to get back to work on this over the winter!