On the S-CL Modeler forum someone posted about a guy that was offering the shell for the motorcar in HO and S scale. I contacted him to see if he would/could do one in O-scale. Here's what he sent me last night:

He said he was low on white filament but had plenty of purple so i asked him to make it all in purple. He had to make it in pieces then join them together, when I enlarge the photo I can't see anything but fine details. It should be approximately 18" long.

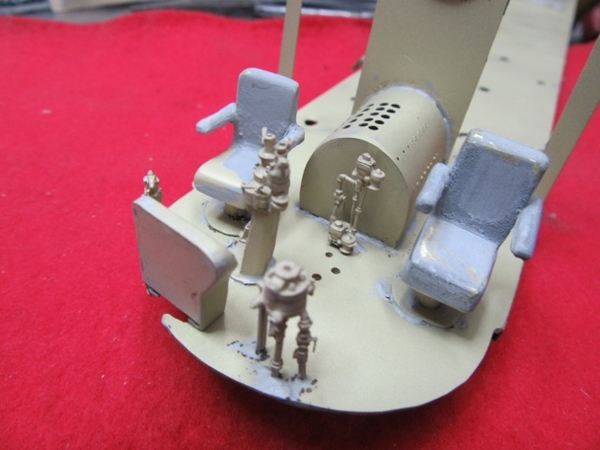

He said he would ship it out next week so I hope to see it soon. I'll be using the trucks off my old Weaver RS3 and need to make a floor, underframe, and interior, plus a few other details.

I only know of one other O-scale model built, scratchbuilt by one of the members at the Hamlet Railroad Museum.

This will make a fine addition to my collection. I'm also going to see if he is willing to do the streamlined Pacifics Seaboard had, maybe to put on the kinda new Williams by Bachmann 4-6-2:

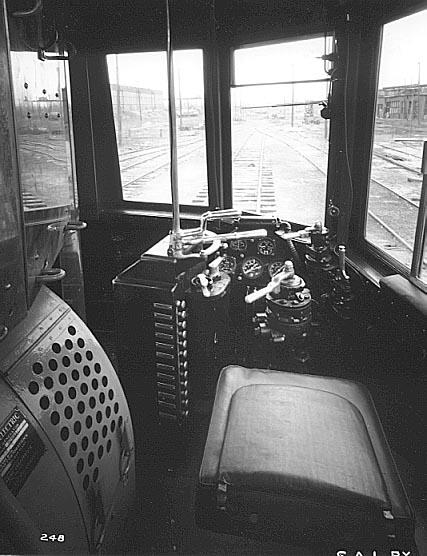

Here's what 2028 looked like in service: