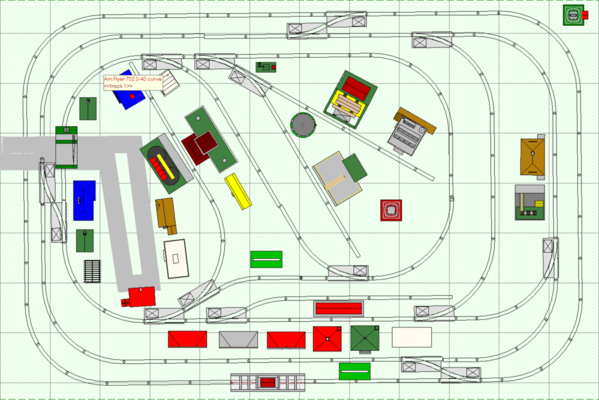

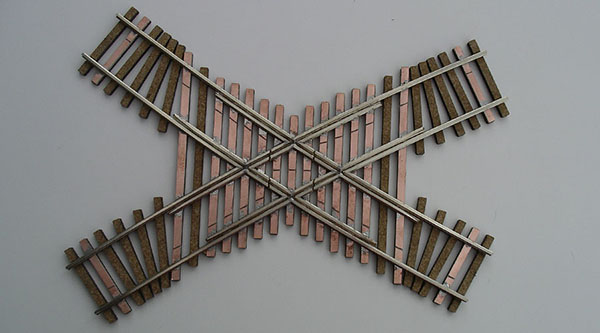

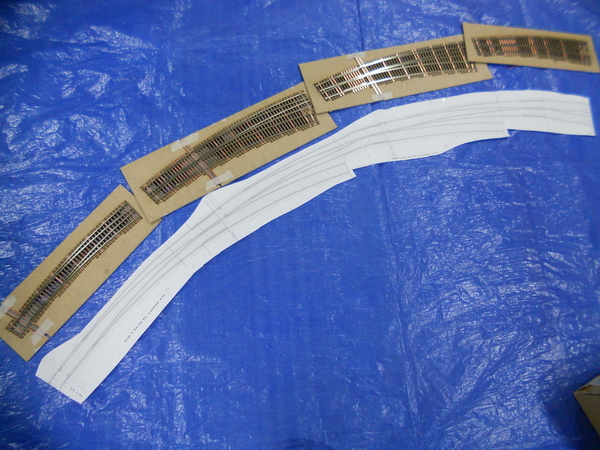

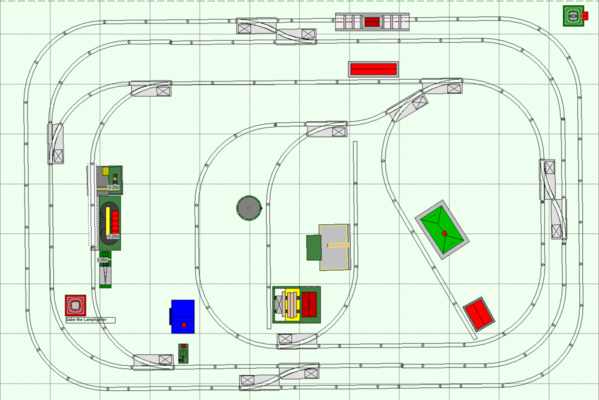

One of the working from home people, but without the long commute I have the time. My problem, as I have mentioned elsewhere, is convincing myself that it is okay to lay out the funds for the next step, buying the track, which even on a relatively modest layout can be expensive (I am likely going to use Ross sectional and curve pieces, with gargraves for the straights). One of the frustrations of the time is that when I want to do something that requires materials, it isn't as easy as popping out to a store on a whim (for any kind of projects, not just trains), and with ordering stuff it takes time plus with people ordering truly essential stuff I get concerned about flooding shippers with what I have to admit is non essential stuff (unlike the dog chews that if I don't keep in stock, will mean two 100 pound dogs gnawing on my leg, or worse, looking all sad and depressed at my wife, who will in turn gnaw on my leg until I order them *lol*). Then too I am coming into the outdoor season, that involves such wonderful things as powerwashing the siding, fixing a concrete patio, building a ground level floating deck, etc.

On the other hand in the past weeks this has served as a refuge, plus I have accumulated a lot of knowledge that once I get over my reluctance to spend on the layout, will help a great deal as I start working on it, and just to have some moments when I don't have to think of the real world is a blessing.

@Monsoon, the travel trailer in one of your pictures, is that scenic express? Would be cool to have something like that as part of the scenery on my projected layout