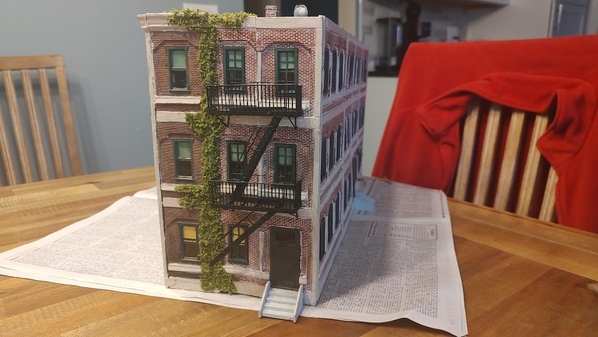

My simple Masonite and brick paper buildings for my 027, 1950s layout are not of the quality, craftsmanship or detail of most of you real modelers. We have some super talented modelers here on OGR forum.

My construction is typical of that used in the 1950s for my 1950s style layout and I have two of the buildings my father made in the early 1950s for me and my brothers Christmas 027 layout. I will share them later.

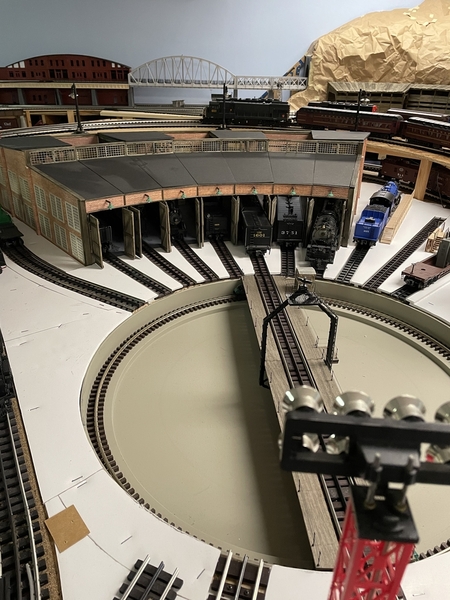

One of my first buildings made for my layout was a four stall round house to serve my scratch built operating $10 turntable.

The first consideration in building a $10 roundhouse is to decide how many stalls the RH will have.

I think the minimum that looks good is three. Many more can be added than three but I find that you cannot see and enjoy your engines as much when they are in the RH as all that one sees is the engine fronts. I decided to make my RH a four stall one and I am very pleased with it. It has a good shape verses a three stalls and fits my area very well.

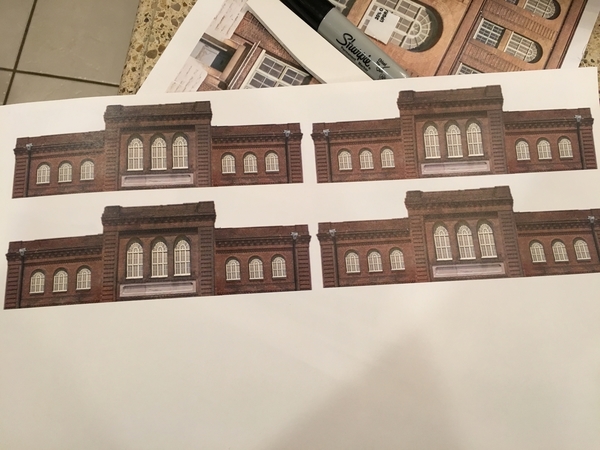

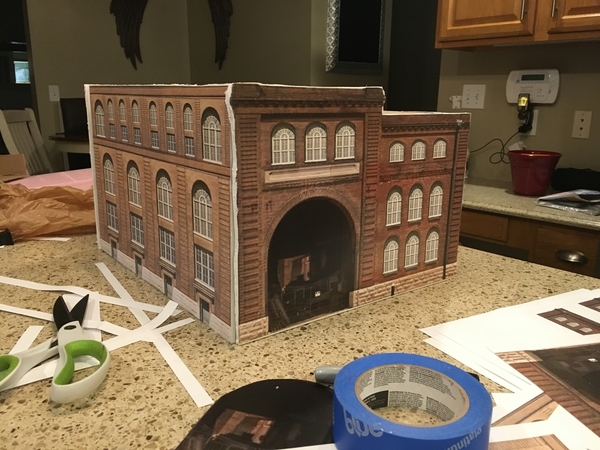

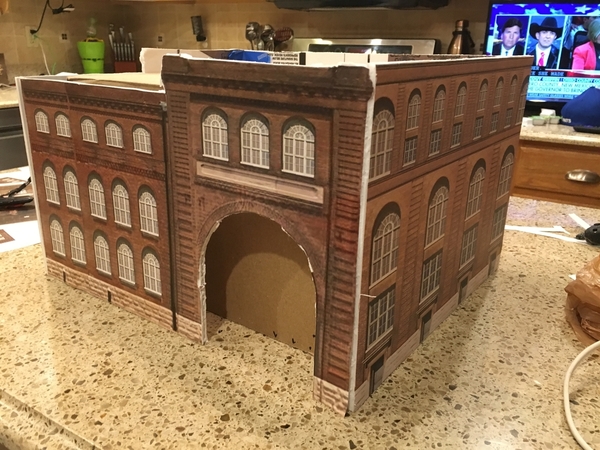

I like the stepped roof style RH and I like lots of windows so as they are typical of the era as electric lights were not all that common in the early times and windows provided daylight. I have windows on both sides, all along the back wall and on the stepped roof wall facing the front. I did not leave room or have room for a shop or tool room that many RH have.

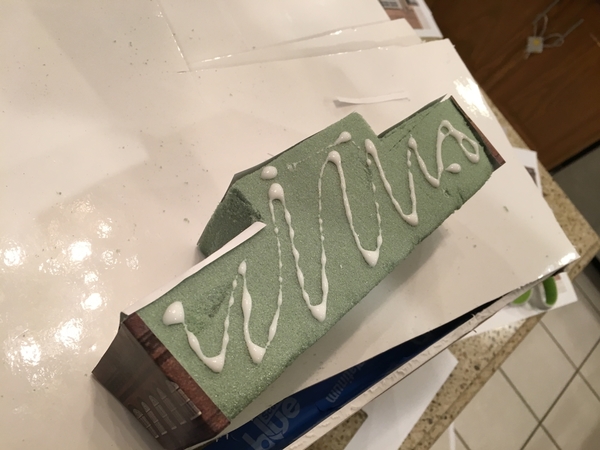

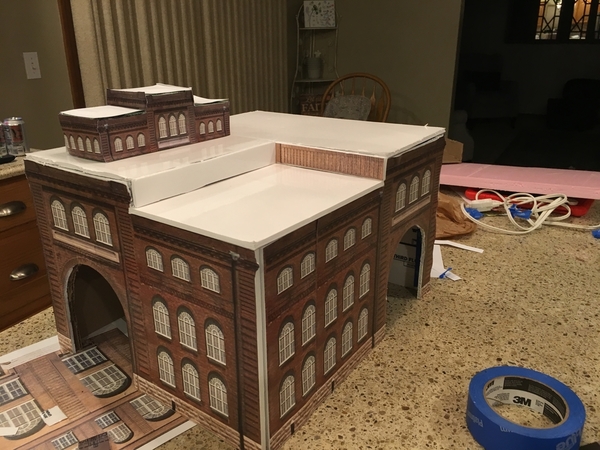

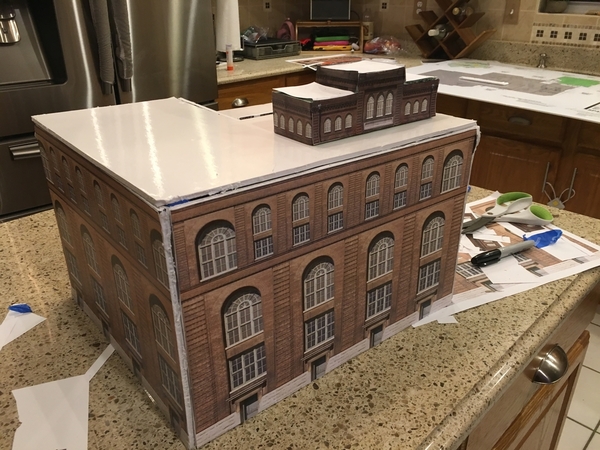

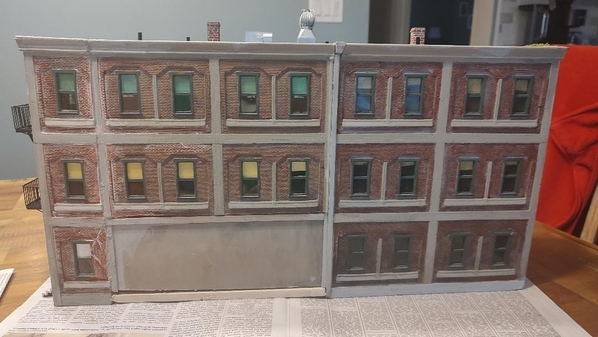

My roundhouse is made from my typical 1/8 inch thick, one side smooth Masonite tempered sheeting. A sheet costs about $13 for 4ft x 8ft sheet and you will only need one half of a sheet or less. I cut this with saber saw, or jig saw. I used my old Craftsman 18 inch jig saw with 1/3 hp motor, now out of storage, to cut out the windows after drilling a hole to allow get the blade in the window area. You can use a saber saw for this if that is all you have. The smooth side of the Masonite is put on the outside of the sides and back wall. Some 1/8” Masonite strips were used to reinforce the bottom and door frame.

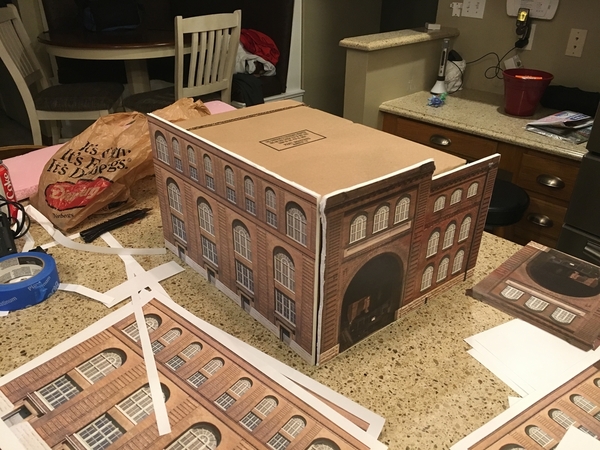

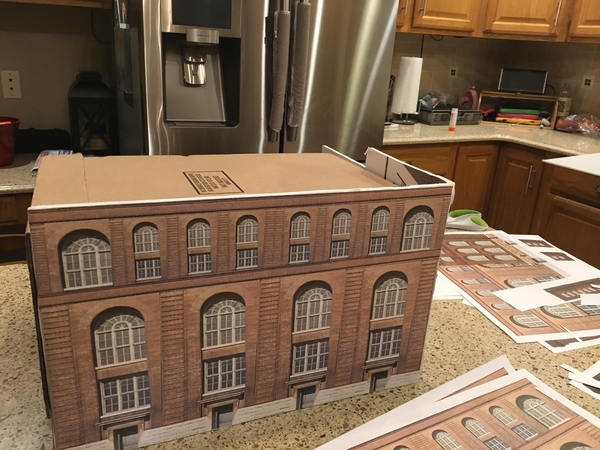

Front of Round House

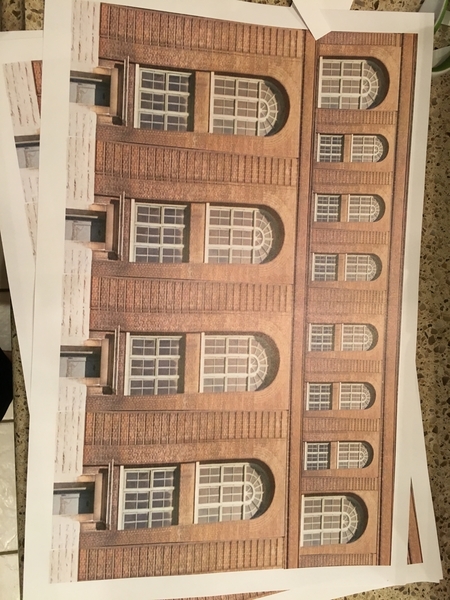

The outside walls will be covered with modeling brick paper, glued on with Elmer’s white glue after the building is assembled with Elmer’s glue.

The roof is made from Masonite too but the rough side is up to be the exposed roof surface, to simulate gravel on a wood and tar paper roof. I have a step in the roof with windows in the bricked section between the two roofs so the roof is made in two parts.

Four Tracks and four Stalls in Round House

You can see how I determined the size of the RH by fitting it in over 4 sections of track. I made sure not to include my one section where I can drive on the TT and directly to this one section with a long consist of engine, coal tender, wrecking crane car and wrecking caboose.

The picture below shows how I had to cut out part of the rear of the RH to go over a Marx switch machine housing. It also shows I had make sure the RH did not get too close to the tracks. It is a tight and custom fit.

Rear of Round House - wall over switch machine, Electrical connector (from 9 volt batteries) for RH lights right of switch

I assembled the RH with Elmer’s glue and added plywood angles to strength the wall to roof joints. I painted the inside walls brown and the inside roof light gray to better illuminate the inside. The outside of the roof was painted light gray, with a dusting of black paint to be dark dirt. Then I installed the brick paper doing a good job around the windows.

The windows are made from clear plastic sheeting from boxes lids from toys or other heavier clear plastic. The windows had panes made from black 1/16 inch auto pin striping on the inside. The windows were glued on the inside with "Pliobond" rubber cement, but contact cement or Aleen's Tacky glue will work.

Inside RH showing Roof and wall braces, windows and some lights

Picture showing double thick front wall and thicker bottom brace. I painted the center of the tracks in the RH black to simulate a pit below the tracks to let workers work on the under side of the steam locomotives (shown in picture below).

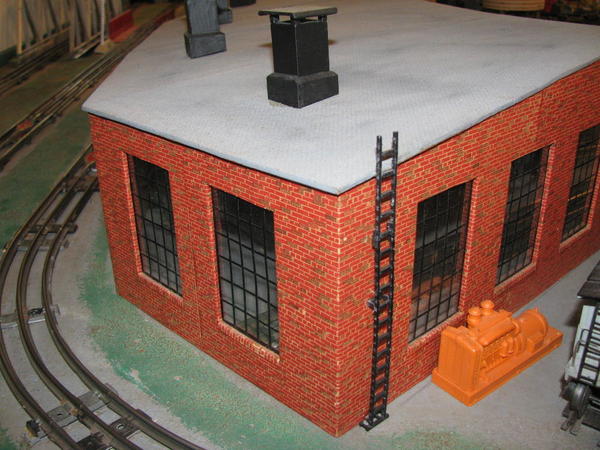

I made RH stacks, with covers to keep rain out. The stacks are to remove smoke for the steam engines. Balsa wood was used to make the stacks. I like the square style stacks better than round ones. Rain covers for the stacks were made. I also installed a ladder or two to get on the roof. Ladders were made from N gauge railroad tie plastic strips with the rails removed and every other tie cut out with a pair of diagonal wire pliers and trimmed with a X-acto knife.

Ladder, stacks and Roof, and also emergency generator from Lionel searchlight car

Close up photo of a Stack with cover and dust on top!

Lights were installed in the ceiling of the RH in two rows and are operated by a slide switch on the control panel. I am big on night train operation with the room lights dark or dimmed and lots of controlled lights in all building, flood lights, street lights, yard lights, cars and engines, etc.

See how the lights let the engines show up in the RH in a semi dark room

Photo showing the balsa wood TT operator shack on TT bridge and view into RH.

Photo from outside into lighted up RH

Another neat photo of lighted RH in semi darkness, just to encourage you to build a TT and RH

I chose not to make doors for the front of the RH as I wanted to see the fronts of the locos inside and I would have had the doors open most of the time and they would just get in the view and way.

I love my round house and it is my favorite building on the layout and the most fun and satisfaction to build.

Charlie