I agree Arnold. My start at kitbashing first destroyed two pricey kits, so I entered my design with some serious trepidation. Most of these kits are pretty expensive so you have to enter a kitbash with a strong stomach or bank account.

EmpireBuilderDave posted:I agree Arnold. My start at kitbashing first destroyed two pricey kits, so I entered my design with some serious trepidation. Most of these kits are pretty expensive so you have to enter a kitbash with a strong stomach or bank account.

Yeah. By my thinking, "kitbashing" is best practiced using random boxes of mismatched Plasticville parts, at least at first (look under the tables at the train show). This greatly lowers the stakes and makes experimentation and practice much more palatable.

A close relative to kitbashing are the so-called "craftsman kits". These are usually a box of pre-cut raw materials, and they are another "ice breaker".

Arnold's comments point out the fact that when you are buying any kind of kit, you are getting two different things: (a) a box of parts and (b) a carefully-thought-out design for a structure. These are two different things, and for many beginners "b" may be just as challenging as "a". Another way to address this is to scratchbuild a REAL building, working from photos. That is what I did with my gateman's shanty shown above. This lets you concentrate on materials and skills--inheriting the design from the architect of the real structure.

I have been "kit bashing" since a kid, turning my disliked Marx #21 into a double ended/cabbed diesel, uh, not particularly successfully. I have lots of practice, and attack expensive kits with no trepidation. I like them to be "different". Might be good idea to start small, and work up. But if you can make today's trains' electronics work, gluing together a box of sticks is well within your grasp.

Homemade Coal Mine and Coal Loading Station Operating Accessory

A Bachmann Coal Station was used to make a Coal Mine and Coal Loading Station operating accessory building that can load coal into a coal car remotely.

The Bachmann Coal Station kit was used to make the Coal Mine Entrance into the underground mine in the mountain.

A new “A” frame roof was built for the top out of 1/8 inch Masonite with a window in the end and the end was scored to be vertical siding. The roof was roofed with some of the kit roofing.

The Coal Loading Section was also made of Masonite. The outside walls were scored with a knife to be vertical siding. Windows were in the installed in the side and end walls.

A slide gate valve was made of plywood and held opened with a rubber band. A 12v solenoid (DC solenoid rectified to AC) was use to hold the slide valve closed and to return the solenoid plunger out to engage a notch in the arm of the slide gate valve to hold it closed. A coal storage funnel was made from card board stock.

Picture of Plunger return rubber band, slide gate with hole in center and notch for solenoid plunger, black solenoid and card board coal funnel is shown below. This rubber band holds the solenoid plunger in the notch in the arm of the gate and keep the hole closed, ready to hold and drop coal. See the wire in bottom of cone tied to the solenoid plunger which is operated to break up coal jams in cone. The black bridge rectifier can be seen that converts the DC solenoid to operate on AC.

This picture shows the slide valve closed (hole in slide gate is not under the funnel hole and the solid part of the slide gate is blocking the funnel hole) and the solenoid arm is holding the slide gate closed.

This picture shows the slide gate open (the slide gate hole is now under the hole in the funnel).

Picture of slide gate return rubber band. This makes the slide gate valve stay normally open and pulls the slide gate to open when the solenoid is triggered. Both rubber bands are easy to replace as the are in open screw eyes and around posts and last a few years.

PS: Recently (9-4-2017) it was not dumping. Turns out a plot of piston stoke from the magnet shows the most pulling power is when the piston is 1/16 to 1/8 inch out. It was much more so I had to modify by adding about 1/16 inch wood to the sloped part to make the trigger pull when about 1/16 inch out. That fixed it.

Picture of Power graph for Radio Shack Solenoid I used. You can see the pull in oz is much higher at 1/8 inch or small stroke.

Picture below shows the 1/16 inch thick strips of wood I added to the notch (appear whiter) to make the piston get more into the magnet and shorten the stroke for more power.

The coal is dumped into a coal car when activated with a push button on the control panel. A flat roof for the Coal Loading Section was covered with sheet metal roofing. Two 12 volt mini Christmas bulbs were installer in the outside corners of the floor and floor was cut out to illuminate the track below and inside the Coal Loading Section.

The picture shows the lights inside to light windows and cut through bottom to light coal car area below.

The picture is from the outside of coal mine loading station showing the lights working for inside the building and lighting the car below

Like most active accessories, the coal mine/coal loader should be located for easy hand access by the operator. The coal must be hand loaded into the funnel and the slide gate valve must be hand closed. Lionel plastic coal is used which came with a Lionel coal dumping car from the 1980s.

This was a fun project, especially figuring out a working coal car loading system.

Charlie

Attachments

Sound like it was a fun project and it looks really great. Nice lighting inside the building. I laugh when I see the little gimmicks people use to get things to work and I do the exact same thing. Stick a shim here or there and glue a piece of bent wood to make it work and fill a gap. Again great job kit bashing.

This diorama I built for Turkey Point Lighthouse Society and is displayed at Elk Neck State Park in Maryland. Park personnel were able to obtain the original blueprints from the national archives and each item was scratch built in 1/4 scale. Now back to the layout and to built some for me.

Attachments

I have two buildings from my brothers and my childhood layout on my layout. They were both made by our Dad, about 1950, using his childhood pedal powered scroll or jigsaw.

One building is a small train station, made from Masonite with the roof covered with model railroading roofing paper. The building has cuts scribed in to resemble siding. It has widows and other parts sawed out by jigsaw after drilling a hole and making inside cuts.

Train station built in 1950, roof paper was originally Green

Charlie

Attachments

The second building is a gas or service station. It is made from some type of thin wood covered with paper on both sides. The siding has model railroading brick paper glued to the side to simulate brick siding. The two garage doors have windows cutout with a pedal driven jigsaw. The rear windows were made from some plastic window covering with cloth support simulating window panes.

Gas Station built in 1950

These building construction methods lead me to build several of my building using Masonite and brick paper which is still available from hobby shops or on eBay. I got mine from Walthers years ago.

Charlie

It is time to revive this great topic and time for you all to update us on your latest Kit bash or scratch built building or other ones you have not already posted. I will start with an old homemade project.

Homemade Lionel Style Water Tower

A Lionel 6-12711 Water Tower Building Kit style Water Tower was made in the 1980s from 1/8 inch Masonite and brick paper covering. The tank was made from an oat meal round box and card board. The roof was covered with roof paper. Lights were added to the top of the water tank to illuminate the top of the coal tender from 12v mini Christmas tree lights. The spout was made from balsa wood. Ladder was made from cutting out every other tie from N scale rail tie minus the rails. I had the O scale door and window plastic parts. I think my homemade water tower is more handsome than the plastic Lionel Water Tower.

Below is the Lionel 6-12711 Water Tower Building Kit I modeled mine after (this one bought years later)

Charlie

Completely scratchbuilt newsstand. Styrene sheet and beams for support, colored plastic sheet for the walls, candy, magazine and newspaper images from the internet.

Attachments

Kitbashed and scratchbuilt subway lunch counter. Started with some laser cut counter kits and added details made from styrene and laser cut kit offcuts, plastic pen bits and bits of wire, some detail castings, and some internet images.

Attachments

Little scratchbuilt structure & scene....

Great modeling Joe and mwb! JohnA

@Choo Choo Charlie posted:It is time to revive this great topic and time for you all to update us on your latest Kit bash or scratch built building or other ones you have not already posted. I will start with an old homemade project.

Homemade Lionel Style Water TowerA Lionel 6-12711 Water Tower Building Kit style Water Tower was made in the 1980s from 1/8 inch Masonite and brick paper covering. The tank was made from an oat meal round box and card board. The roof was covered with roof paper. Lights were added to the top of the water tank to illuminate the top of the coal tender from 12v mini Christmas tree lights. The spout was made from balsa wood. Ladder was made from cutting out every other tie from N scale rail tie minus the rails. I had the O scale door and window plastic parts. I think my homemade water tower is more handsome than the plastic Lionel Water Tower.

Below is the Lionel 6-12711 Water Tower Building Kit I modeled mine after (this one bought years later)

Charlie

It's amazing what one can do with an oatmeal round box, cardboard and balsa wood!

Coach Joe

Neat idea on the scratch built Ice Cream Stand and great job on the O Clydesdale stable . Joe what did you make that swirly ice cream out of ?

Charlie

You guys have talent, great and inspiring work.

The only bonafide kitbash I've accomplished was on my first large layout and involved 4 IHC Engine houses to make a 2-story extra-long complex...lots of work and time. I detailed the interior as well, but I cannot locate the pictures right now. During divorce, I sold the entire complex, and would love to know if the guy still has it...cannot remember his name.

Attachments

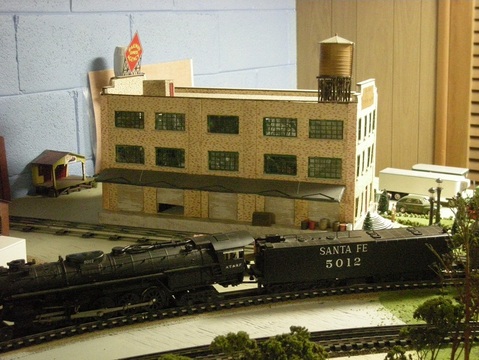

About twenty-five years ago Walthers offered an REA transfer building kit in HO. They had no plans to offer a kit in O so I built this for the Cincinnati modular layout. When I moved to Illinois I put the building on one of two spurs. Foam board and paper brick walls.

One grandson has a full wood shop and makes his own furniture. One of the structures on the roof is an empty SPAM can and the air filter outlet on the side of the top floor is a cap from a prescription bottle. John

Attachments

Attachments

Charlie, the ice cream swirl is made from closed cell foam backer rod used to fill larger gaps before caulking or sealing. As I coiled it I hot glued the layers together on the inside of the swirl. Some white paint and a decorative cherry finished it off. I wanted to try to add chocolate syrup dripping down the sides but couldn't quite come up with the right color paint. I thought about sprinkles but couldn't find a non perishable stand in and didn't want to risk using the real deal although enough clear coat may have prevented any issues

Here's three Lionel postwar modifications 145 with a prewar gate, Non operating baggage station modified using a 3444 cop /hobo car, and a 133 station modified to fit a 445 operating.

below is a short video of them working ....daniel

Attachments

What great scratch builds everyone. I love all the talent that this forum has! I built this tank farm about 2 years ago out of a couple of coffee cans and some old cardboard for the pits. The ladders were made by cutting square chicken wire.

The steps are from an old model car parts tree. and just some plain old red Leds atop!

Attachments

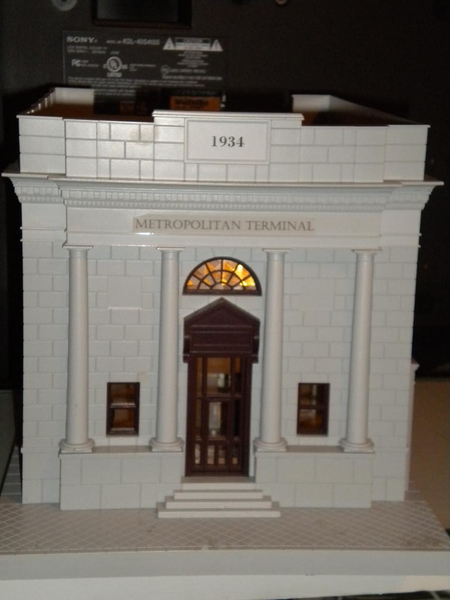

The MTH bank is a very versatile structure often used to make urban stations and terminals. Usually multiple banks are cut up and sections rearranged and combined if various ways to make grand looking structures. Do to space limitations I used one to turn a bank into Metropolitan Terminal.

The orientation of the structure is rotated 90 degrees making the side the front. I cut a hole in the side and used an Ameri-towne bank front to make the main entrance.

The bottom of the bank has a large opening to allow access to the interior lighting. I covered the opening and used a photo print to give the great hall a herringbone pattern marble floor. The ticket windows are a photo of a background used in an animated film. Sorry I don't remember which one. The round information booth is a photo of the Grand Central Terminal information booth wrapped around an icing cup from a tube of Pillsbury Cinnamon Rolls.

The front door has become a side entrance, elevated from ground level so a set of stairs was installed.

The large side windows, now rear windows have been covered with ConTac brand privacy film. A trick I learned from Alex Maille

Subsequent to taking these pictures, I re-purposed a piece removed to create the new front entrance to fill in the opening in the parapet seen at the rear of the photo below.

At some point in the future, I plan "tar" the roof in the future and add some benches to the waiting room.

Attachments

A Homemade Lionel style 193 Industrial Water Tower added to Old Train board

I have an American Flyer 772 Checker Board Water Tower on my new train board but none for the old train board. The AF 772 water tower came without the checker board decal or plastic film so I painted a checker board pattern on it. I had a Marx beacon light tower without a top.

I decided to make a Lionel style 193 Industrial Water Tower to fit on the Marx tower. I used a mailing tube to make the tank and card board for the sloped roof. I installed a flashing light on top from a mini Christmas tree light flasher bulb painted with red latex paint and installed a 20 ohm resistor in series to cut the voltage a little to increase the bulb life. I added a ladder up the side of the tank and plan to make a pump house to set at the tower base in the future.

I chose to label my Industrial Water Tower with the town name of Spencer, N.C. The location of the water tower will be on the old train board near my mountain as well as close to my turntable and round house. I picked Spencer, N.C. as the location because it is mountainous and the old Southern Railroad repair facility, Spencer Shops Roundhouse and Turntable are there. It is now called the North Carolina Transportation Museum with most buildings restored, and now includes many steam locomotives, diesels and old automobiles and planes. The N.C. Transportation Museum is well worth visiting as well as the General 4-4-0 in Marietta, GA. as we did in 2017.

Lets hear from some more of you great OGR forum builders.

Charlie

The Blooming Mill (left) is scratch-built using styrene walls and roof panels. Underneath, its skeleton is foamcore and wood. The larger Open Hearth (right) is entirely scratch-built using styrene shapes, walls, and roofing. There are some 3D-printed items within.

George

Attachments

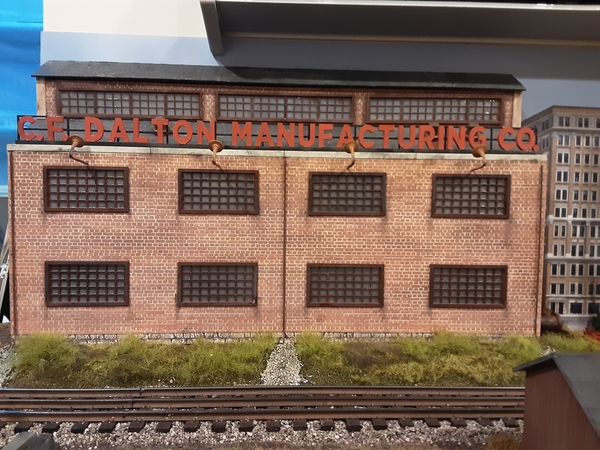

Homemade Industrial Building with Purposes

The layout has a hidden track behind the background that leaves a hole that needs to be hidden. It was decided to hide the hole by an industrial building. This building was made from 1/8 inch Masonite with brick paper covering the sides. The main outside loop track goes through this building too. Arch top windows were added and made from plastic sheeting and panes from 1/16 inch auto pin stripping. Vent stacks were added to the roof. A fake roll up door was added to the open ends of the building made from wooden dowels. A section of flat building was made to be the building and installed against the background to give the appearance of a larger building.

I ran out of the original brick paper and had some made with a color copy machine, but is not a very good match and appears too pinkish in pictures below.

Three sections of the hidden track, located at each end and in the middle of hidden track, have isolated outside rails to trigger a track occupation signal to indicate if a train is present on the track since the track cannot be seen. The signal power is controlled by the round house light switch. The signal is mounted on the left end of the industrial building, in full view of the engineer. 12 volt mini Radio Shack bulbs of red, yellow and green are used for the signal. Each bulb represents a section of hidden track that is occupied, and all three “on” mean the track has a hidden long train. The lights also indicate the progress of a train moving on the hidden track.

Charlie

Growing up, there were street corners dedicated to veterans. I've added a few to my layout. Frodo Baggins and Sam Gamgee are from "The War of the Rings". The late Queen Elizabeth II was the last World War II veteran on active duty as Commander in Chief of HM Forces.

Attachments

I made a steam boiler plant out of a small Lionel building to heat my Maintenance Facility. Probably was a small office building. I stuffed a smoke unit in that I found on A..zon which is actually for a radio controlled tank. The stack is 1/2" EMT conduit with an LED blinker wired up the middle and mounted on top. Smokes great and it was fun to build!

I don't use track voltage. I used an old DC transformer from a portable phone for the smoke unit, which I run sporadically. The LED blinker runs off a USB cell phone charger @5VDC and I seldom shut it off. Blinks all the time, just like the LED in your computer.

Attachments

Attachments

Steve C.

I love it, kit bash Plasticville and homemade. Great job on all the above posts.

Charlie