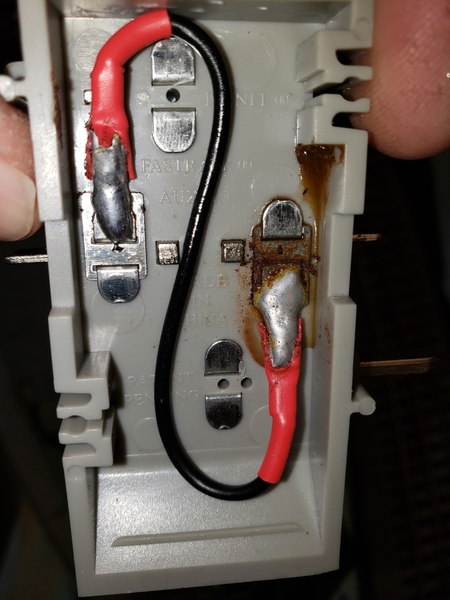

I know this topic has been discussed before. For example: the type of solder and flux to use on which type of metal. That part of the conversation is useless to me now that I have everything soldered! Lol, My question for the forum is.

1.) Is this just surface rust? And nothing to worry about?

Or

2.) Is the rust going to continue to eat away at the connections until it interferes with continuity?

Note: Layout is in a well controlled environment. No humidity or drastic temperature changes.

Thanks for your feedback!