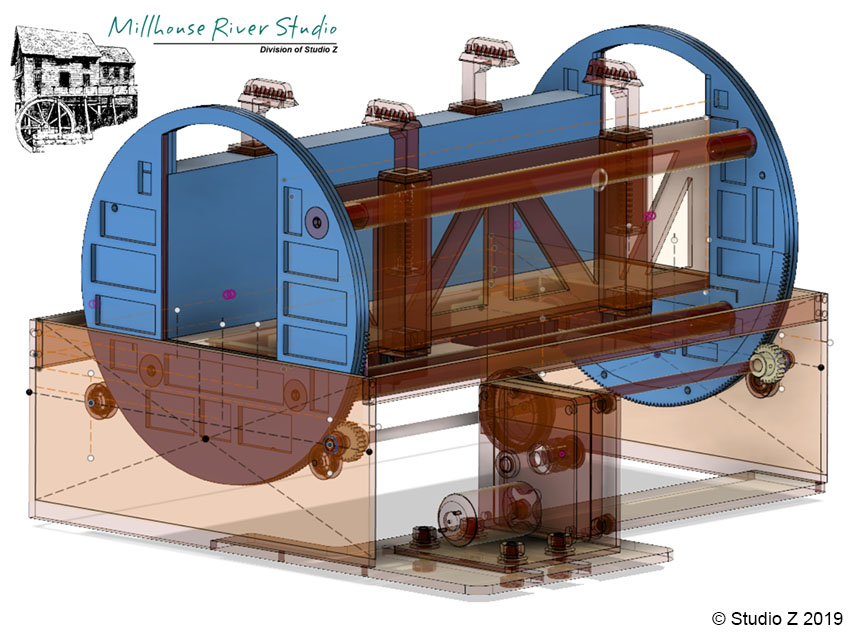

Good morning ladies and gentlemen. I thought I would share what we have been working on. We are in the process of building a new rotary coal tipple . It will be built from aluminum just like our turntables and transfer tables. We are making this so that it can be used with all the manufactures rotary cars, even if you have a mixed train of them. Here is an image from CAD to give you an idea of what it'll look like. Our design will allow the use of scale coal without issues of jambs. We also have plans for additional pieces to compliment the coal industry on your layouts. These include an auto indexing sled to pull cars though the tipple, a flood coal loader and operating conveyor belts for transferring coal . We are working on finishing up the tipple in time to show it off at October York. There is definitely a lot of work that goes into designing these pieces, so we will get them to market as soon as we can.

Replies sorted oldest to newest

Looks great Al!

Al

The operating conveyor belt sounds interesting. Will this be made in a way it could be used as a stand alone accessory?

John

Outstanding!!!!

Nice! Now if you can only make a "universal" straddle loader ( a.k.a. Mi-jack) that will load and unload scale containers and trailers that would be awesome!

That looks nice.

tr18 posted:Al

The operating conveyor belt sounds interesting. Will this be made in a way it could be used as a stand alone accessory?

John

Yes, they would

Al, new coal items sound FANTASTIC!

Al, very nice!

Al,

Would you believe: My original layout plans for the Hidden Pass Junction RR included the Rotary Coal Tipple that had been announced by Lionel on the 2011 Volume II catalog, page 79. As we found out shortly afterwards, they decided not to offer the Tipple.

Instead, I used that layout space for a turntable – yes, a Millhouse River Studio 34” turntable. I have posted numerous pictures of this beautiful turntable, which doubles as an access hatch. The turntable also appeared on the cover of OGR magazine’s Run 292 June / July 2017 cover.

Now, where and how am I going to find space for your new Rotary Tipple? I have wanted a rotary tipple so badly that I have an almost completed design to build one myself, but have stopped short due to lack of space. But for yours, I may have to rethink the space search all over.

Alex

AL,

I did a bit of googling and it looks like rotary tipples have been around for some time. I model the 40-50s. So I do not have any rotary gondolas. Would your rotary tipple fit into a layout set in my time period?

Also, I have your TT, it is of course incredible. I have not purchased the indexer for it yet, but I plan to because I want the ability to control it with my CAB2. Will I be able to control the tipple with my CAB2?

thanks!

Ingeniero No1 posted:Al,

Would you believe: My original layout plans for the Hidden Pass Junction RR included the Rotary Coal Tipple that had been announced by Lionel on the 2011 Volume II catalog, page 79. As we found out shortly afterwards, they decided not to offer the Tipple.

Alex

I have one of the Lionel rotary coal dump (I'm not sure about the term "tipple"), so Lionel did indeed make one. There was a later version with command, I guess? Announced but not made? (Didn't care; had mine.) At any rate, they can be had.

Downside - I built part of my layout extension around this coal dump. Got a nice hole in the layout for it (didn't want the uphill/downhill thing). tested it (I had used it a bit years ago). All fit, all worked. Painted and weathered it to give it a 1950-ish look and lose all the 21st century safety yellow.

It then decided to self-destruct in both the hopper "grabber" mechanicals and the actual drive train (bad gearbox - goes an inch or two then stops except for the "click-click-click...." of the slipping/stripping gears). So, it will be eye-candy only. Or, it may be target practice one day. Repairable? Not really - and I am a believer in fixing things. Even if I got the parts, I wouldn't trust them for long. I know a way to simplify it to make it work manually (as in I control a motor and its speed, and the hopper "clamp" movement seems unneeded, as only one kind of car is to be used - a snug fit should do), but I'll never live long enough to get to it.

Ingeniero No1 posted:Al,

Would you believe: My original layout plans for the Hidden Pass Junction RR included the Rotary Coal Tipple that had been announced by Lionel on the 2011 Volume II catalog, page 79. As we found out shortly afterwards, they decided not to offer the Tipple.

Instead, I used that layout space for a turntable – yes, a Millhouse River Studio 34” turntable. I have posted numerous pictures of this beautiful turntable, which doubles as an access hatch. The turntable also appeared on the cover of OGR magazine’s Run 292 June / July 2017 cover.

Now, where and how am I going to find space for your new Rotary Tipple? I have wanted a rotary tipple so badly that I have an almost completed design to build one myself, but have stopped short due to lack of space. But for yours, I may have to rethink the space search all over.

Alex

That’s a great story about the layout Alex. I love seeing all the fun everyone has with their turntables. That was a nice cover photo you had. I think the tipple will be another hot item for everyone. My plans right now will be to have the indexing sled to pull the cars through the tipple as a seperate accessory, since a lot of people just won’t have the extra space for it, but you will be able to operate the tipple as a independent unit.

T4TT, I don’t think there will be TMCC control, but I will talk with my computer engineer and see what he says.

OMG, this will be a game changer, having operating SCALE equipment. ![]()

I'm probably 4 - 5 years away from building my retirement layout, and it would be sooooooo cool to have a tipple, conveyor, and a flood loader! ![]()

Jim

CSX Al, this is going to be fantastic, see you at York....Happy Railroading

Thanks Larry. I just finished up the last bit of assembly of files in CAD, now off to laser cutting all the assembly parts. Here is the screen shot of the completed assembly.

Al,

What would be a realistic date when you anticipate that the tipple will be available?

Thanks!

Alex

prrhorseshoecurve posted:Nice! Now if you can only make a "universal" straddle loader ( a.k.a. Mi-jack) that will load and unload scale containers and trailers that would be awesome!

I second this request. I’d buy multiple of these!

Ingeniero No1 posted:Al,

What would be a realistic date when you anticipate that the tipple will be available?

Thanks!

Alex

Alex, My plan is to have the working prototype at York. Once this happens I will be ready to start producing them. All the hard work is done.

Al,

Any idea of the footprint?

EMD posted:Al,

Any idea of the footprint?

The top plate that sits on top of the layout is approx. 11.75" x 15.75" . the outside of box that holds the drum is approx. 9.5" x 13.5" The motor mounting plate adds 3" off the box short dimension, but when installing into layout you would just insert this area first into hole of layout.

Al, maybe the drive motor should be mounted on the outside of one of the below ground walls. Just bring the shaft through the wall for the motor. My thoughts are that it would make for easier motor access and be a heck of a lot cleaner environment.

Dave, that same plate also holds circuit board, sensors and wiring hookups.

prrhorseshoecurve posted:Nice! Now if you can only make a "universal" straddle loader ( a.k.a. Mi-jack) that will load and unload scale containers and trailers that would be awesome!

PLEASE make an intermodal crane!!!!!! You could put a thin piece of metal in the top of the container and use an electromagnet in the gantry crane to pick it up and let it go. There is one in HO made by Heljan that I debated gutting and putting in an O scale version but $750 is a bit high to experiment with.....

https://www.walthers.com/opera...-7-16-quot-33-x-57cm

BTW, I have one of the original brass rotary coal dumps made by Harry Roberts if you would like to see it....

Thanks,

Randy

Here are some images of the one I have. It is all machined out of brass and then painted.

Attachments

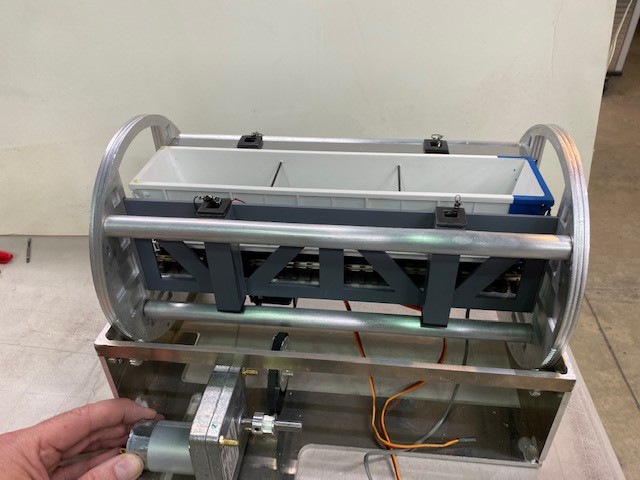

I stopped over to Al’s house the other night to check out a couple things on his layout. He took the time to go over the details of the tipple and showed me some of the prototype parts. All I can say is WOW! Be prepared for a great operating accessory and get in line. He’s going to be very busy in the near future!

Not all coal porters have the rotary couplers. So does this tipple rotate one car at a time? Does this require an engine to load one car at a time onto the tipple? On the other hand, if your coalporters have the rotary couplers, then a consist can stay coupled together. Am I thinking right. Guess I have never seen one of these tipples in operation. Sorry for the ignorance.

jini5 posted:Not all coal porters have the rotary couplers. So does this tipple rotate one car at a time? Does this require an engine to load one car at a time onto the tipple? On the other hand, if your coalporters have the rotary couplers, then a consist can stay coupled together. Am I thinking right. Guess I have never seen one of these tipples in operation. Sorry for the ignorance.

This isn't Al's tipple but you can get an idea about operations

Very cool video. Thank you. A few questions....I am guessing those hoppers were pushed up the hill with closed couplers which were not engaged? Or were those rotary couplers? I guess what I am trying to figure out is if someone buys one of these tipples, will you have to start buying coalporters with rotary couplers? I think MTH stopped producing the rotary couplers(I think).

Al - I'll be stopping by at York to talk, but after having your transfer table:

![]()

Thank you Jim Z., Ben & Jim S. ! All is going well, making a couple tweaks on a couple of parts. I am really looking forward to showing this at York. We are slammed in the shop with trying to get orders finished up before York and get this new tipple done. I will need a few days at York to recover ![]()

jini5 posted:Very cool video. Thank you. A few questions....I am guessing those hoppers were pushed up the hill with closed couplers which were not engaged? Or were those rotary couplers? I guess what I am trying to figure out is if someone buys one of these tipples, will you have to start buying coalporters with rotary couplers? I think MTH stopped producing the rotary couplers(I think).

Hi there. I work at a coal fired power plant that has one of the real thing. Out in the 12" to the foot world, there are several different manufacturers of the railcars themselves, with differing dimensions. The length is not standardized, which mean you can't guarantee you can dump cars without uncoupling.

Typically here we empty the first car in the cut, then push it through and uncouple it. Then back up so the rotary coupler(s) of the next car is hanging out one end. Dump the second car and push it out to the first one that got uncoupled. Repeat until the string is completed. I think we dump in 10 to 15 cars strings.

jini5 posted:Very cool video. Thank you. A few questions....I am guessing those hoppers were pushed up the hill with closed couplers which were not engaged? Or were those rotary couplers? I guess what I am trying to figure out is if someone buys one of these tipples, will you have to start buying coalporters with rotary couplers? I think MTH stopped producing the rotary couplers(I think).

Those cars are Atlas with the rotating couplers It should be very easy to put uncouplers on either side of the tipple This would allow uncoupling in position so no need for rotating couplers In our video there is an uncoupling magnet on the exit side of the tipple The cars come up the ramp coupled

Awesome Al!!!

JHZ563, Thank you for the picture and video of it in action.

Thanks Eric.

Amazing work, Al!

Peter

CSX Al posted:Thanks Larry. I just finished up the last bit of assembly of files in CAD, now off to laser cutting all the assembly parts. Here is the screen shot of the completed assembly.

Al, wow... that rotary dumper looks like it is going to be fantastic, can't wait to see more.

Thanks!

John

Al,

I will email you a few more tomorrow.

jz

It looks awesome, Al.

Peter

Al, something else that would be cool to add to your creation, would be a vibrator motor. I don't know if their used all the time, but during the winter months when the wet coal freezes to the sides of the hopper car, a vibrator activates when the rotary reaches full dump position to break loose the frozen coal and help completely empty the car out. If a motor was mounted under the tracks that was activated by a switch at full dump, giving the effect and the sound, it would be awesome.

Thanks for the suggestion Dave

Very nice indeed.

Dave Zucal posted:Al, something else that would be cool to add to your creation, would be a vibrator motor. I don't know if their used all the time, but during the winter months when the wet coal freezes to the sides of the hopper car, a vibrator activates when the rotary reaches full dump position to break loose the frozen coal and help completely empty the car out. If a motor was mounted under the tracks that was activated by a switch at full dump, giving the effect and the sound, it would be awesome.

I have been around a few coal dumpers, and the only ones I know that use vibrators are bottom dump systems. A rotary dumper like this uses a that shed to warm the cars up before turning them over.

That looks great.

Thank you guys.

JHZ, I received your photos today. Those are fantastic! I still would like to take you up on your offer for a tour of the dumper at your facility. I will call and work out a time later this week. Good to know also about the vibrator on the dumpers.

I did spend quite a bit of time today with my computer engineer going over the electronic controls and circuits. I also talked to Dennis Brennan today about the use of scale coal in the dumper. 1-100 ton car holds 22oz of real coal, which won't be an issue with our gear motor. Ran motor tests today and it looks so cool running. ![]()

Looks very impressive! A worthy addition to any layout. Looking forward to seeing in operation. BigRail

That is looking amazing!!! Can’t wait to see it in action!

Super nice Al!

My coal train wants one bad.

Attachments

Looks great Al!

Most impressive, wish I could see it at York!

Dave Zucal posted:My coal train wants one bad.

Wow Dave, your coal train needs one! 👍🏻

My wife and I stopped by Friday morning to see the rotary dump in action. It is an impressive and well designed piece of equipment. As promised, Al's prototype was fully functional, and he demonstrated its operation, and also showed how the built in safety mechanisms work. This system will work on just about any hopper, including two and three bay cars, and as noted above in a previous post, even in the real world, some cars need to be cut from the drag, as would be the case with most three bay cars, and all two bay cars. The hold downs are positioned so they will accommodate any length car. The rotation is smooth and prototypical. This is a winner! Great work Al.

Thank you Rail. It was great meeting you and your wife. Here is a video of the dumper at our display at York.

Thats awesome stuff Al! You cvould even speed up the rotation a little, and don't forget the sprayers to blow off the coal on the top rail once the cars are upright. ![]() https://youtu.be/DbJl_Astx_w

https://youtu.be/DbJl_Astx_w

Al, is it possible to increase the motor voltage to increase the rotary speed? I'll be dumping quite a few cars.

Thanks for the comments guys. I will have to check with my computer engineer to see if we can boost power going to motor to speed it up a little. If we can we would have to use a higher voltage power supply. I don’t know if that’s possible with the same power being reduced to power the boards.

Thanks Al for looking into that. Another option would be a different ratio gear motor. The motor looks like the same type used on a pellet stove auger. Very powerful little buggers. Great choice. If changing the ratio became too fast, a pot could be used to slow it down and allow us to adjust the speed to our liking. My plan is to dump through the layout, at a power plant, onto a cupped belt conveyor that will move the coal back to the loading area of the layout, at coal breaker, where an empty hopper car will get loaded with the coal that just got dumped.

I did make it to York and saw the very impressive demo. Good work!

Here is Al's next project: https://www.youtube.com/watch?v=jxxspw-K5GA

Hokie, neat project, but I've got my plate full ![]()

My next new item will be the flood loader, guys have a way to load their hoppers.

It will be similar to the structure Harry Roberts did in brass, but with a different shoot mechanism. Looking at a footprint of 6x12" with a hopper depth of 10" deep

I'm looking forward to conveyers> I have always wanted that but could never figure out how to make them.

Thanks for keeping us updated Al. Looking good.

I saw this at York and it is very well made and you will not find anything like it in the market place.

Hey Al, nice photo of the Harry Roberts flood loader. ;-) Reach out to me and I can point you to the guy who gave me that photo. He had it for sale but I could not afford it. I also believe that Harry had sensors that detected the end of the car to cut off the flow of the “coal”. Have a great evening, Randy

You can see the sensors in that photo. They are black and are located just under the catwalk on the model.

Fedex dropped off a highly anticipated package today!

Millhouse Studio tipple is in the house - up and running without issue on the repair bench.

Thanks AL at Millhouse.

Jim

Attachments

I model 1920's so it would be manual rope operated chute or steam donkey. Any ideas ?

Jim, Al may not be pleased to see a non-CSX hopper in there! 🤪 At least we know now that other railroads’ cars work in it!!!

Attachments

BigTruckPete,

Al is gonna have to suck it up! Come on its a Canadian National which is basically across the river from Buffalo....

Still working on getting it mounted in. It's gonna sit elevated currently, not flat. Just not ready to totally redesign the layout to change as of now. This is replacing the Lionel one which was about 2.25" taller.

Jim